Polymeric optical device structures having controlled topographic and refractive index profiles

A technology of optical devices and refractive index, applied in optical components, optics, instruments, etc., can solve problems such as roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

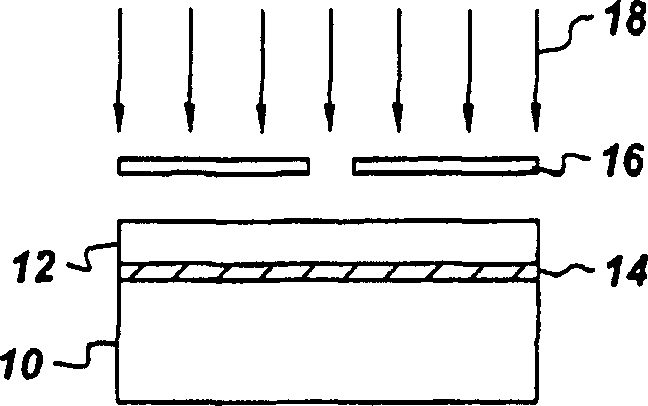

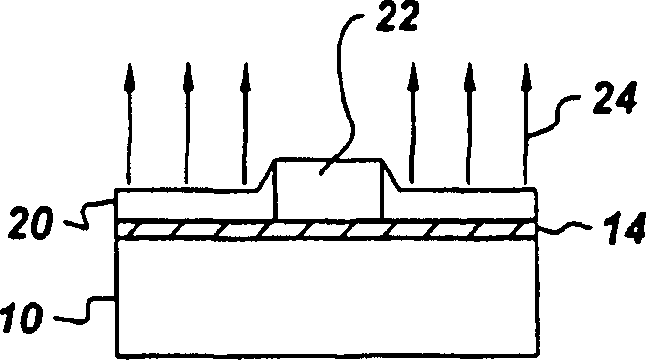

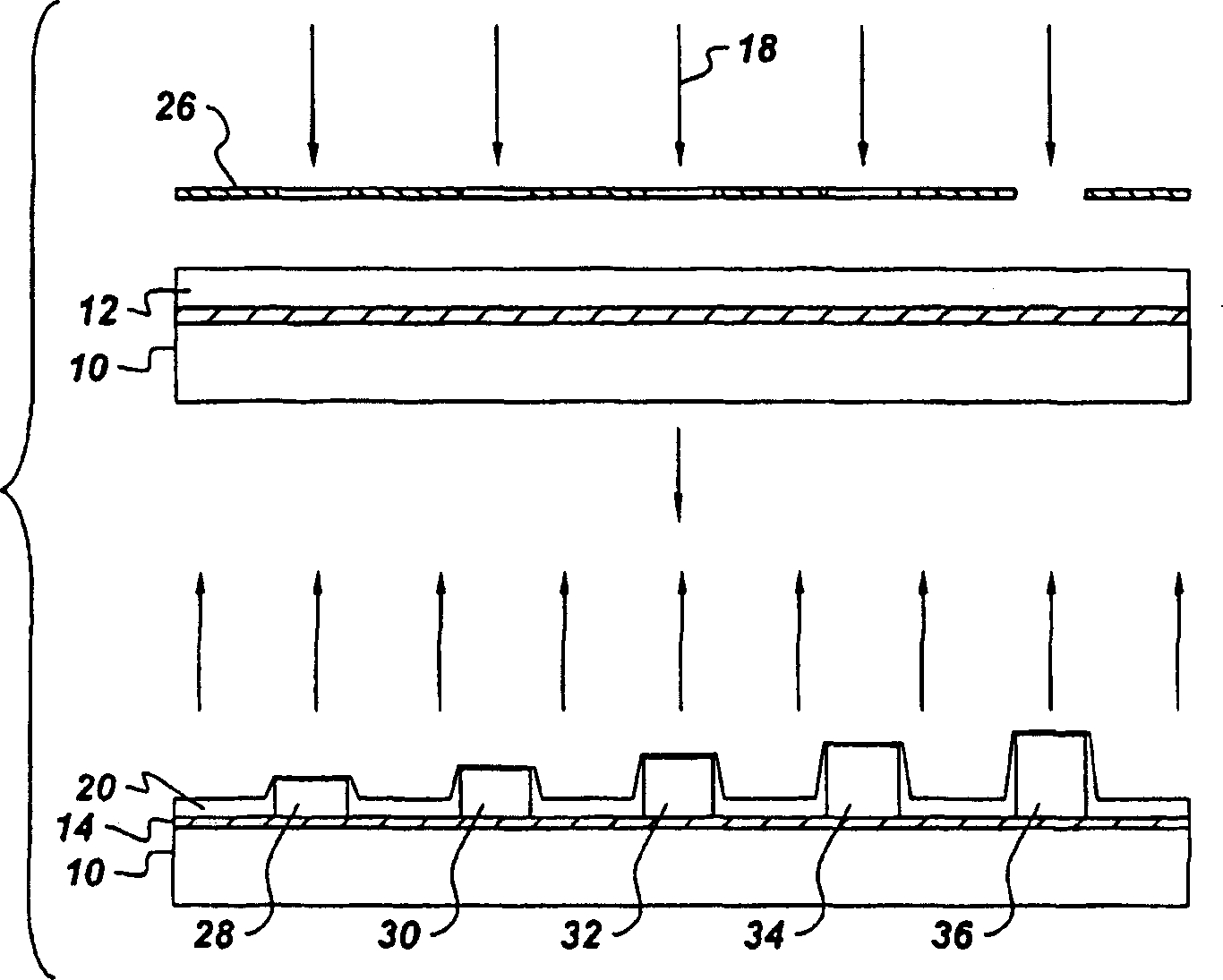

[0050] This example describes the use of UV radiation to prepare TM Surface topography of polymer composites of 9371 polycarbonate (available from Bayer Company) and CY 179.

[0051] Preparation contains about 50 parts by weight of Apec TM A mixture of polycarbonate, about 50 parts by weight of CY 179, 1 part by weight of Cyracure UVI-6976 photocatalyst, 150 parts by weight of anisole and 50 parts by weight of cyclopentanone. A 50 micron thick film was prepared on a glass substrate by spin coating the material and partially curing it at 90°C for 20 minutes to remove the solvent. Image exposure using chrome patterned on a quartz plate and patterned on a polycarbonate / epoxy film. Exposure was performed for 30 seconds using a Karl Suss contact printer. After exposure, the samples were baked on a hot plate at 200°C for 1 hour. Surface profile measurements of the resulting surface topography showed a step of approximately 23 microns between the underlying unexposed film surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com