Equipment and method for washing prodn. of nitrobenzene

A production device and technology of nitrobenzene, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of increasing equipment investment and operating costs, small operating flexibility, and large water consumption, etc., to achieve Increase effective production time, stable operation, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

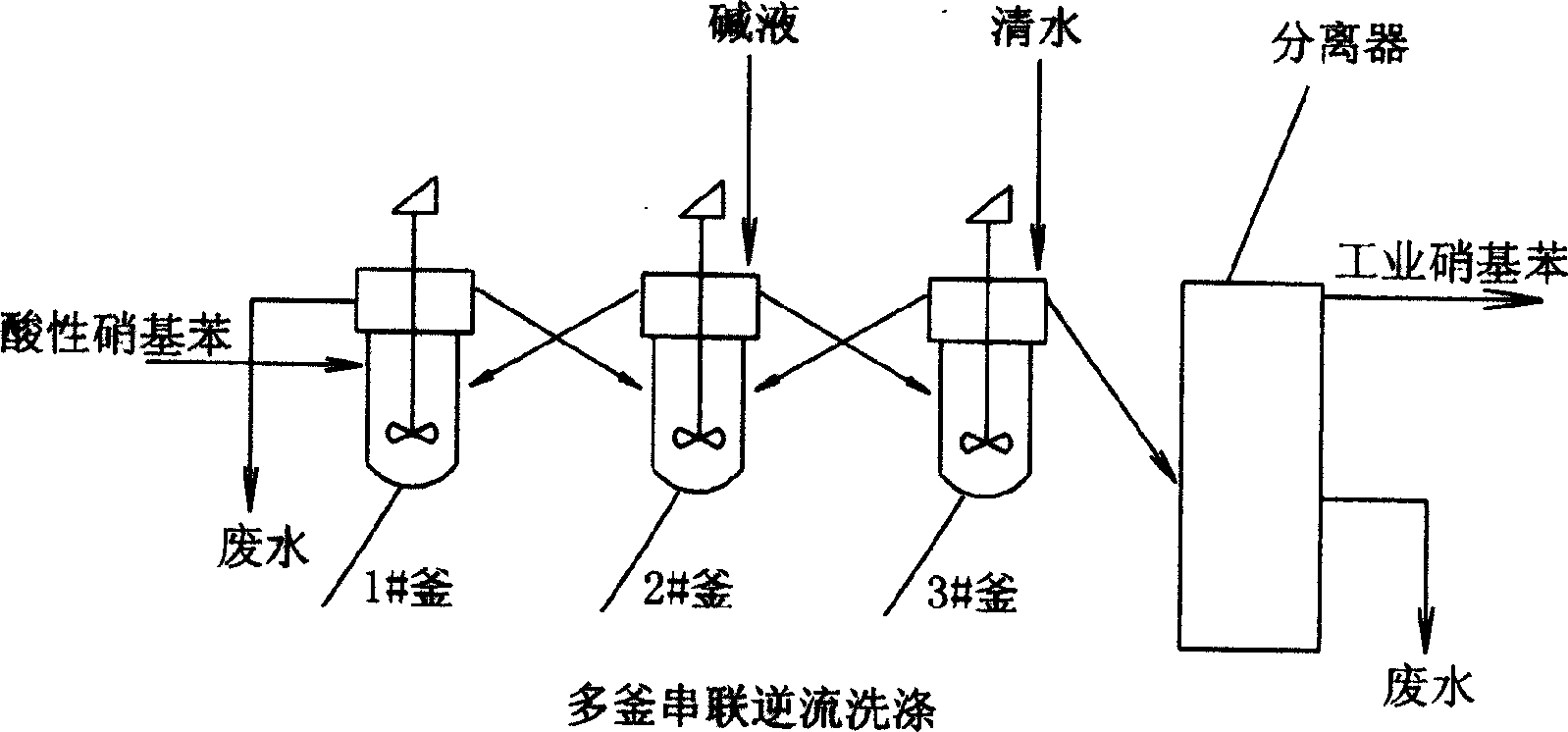

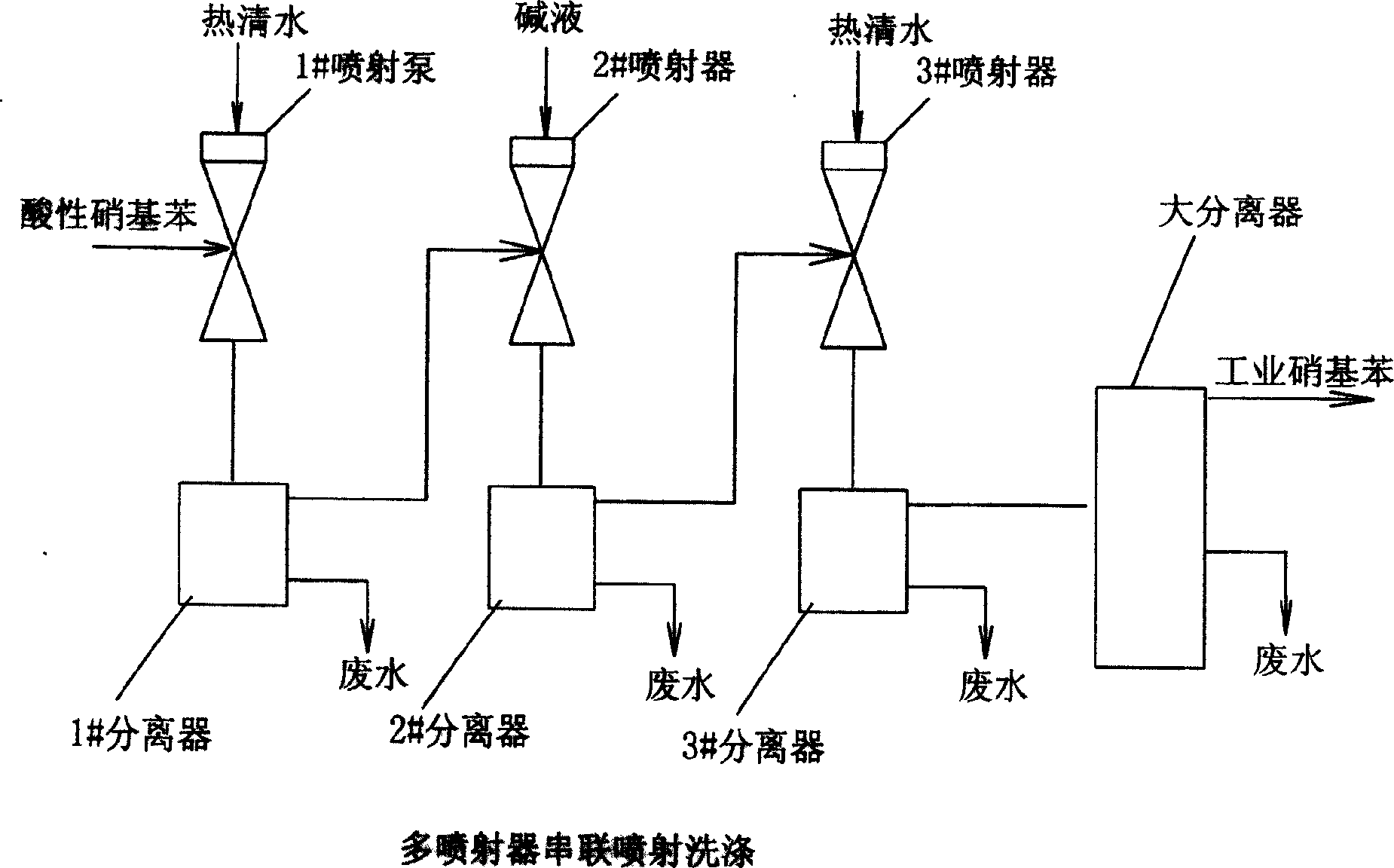

Problems solved by technology

Method used

Image

Examples

Embodiment 1

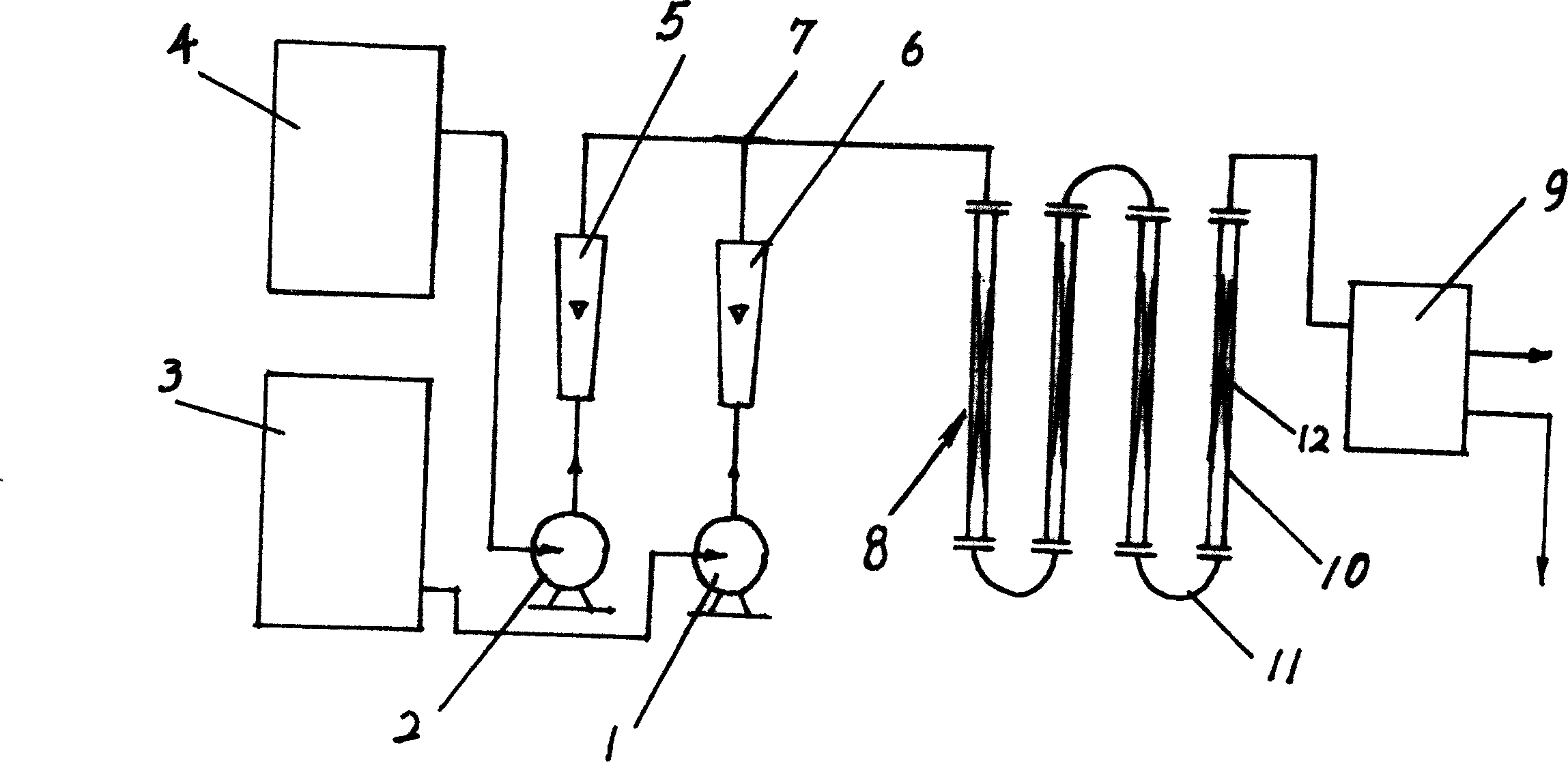

[0026] Nitrobenzene washing production device, including nitration mixed liquid separator 3, lye tank 4, lye delivery pump 2, crude nitrobenzene delivery pump 1, crude nitrobenzene flowmeter 5, lye flowmeter 6, tee 7. Crude nitrobenzene scrubber 8. Washing waste water separator 9. The crude nitrobenzene scrubber 8 is composed of four short pipes 10 connected by connecting pipes 11 . Every short pipe 10 is 4m long and has a diameter of 120mm.

