Multifunctional cold aerosol fire extinguishing agent and its preparation method

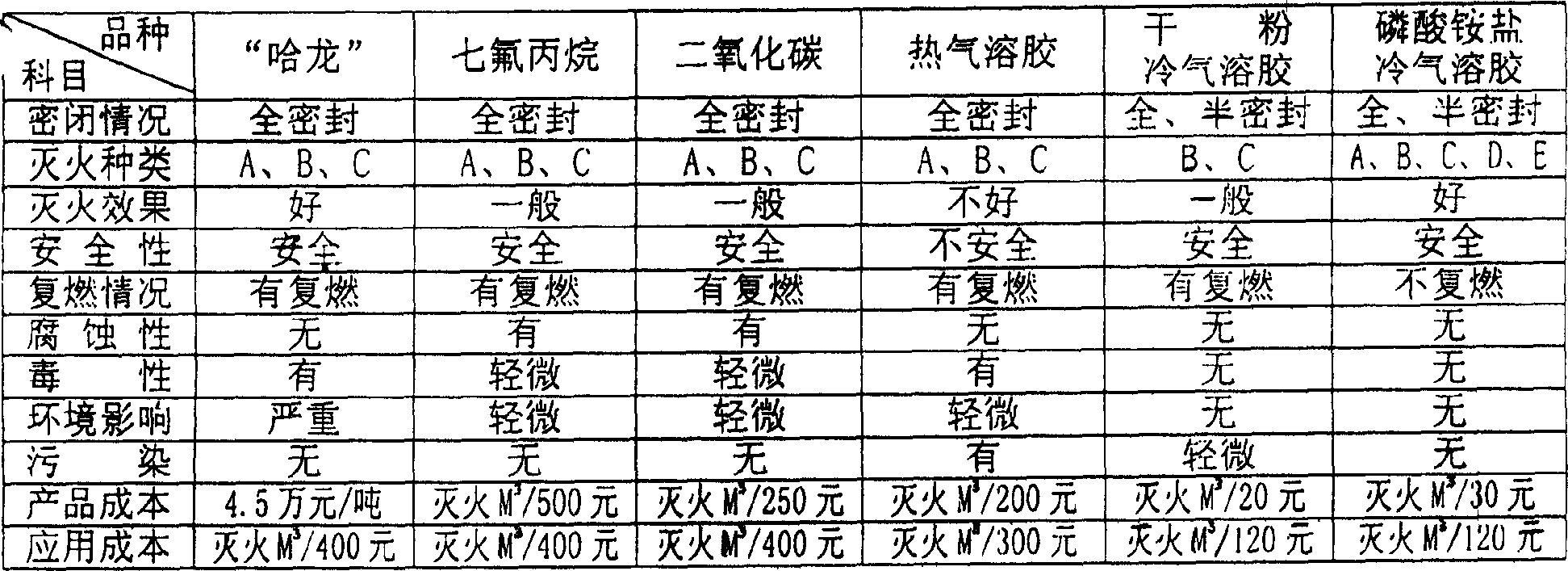

A technology of cold aerosol and fire extinguishing agent, which is applied in the direction of fire prevention equipment, etc., can solve the problems of limited application conditions, high production cost and high application cost, and achieve the effect of low production cost, low application cost and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare 50 type (MAP50%) cold aerosol multifunctional fire extinguishing agent according to the following raw material weight proportions and steps:

[0024] Get 500kg of ordinary ammonium phosphate dry powder, 10kg of mica, 20kg of ammonium sulfate, 20kg of white clay, 400kg of calcium carbonate, 20kg of sodium chloride, and 30kg of white carbon black, mix and pulverize to below 10 microns, add 5kg of silicone oil, 5kg of kerosene (solvent oil), Mix at constant temperature and reduce the water content to below 0.3%.

Embodiment 2

[0026] Prepare 25 (MAP25%) type cold aerosol multifunctional fire extinguishing agent according to the following raw material weight proportions and steps:

[0027] Take 300kg of wet-process monoammonium phosphate powder, 30kg of mica, 100kg of ammonium sulfate, 30kg of clay, 400kg of calcium carbonate, 40kg of sodium chloride, and 100kg of white carbon black, mix and pulverize them to less than 10 microns, add 15kg of silicone oil, and 20kg of gasoline (solvent oil) , Mix at constant temperature and reduce the water content to below 0.3%.

Embodiment 3

[0029] Prepare 85 type (MAP85%) cold aerosol multifunctional fire extinguishing agent according to the following raw material weight proportions and steps:

[0030] Get 850kg of ordinary ammonium phosphate dry powder, 15kg of mica, 20kg of ammonium sulfate, 10kg of white clay, 55Kg of calcium carbonate, 20kg of sodium chloride, and 30kg of white carbon black, mix and pulverize to below 10 microns, add 5kg of silicone oil, 15kg of kerosene (solvent oil), Mix at constant temperature and reduce the water content to below 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com