Engineered meridian tyre blank molding method

A molding method and radial tire technology are applied in the field of tire manufacturing, which can solve the problems of low molding efficiency and hidden quality problems of tires, and achieve the effects of improving efficiency and increasing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

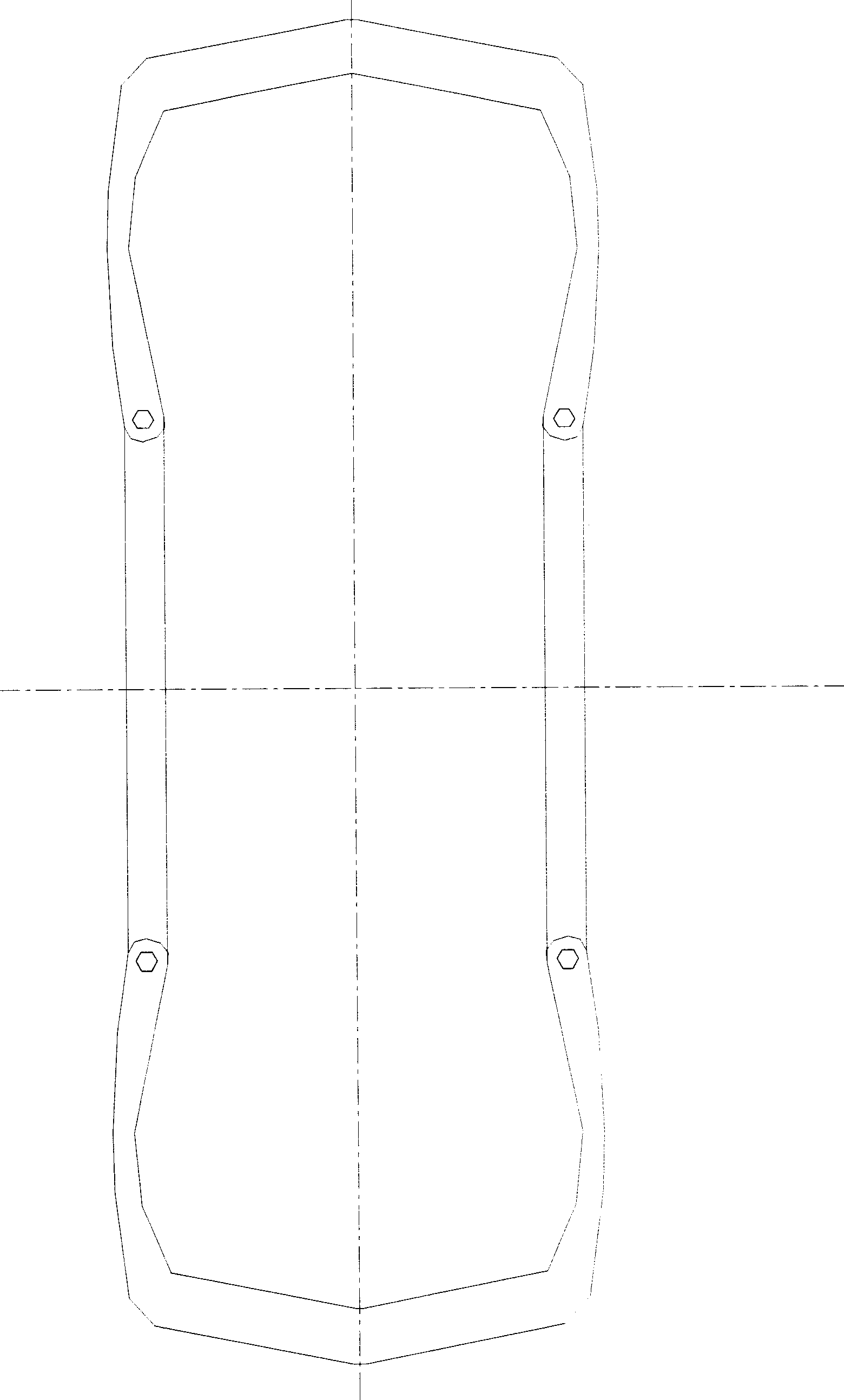

[0021] The segmented molding process of the engineering radial tire embryo of the present invention is to boldly and reasonably split the molding process of the engineering radial tire embryo, so that the molding of the engineering radial tire embryo is completed in three stages, that is, three-stage molding. The specific equipment used in the forming process, such as: simulation winding machine, flat drum, half-drum forming drum, gripper, clamp ring, spreader, reverse-wrapping capsule, belt layer bonding drum, and the structure of the shaping drum The structure is well known to those skilled in the art. The specific methods used in the three-stage molding process, such as: simulated winding, airtight rubber, carcass bonding, carcass finger wrapping, buckle ring, rubber core pressing, The operations of shoulder pad winding and carcass turnup are also well known to those skilled in the art. The present invention adopts three-stage, seven-drum forming, and is equipped with four ...

