Superlow antimony alloy for plate of accumulator

An ultra-low antimony battery technology, which is applied in the field of battery plates, can solve the problems of poor deep cycle capability, less battery maintenance, and high water loss rate, and achieve the effects of improving corrosion resistance, improving overall performance, and reducing water loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The manufacturing process of the ultra-low antimony alloy for battery pole plate of the present invention comprises the following steps:

[0014] 1. First make Cu-Sb alloy, Cu: 20%~24%; Sb: 76%~80%; light heat until Sb melts to 700°C, add Cu to the end, and keep for 10 minutes;

[0015] 2. Make Sb-As alloy again: Sb: 62%-72%; As: 28%-38%; first heat Sb to 700°C, add As in stages, each time to the end, about 10 minutes to reach the formula quantity;

[0016] 3. Making Cu-Sb-As-S-Sn-Pb. First heat Pb to 680°C, add Cu-Sb alloy, As-Sb alloy, Sn, and then add S to complete.

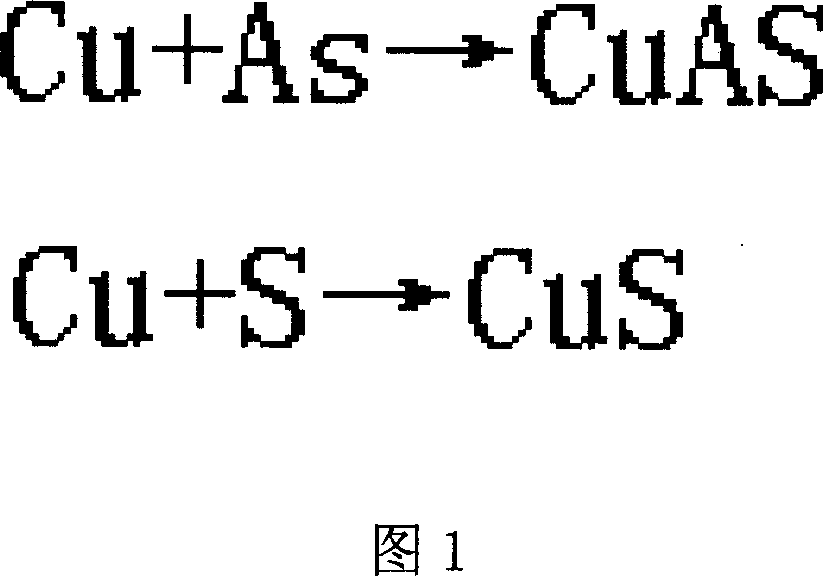

[0017] As shown in Figure 1, it is a partial reaction equation during the production process of the ultra-low antimony alloy used for the battery pole plate of the present invention. The specific configuration method includes the following steps:

[0018] 1. Add 9.2kg of electrolytic antimony to the electric furnace and heat and melt it. When it reaches 700℃, add 0.6kg of copper shavings to form an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com