Jib bed density distribution detector

A bed density and detection device technology is applied in the field of a jig washing bed density distribution detection device and a device for real-time detection of material density. Separation accuracy, reduction of material mismatch rate, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

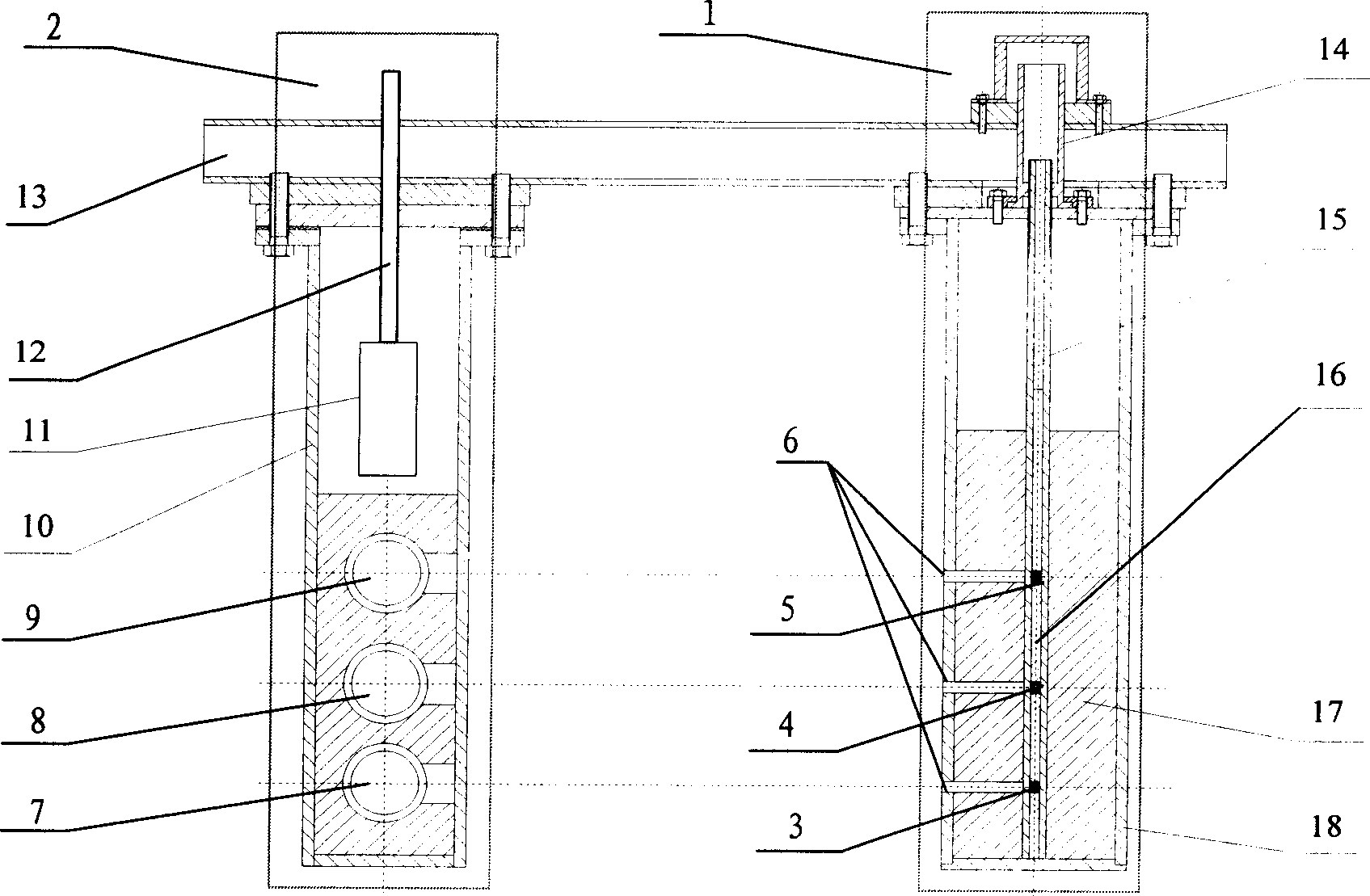

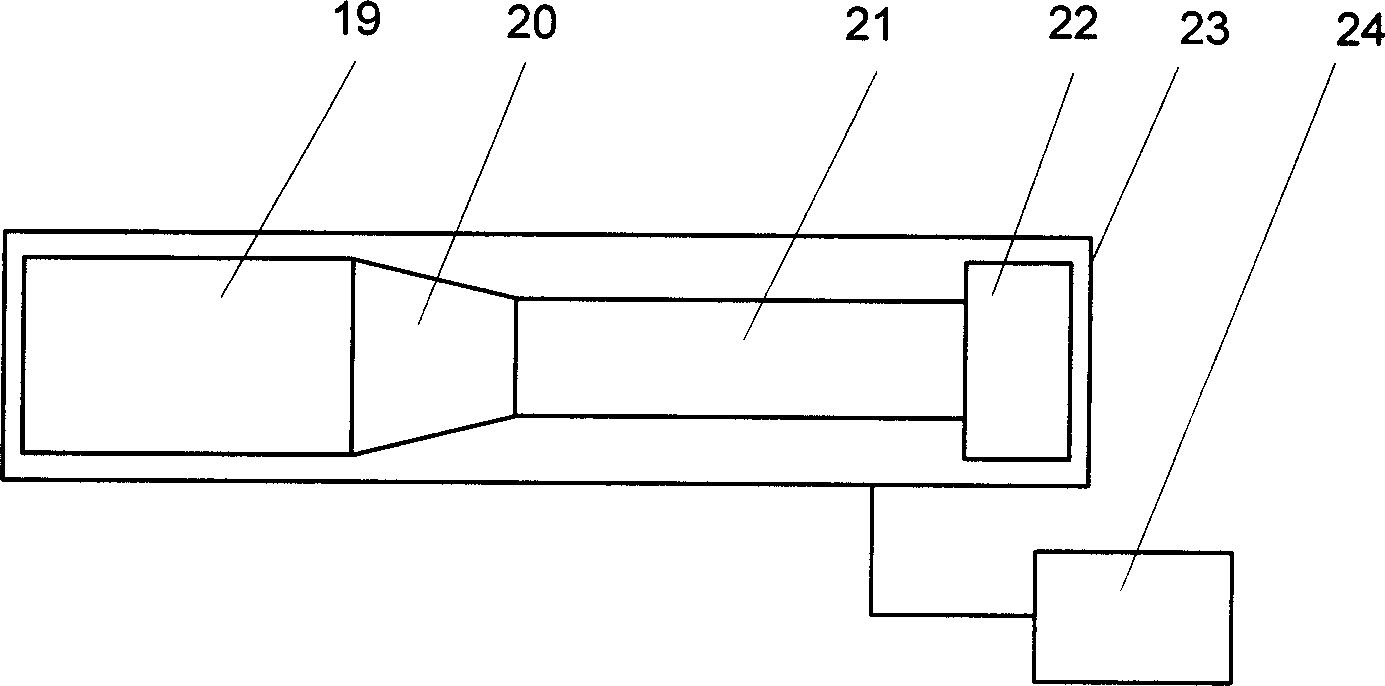

[0021] Embodiment 1: The device for detecting the material density of the jig multi-source gamma-ray bed is as follows: Figure 5 Placed in the jig machine bed, the distance between the gamma-ray radiation source assembly 1 and the photodetector assembly 2 is 600mm, the distance between the bottom gamma-ray radiation source 3 and the sieve plate of the jig machine is 90mm, and the bottom gamma-ray radiation source 3 and the middle layer gamma-ray The distance between the radiation source 4 is 100 mm, and the distance between the middle layer γ-ray radiation source 4 and the upper layer γ-ray radiation source 5 is 90 mm. After the photodetectors 7, 8, and 9 