Embodiment 2

[0033] In this embodiment, the second section is composed of a subsection. In this subsection, only one semi-drum-type building drum with adjustable width is used to complete the molding operation of the second section of composite parts. In addition, other operating steps are the same as in Example 1. It is exactly the same, and the description will not be repeated here.

Embodiment 3

[0035] In this embodiment, the lamination method is used instead of the simulated winding, and the specific forming process is as follows:

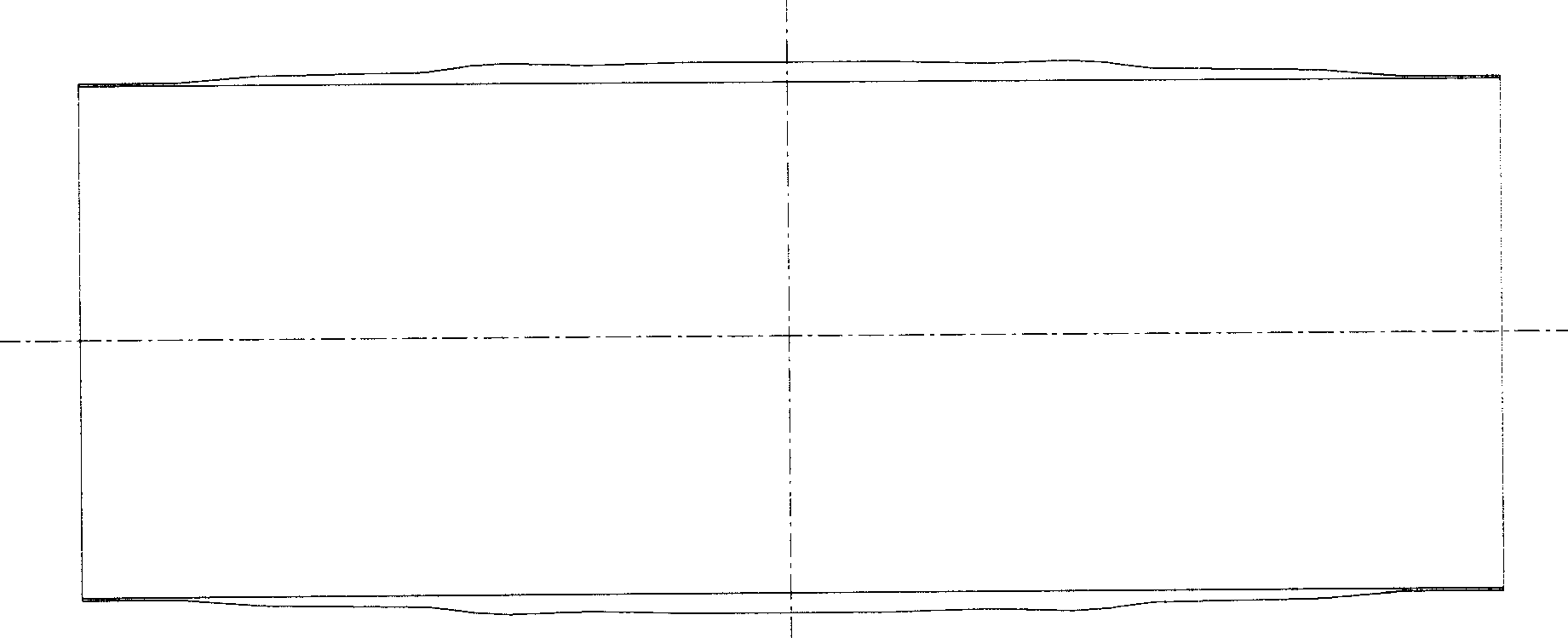

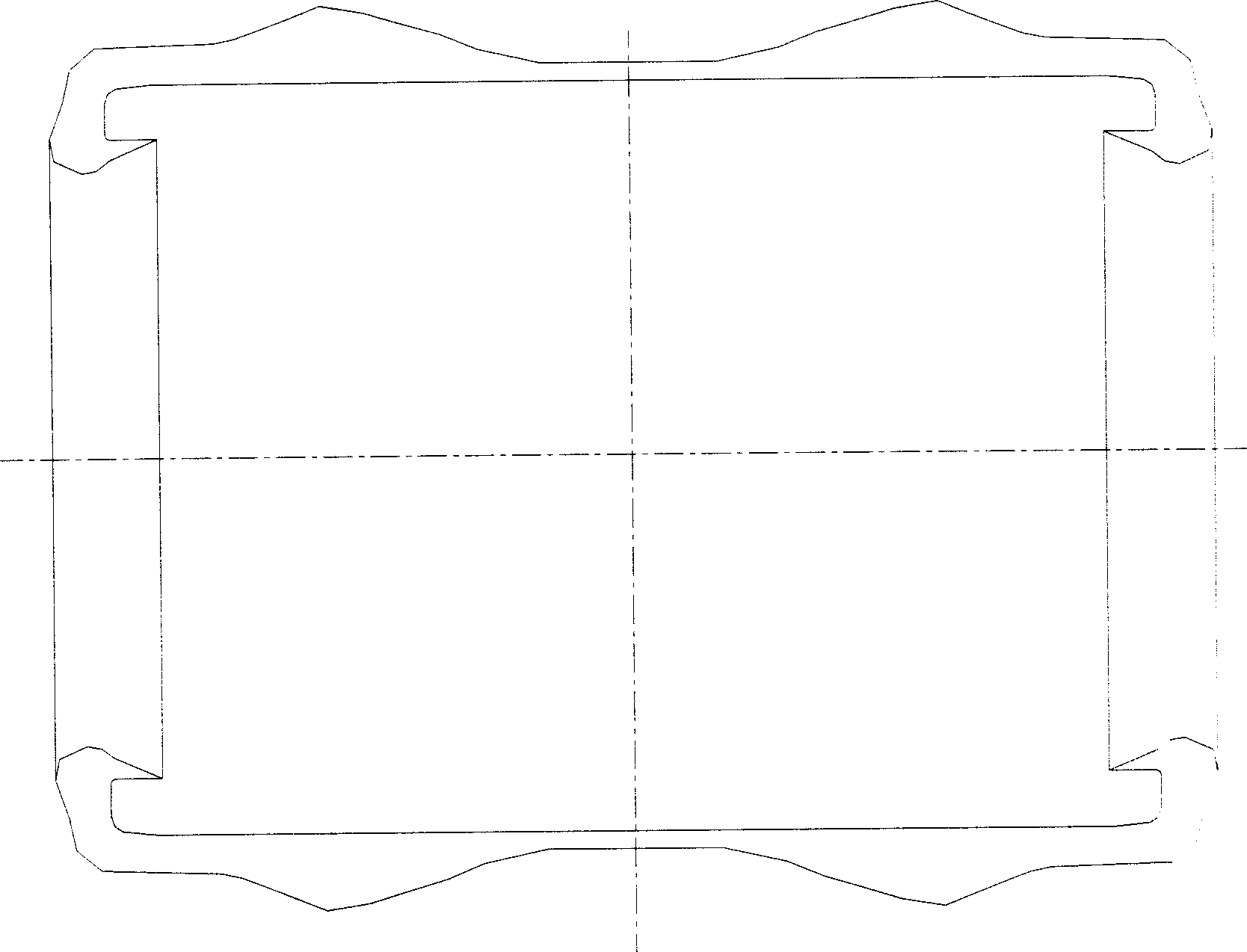

[0036] One section: use a flat drum with continuously adjusted diameter to carry out airtight glue, carcass lamination and adhesive glue lamination, and finally form a section of carcass tube composite (such as figure 1 shown), the working process is:

[0037] First, the diameter of the flat drum is adjusted to the working diameter, and the airtight glue is applied. After the bonding, the joint parts are processed and compacted. The carcass joints are sewed together, and then the carcass is bonded again with adhesive glue. Finally, a section of composite parts is rolled and marked with a pressure roller, and finally a section of carcass tube composite parts is bonded. A length of carcass tube composite is unloaded from the flat drum.

[0038] Second stage: Due to the faster speed of the carcass tube composite produced in the first stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com