[0027] Specific installation method: the crude nitrobenzene outlet of the nitration mixed liquid separator 3 is connected with the crude nitrobenzene delivery pump 1 inlet through a pipeline, the lye outlet of the lye tank 4 is connected with the lye delivery pump 2 inlet through a pipeline, and the crude nitrobenzene Base benzene delivery pump 1 and lye delivery pump 2 outlet pipelines are respectively equipped with thick nitrobenzene flowmeter 5 and lye flowmeter 6 with display, and are connected with three-way pipe 7, and another int...

Embodiment 2

[0029] The structure of the second embodiment is basically the same as that of the first embodiment, except that: the short pipe 10 of the crude nitrobenzene scrubber 8 is provided with a built-in component 12 .

Embodiment 3

[0031] The production method of washing nitrobenzene comprises storing the equivalent alkali liquor used in the neutralization reaction and the dephenolization reaction in the alkali liquor tank 4, and the nitrification mixed liquor obtained by the nitrification reaction enters the nitrification mixed liquor separator 3, and through this separation operation, the The waste acid contained in the nitration mixture should be as little as possible to reduce the consumption of washing alkali. The pre-separation of waste acid adopts sedimentation separation or hydrocyclone separation. After the nitration waste acid is separated, the crude nitrobenzene to be washed is obtained. The lye is pumped out through the lye delivery pump 2, enters the pipeline, and enters the tee 7 after passing through the lye flow meter 6 with a display, and the crude nitrobenzene after the nitration waste acid is separated is transferred from The nitrification mixed liquid separator 3 is pumped into the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com