corresponding to the above-mentioned γ-ray radiation sources receive the incident particles attenuated by the coal seam, they are multiplied and amplified by the photomultiplier tube 21 for multiple times, and finally the photodetector assembly 2 figure 2 The subsequent circuit shown outputs an electrical pulse signal. The...

Embodiment approach 2

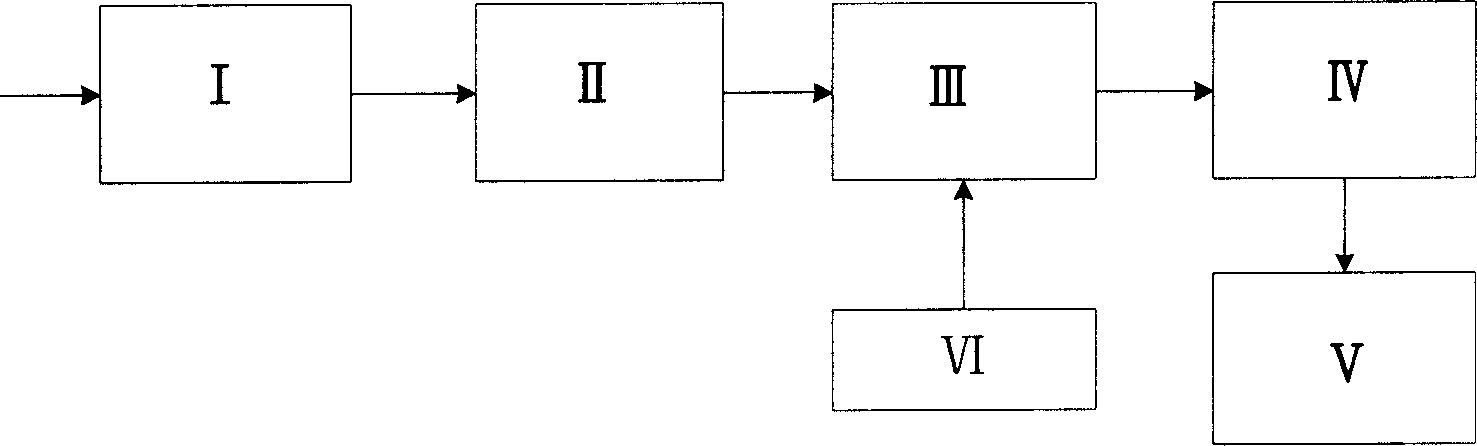

[0022] Embodiment 2: counting time by Figure 4 Controlled by the gate control signal shown: Calculate the bed density value of the jig machine in the loosening period of the upper, middle and lower three horizontal positions from the count value during the low level period of D1. Others are the same as Embodiment 1.

Embodiment approach 3

[0023] Embodiment 3: counting time by Figure 4 The gating signal shown is used to control: count at the same time during the low level period of D1 and D2, and calculate the bed density value of the loose period and the compact period of the jig in the upper, middle and lower three horizontal positions. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com