Optical fiber grating displacement sensor

A technology of displacement sensor and optical fiber grating, which is applied in the field of sensing, can solve the problems of poor long-term stability and susceptibility to electromagnetic interference, etc., and achieve the effect of convenient construction and installation, low cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

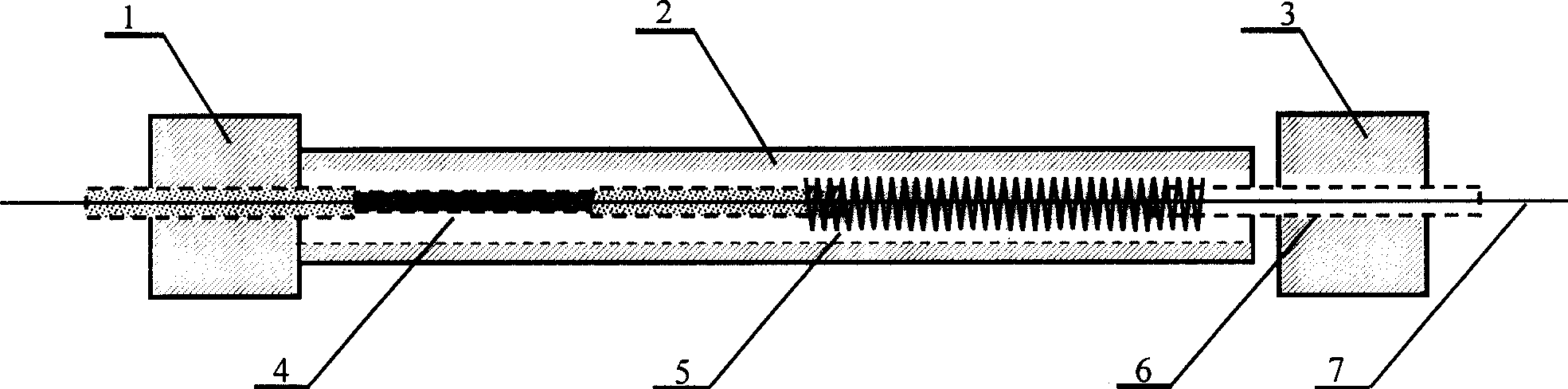

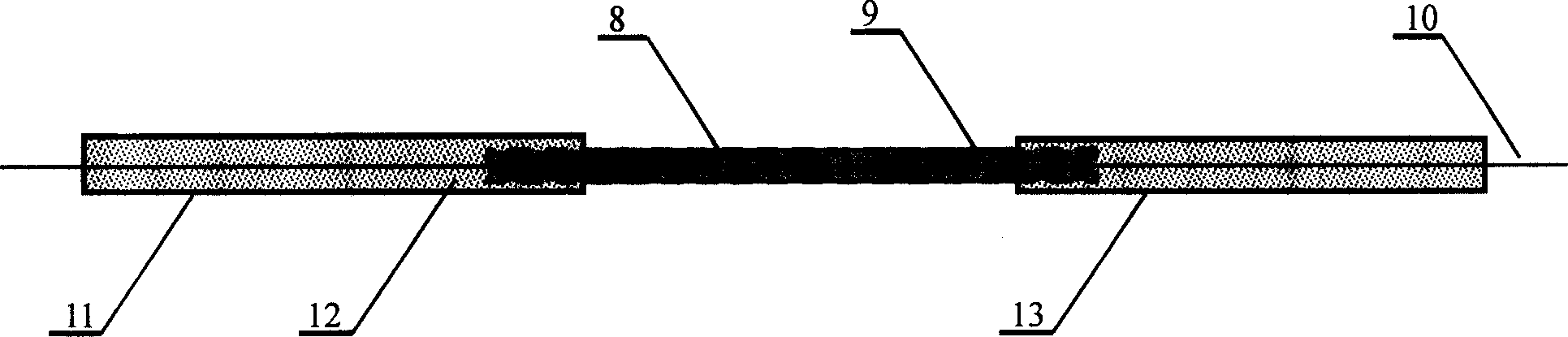

[0012] The fiber grating displacement sensor that the present invention proposes is shown in the attachment figure 1 As shown, the cross-sectional schematic diagram of the fiber grating strain sensor involved is shown in the attached figure 2 shown.

[0013] The specific method of fiber grating packaging is to first use a fiber coating machine to coat the fiber grating 8, then place it in a 0.5mm steel pipe 9, and use a precision fiber adjustment frame to adjust the position of the fiber grating 8, so that the fiber grating 8 is in the Then pour epoxy resin glue 12 into the central part, respectively install 1.2mm steel pipe 11 and 1.2mm steel pipe 13 on both sides of 0.5mm steel pipe 9, also pour epoxy resin glue 12, and complete the packaging process after the glue is cured.

[0014] The specific method of assembling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com