Armoured material and its shaping method

A technology of bulletproof and bulletproof layer, which is applied to the structure of the armor plate, etc., to achieve the effect of good curing effect and uniform resin penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

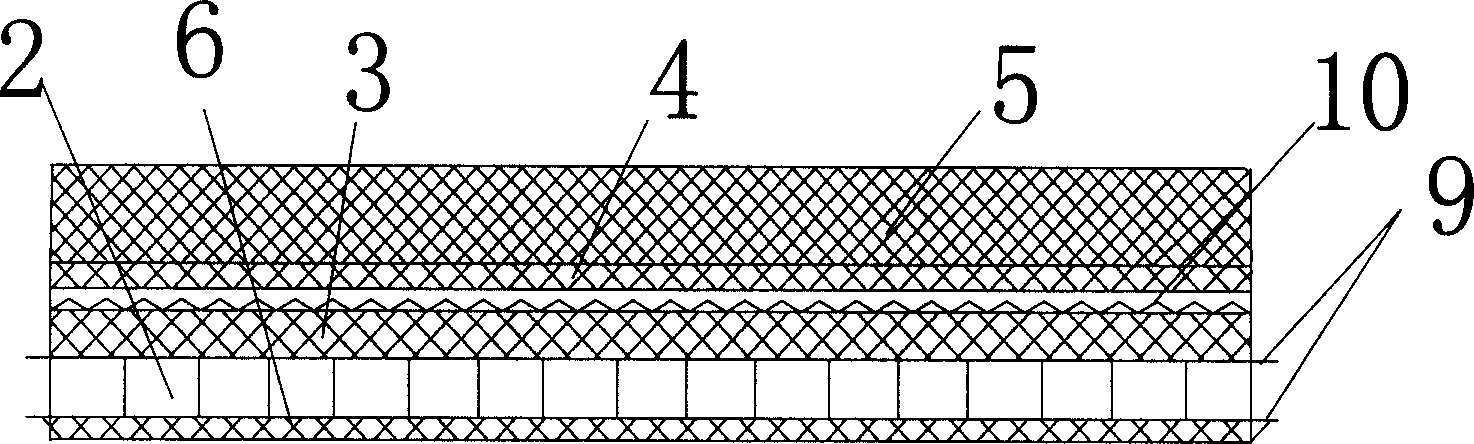

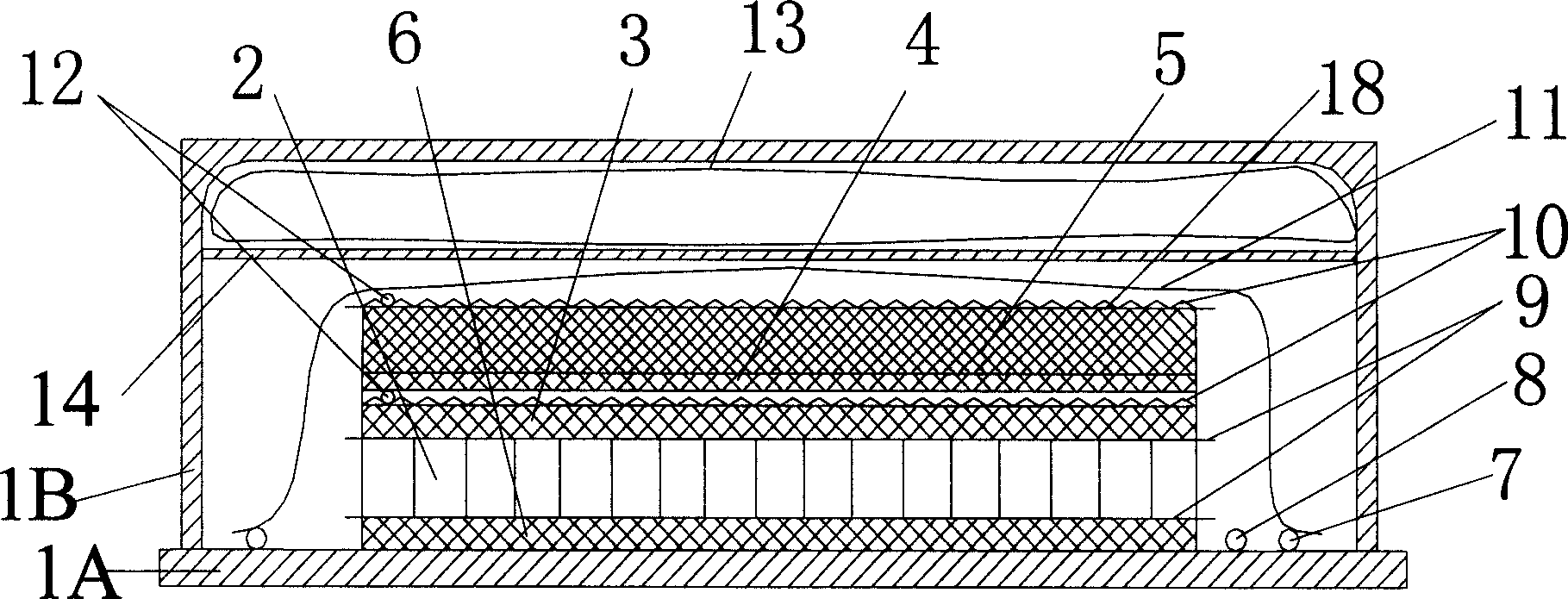

[0045] Embodiment 1: Take a flat mold and coat the surface with a 0.01mm thick release agent. First, a 2mm thick surface durable layer is prepared by a conventional vacuum-assisted molding process, and one side is polished to remove residues; Take a number of ceramic sheets with a size of 50mm×50mm×10mm and a rough surface. Rinse them with acetone. Also bonded with an adhesive, the thickness of the ceramic layer is 10mm. After bonding, brush a layer of adhesive on the ceramic surface. The adhesive is epoxy-polyamide adhesive, and a rigid backplane layer is laid. The rigid backplane layer is made of 27 layers of carbon fiber cloth, and then a layer of high-permeability medium layer is laid in turn. , As the composite material of the isolation layer, the composite material is also prepared in advance by vacuum assisted forming process, and then the bulletproof functional layer is laid. The bulletproof functional layer is formed by overlapping 50 layers of aramid fiber cloth, and...

