Acid dye dyeable polyacrylonitrile resin production method

A technology of polyacrylonitrile resin and acid dye, which is applied in the fields of dyeing, textiles and paper making, and can solve problems such as dye spots, fiber white spots, and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

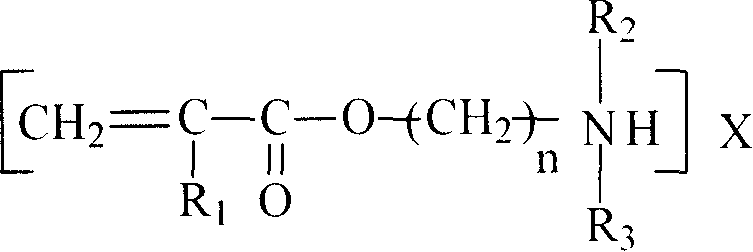

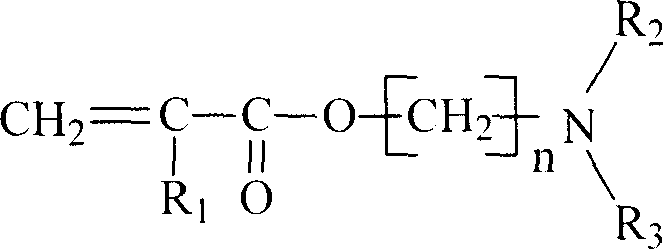

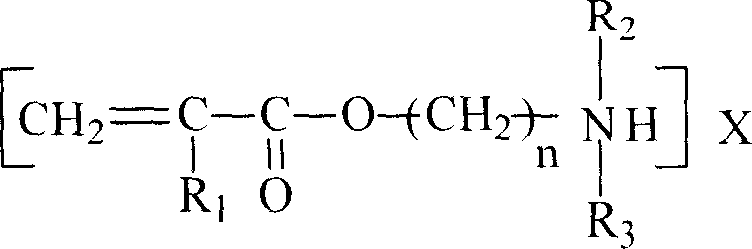

Image

Examples

Embodiment 1~8

[0022] Suspension polymerization is carried out with water as the medium in a reactor equipped with a reflux condenser, an electric stirrer and an electric temperature controller.

[0023] Select vinyl acetate as the second monomer, control the feed weight ratio of acrylonitrile and vinyl acetate to be 92:8, select the required third monomer and determine its feed amount according to the required feed ratio, each embodiment specifically adopts The third monomer and its charging amount are listed in Table 1;

[0024] The total monomer feed concentration is 30%;

[0025] The initiator selected is a redox system composed of an oxidizing agent and a reducing agent, wherein the oxidizing agent is sodium chlorate, and the reducing agent is sodium pyrosulfite. The amount of oxidizing agent added is 0.5wt% based on the total amount of all polymerized monomers, and the amount of reducing agent added is determined by the molar ratio of reducing agent and oxidizing agent being 1.5:1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com