Process and flow for recovering hydrocarbon component from hydrocarbon containing gas

A hydrocarbon gas and hydrocarbon technology, applied in the field of recovery of hydrocarbon components, can solve problems that restrict the market promotion and application of oil and gas recovery projects, large processing capacity, and large installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

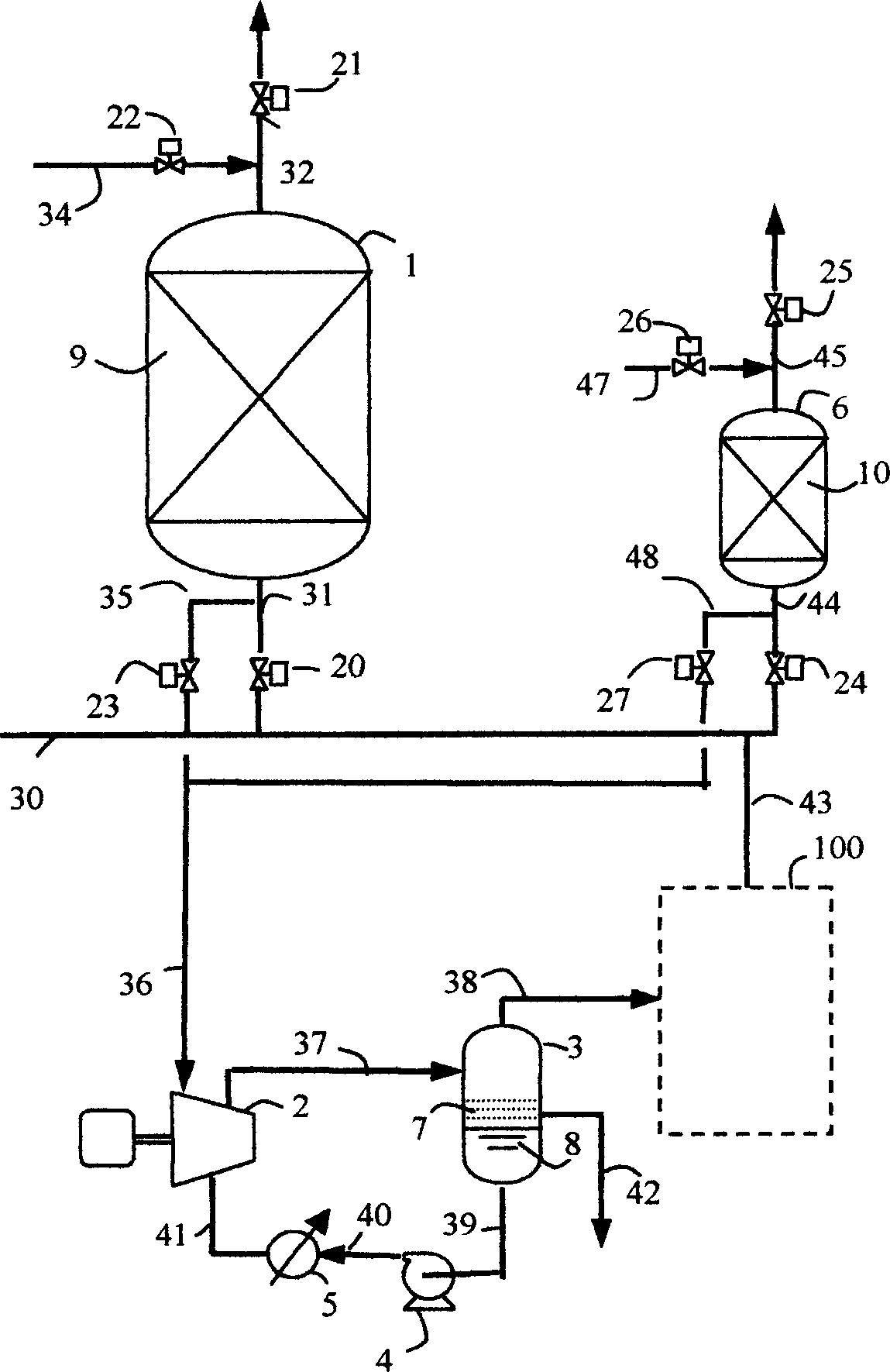

[0030] exist figure 1In the flow process shown, the first adsorption tank (1) and the second adsorption tank (6) are two adsorption devices filled with solid adsorbent (activated carbon) bed (9) and bed (10) inside, containing hydrocarbon One end of the inlet pipeline (30) where the gas-like gas enters the oil vapor recovery device is connected to the discharge source (not shown in the figure), and the other end is connected to the first adsorption tank (1) and the second adsorption tank through the pipeline (31) and the pipeline (44) respectively. The entrance of (6) is connected. One end of the pipeline (32) communicates with the outlet of the first adsorption tank (1), and the other end communicates with the atmosphere. One end of the pipeline (45) communicates with the outlet of the second adsorption tank (6), and the other end communicates with the atmosphere. On the inlet pipeline (31), pipeline (44) and outlet pipeline (32), pipeline (45) of the adsorption tank, on-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com