Current down-lead structure of superconducting magnetic energy storage

A current lead, superconducting energy storage technology, applied in superconducting magnets/coils, the usage of superconducting elements, superconducting devices, etc. The effect of thermal paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

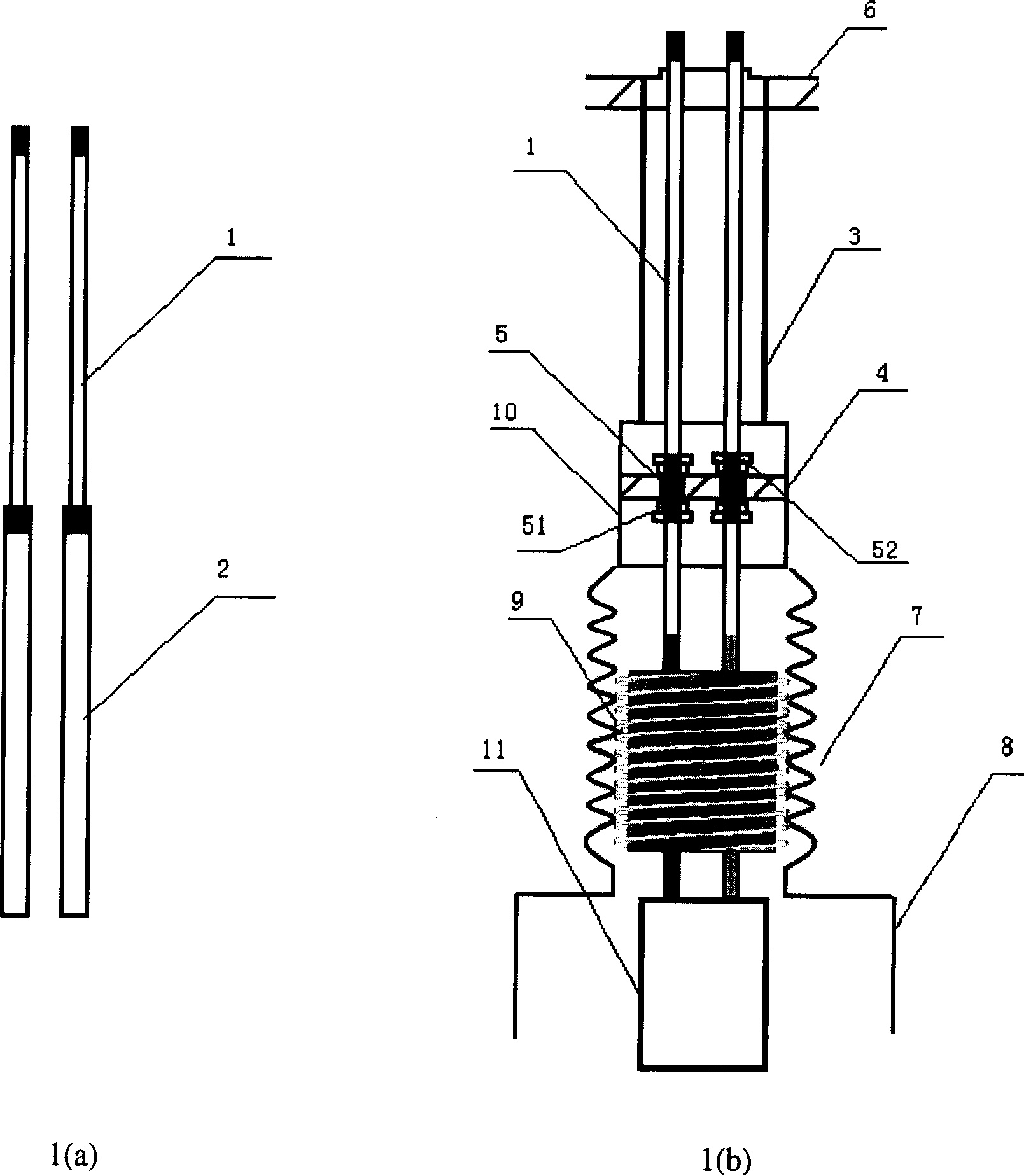

[0029] The present invention proposes a new type of current lead wire structure of a superconducting energy storage magnet. The part near the high temperature end uses a straight rod type copper current lead wire, while the part near the low temperature end is a high temperature superconducting current lead wire with a double helix structure. In the limited space, try to increase the heat transfer path to reduce the heat leakage.

[0030] Another feature of the current lead wire structure of the superconducting energy storage magnet of the present invention is that the joint between the copper lead wire and the heat conduction plate uses insulating and heat-conducting beryllium oxide, and the heat is transferred from the heat conduction plate through the primary cold head of the refrigerator.

[0031] The superconducting energy storage magnet coil needs to work in the liquid helium temperature region of about 4.2K, and it is connected to the power supply at room temperature thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com