Double-purpose and coal-saving boiler with hot air heat and water supply

A hot air heating and boiler technology, applied in the field of boilers, can solve the problems of poor heat exchange effect, exhaust gas polluting the atmosphere, wasting energy, etc., and achieve the effects of preventing indoor drying, saving coal, and simple heating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

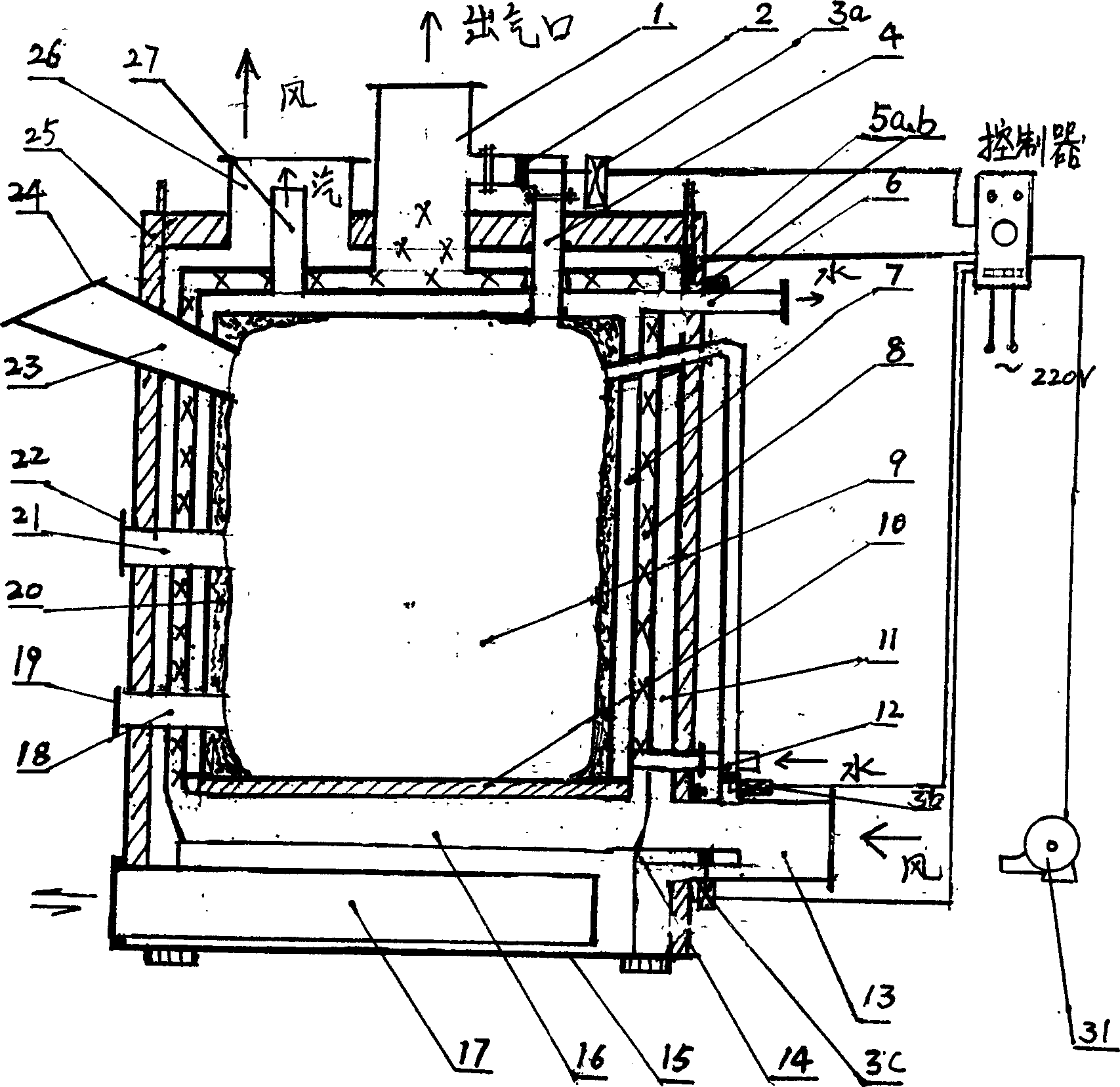

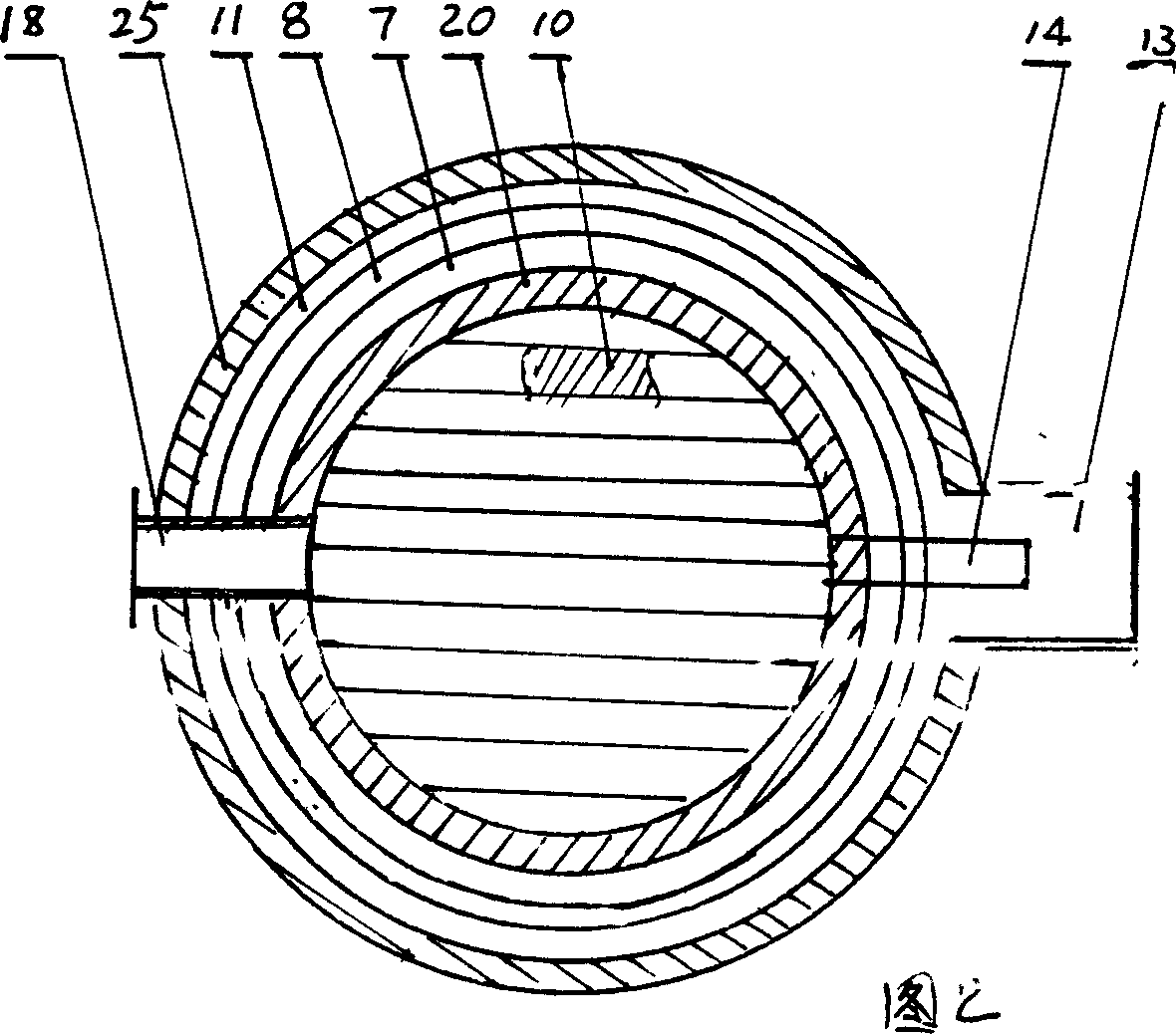

[0012] figure 1 ,figure 2, image 3 , Figure 4 It is a way of concrete implementation. Describe its construction according to the manufacturing process.

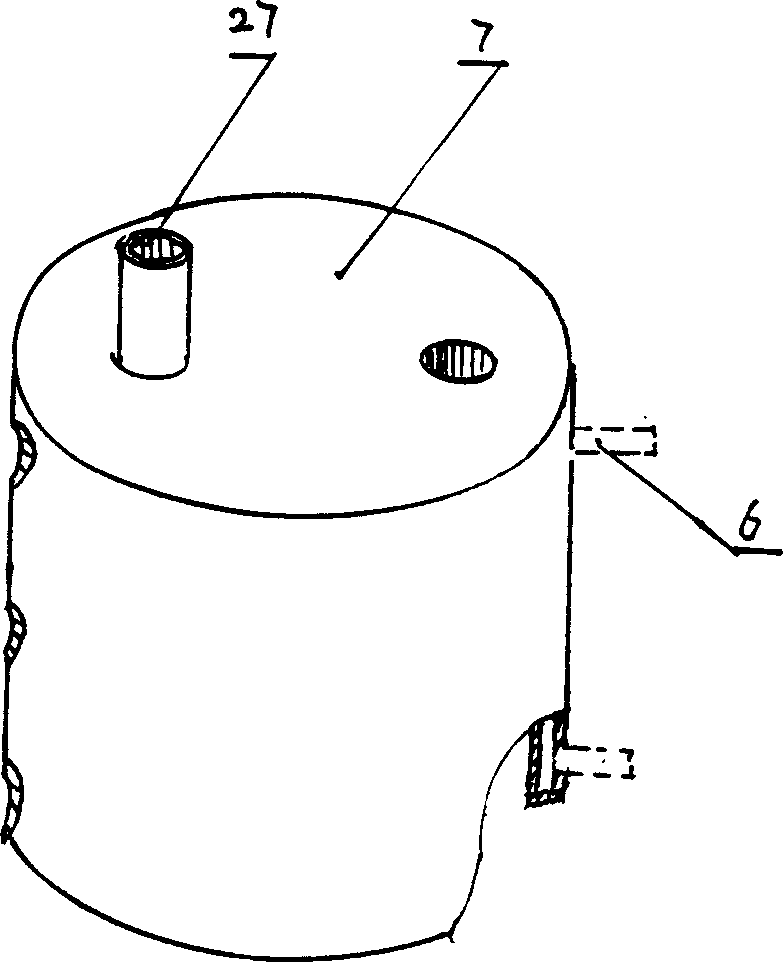

[0013] 1. Process the inner water jacket 7. The inner water jacket 7 is welded by steel plates such as image 3 The double-layer closed cylinder shown in the figure has holes for furnace doors 18, 21, 23, holes for exhaust pipe 4, holes for blasting branch pipe 12 in the air-making chamber, and steam outlet pipe 27, The hole of water outlet pipe 6 and exhaust pipe.

[0014] Second, processing the outer hot air jacket 11. Outer hot air cover 11 is welded into such as by steel plate Figure 4 As shown in the double-layer closed cylinder, its inner diameter is greater than the outer diameter of the inner water jacket, and the two cylinders can form a flame burning space after they are put together; all holes corresponding to the inner water jacket 7 must be processed on the cylinder; except In addition, an exhaust pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com