Embodiment 2

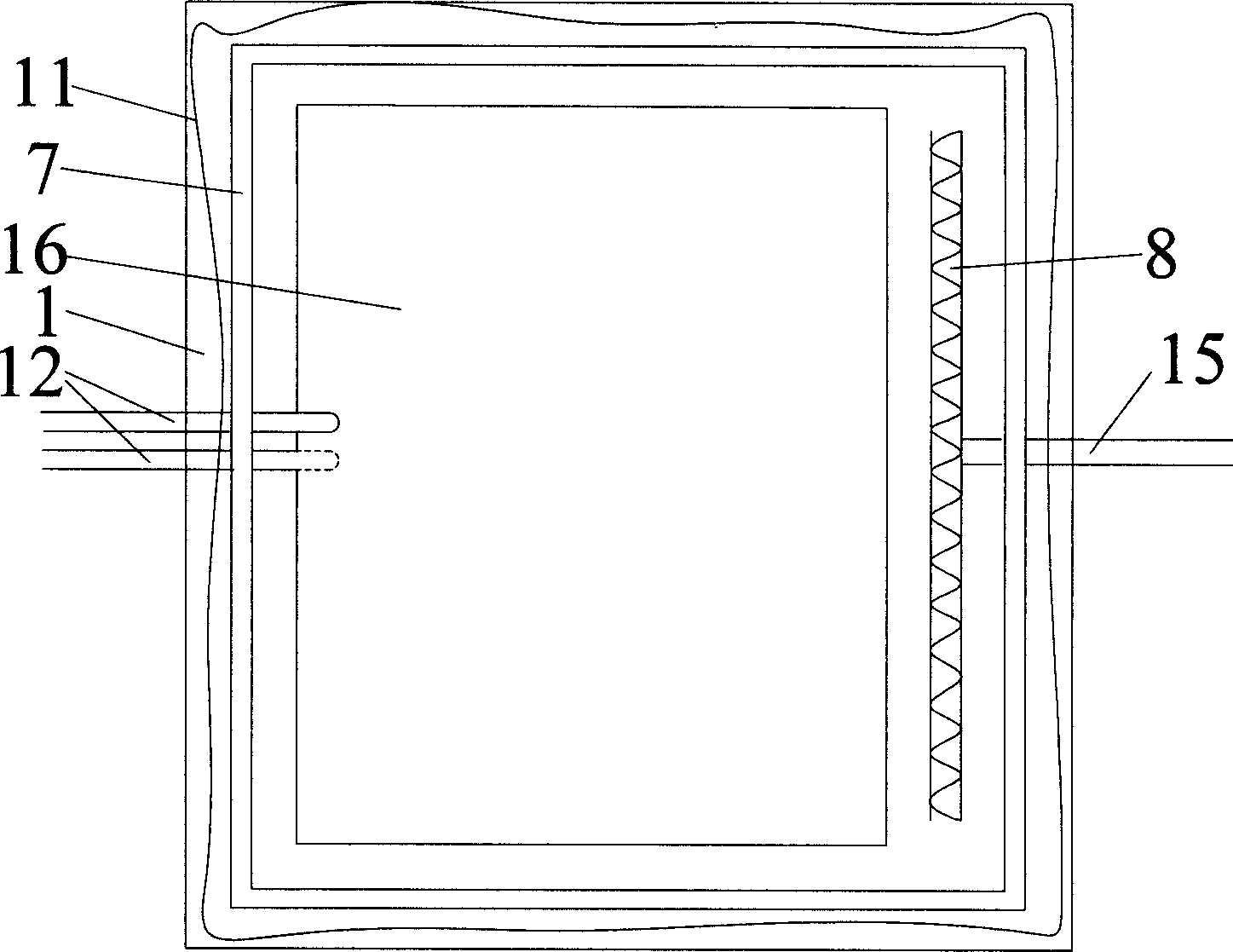

[0046] Embodiment 2: Take a special-shaped mold, coat it with a 0.03mm thick release agent, and then lay a rigid backplane layer, a high-permeability medium layer, an isolation layer, a bulletproof functional layer, and a release cloth in sequence from bottom to top A layer of high-permeability medium layer is laid on the upper surface of the release cloth. The rigid backsheet layer 3 is made of overlapping layers of 17 layers of high-strength glass fiber cloth; the isolation layer 4 is made of conventional rubber sheets, and the bulletproof functional layer is made of 30 layers of PBO. The fiber cloth is laid overlappingly; a layer of release cloth and a high-permeability medium layer are laid on it, and a spiral tube vacuum line is laid on the side of the multi-layer material laid above, and there is a glue injection on the same side of the high-permeability medium layer Put a ring of sealant on the periphery of the special-shaped mold, and cover the vacuum bag film. Except f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com