Standard operation program generation system and method for machining of sheet metal stamping

A standard operation, program generation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving production efficiency and reducing human error operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

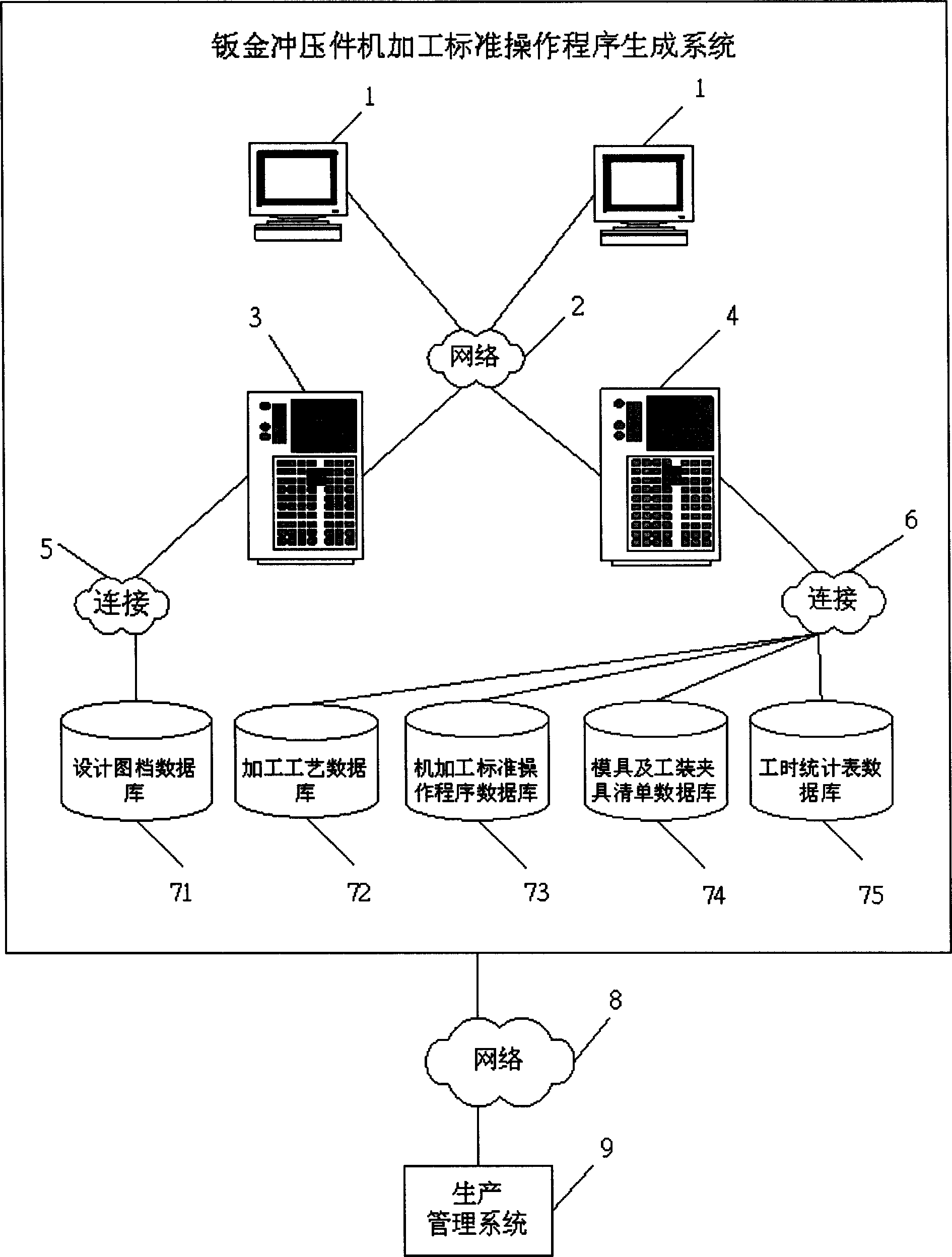

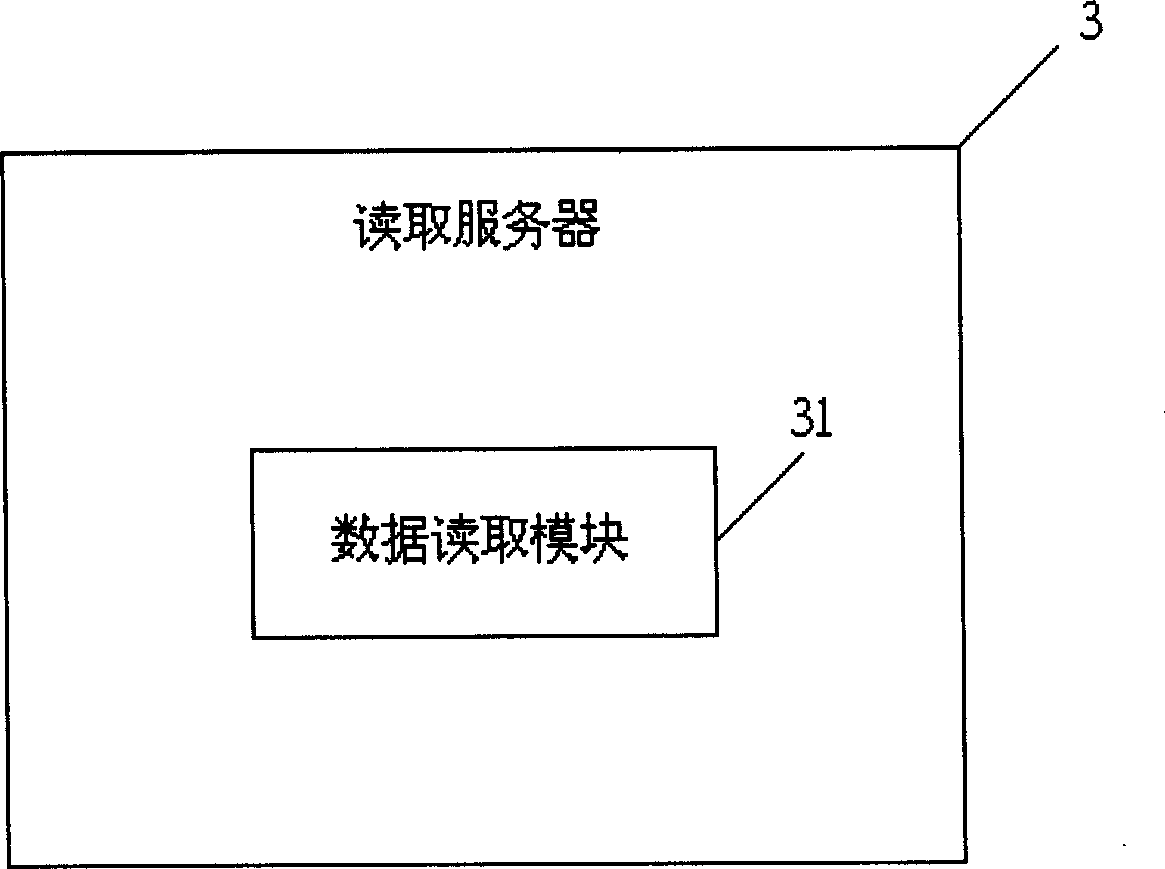

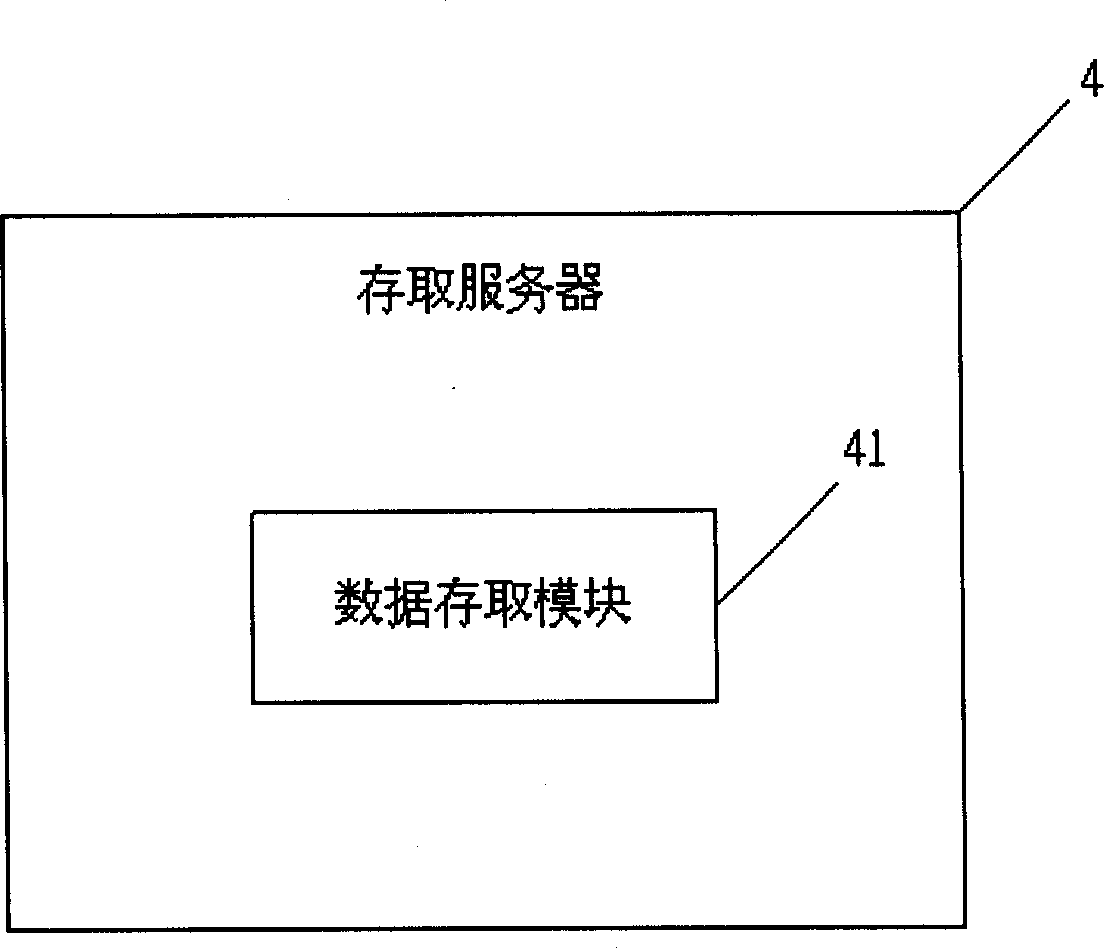

[0016] Such as figure 1 Shown, be the hardware frame diagram of the present invention, wherein client computer 1 is a kind of personal computer PC, is equipped with CPU, internal memory, hard disk, display and keyboard, mouse, and LAN network card is installed, and the AutoCAD software of Autodesk company is installed , for installation such as Figure 4The multiple functional modules shown provide an operation interface for the user. The network 2 is an electronic network based on the TCP / IP communication protocol. The client computer 1 can be connected with a reading server 3 and an access server 4 through the network 2 . The reading server 3 is used to read the CAD design files of the workpiece in the design file database 71 . The access server 4 is used to read and store the information content in the processing technology database 72 , the machining standard operating procedure database 73 , the mold and fixture list database 74 , and the man-hour statistical table data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com