Distributed microstructure optical fiber gas sensing system and sensing method

A technology of micro-structured optical fiber and sensing system, which is applied in the fields of analyzing materials, measuring color/spectral characteristics, and analyzing materials through optical means. and permeable gas absorption chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

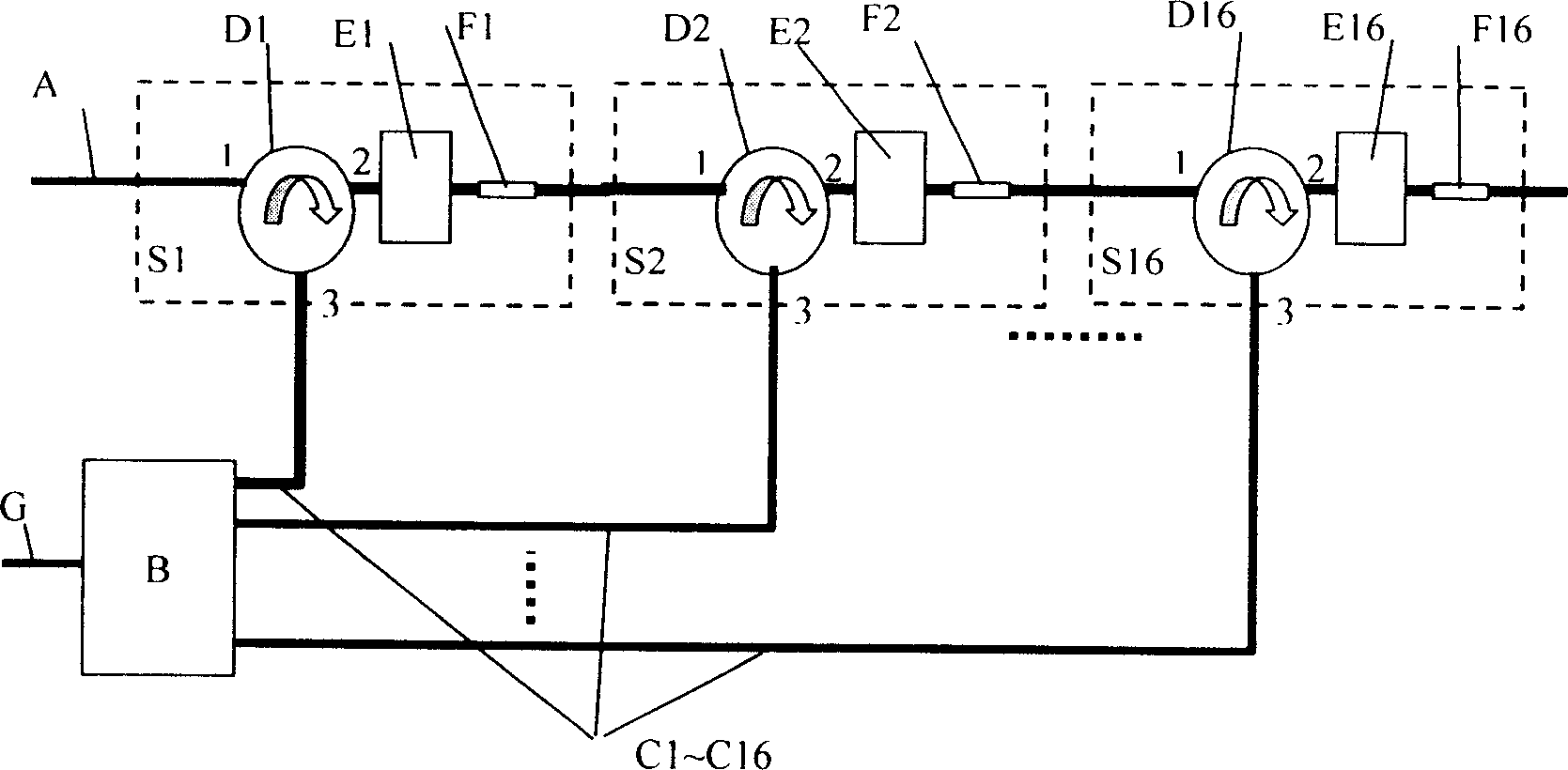

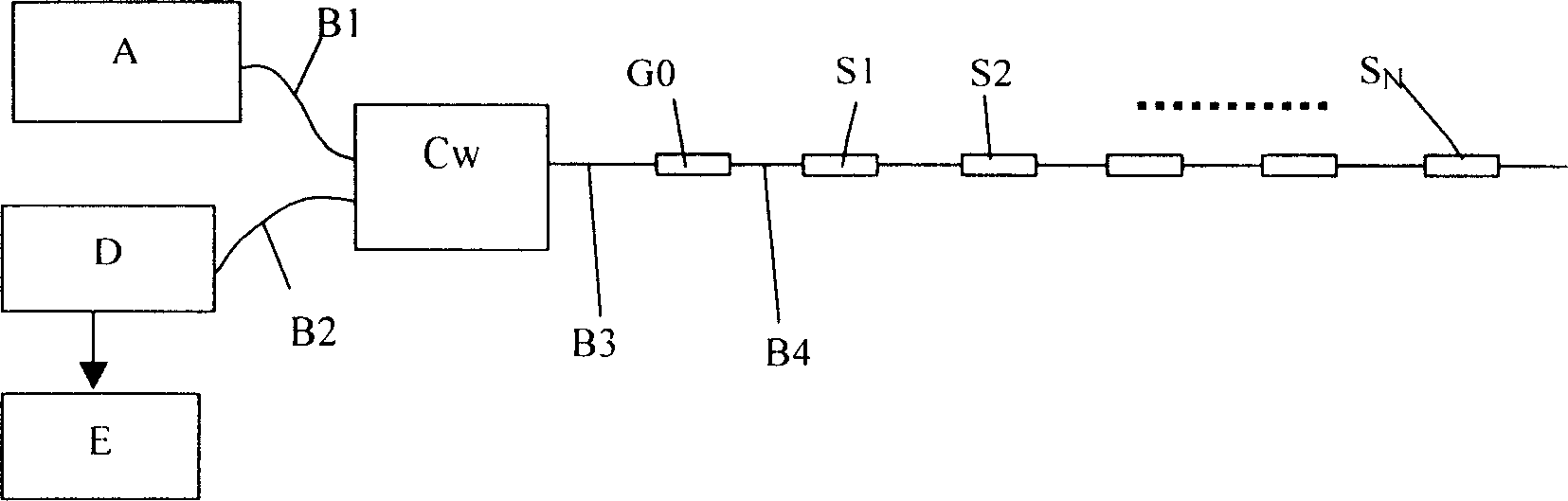

[0059] Further illustrate the present invention below in conjunction with accompanying drawing:

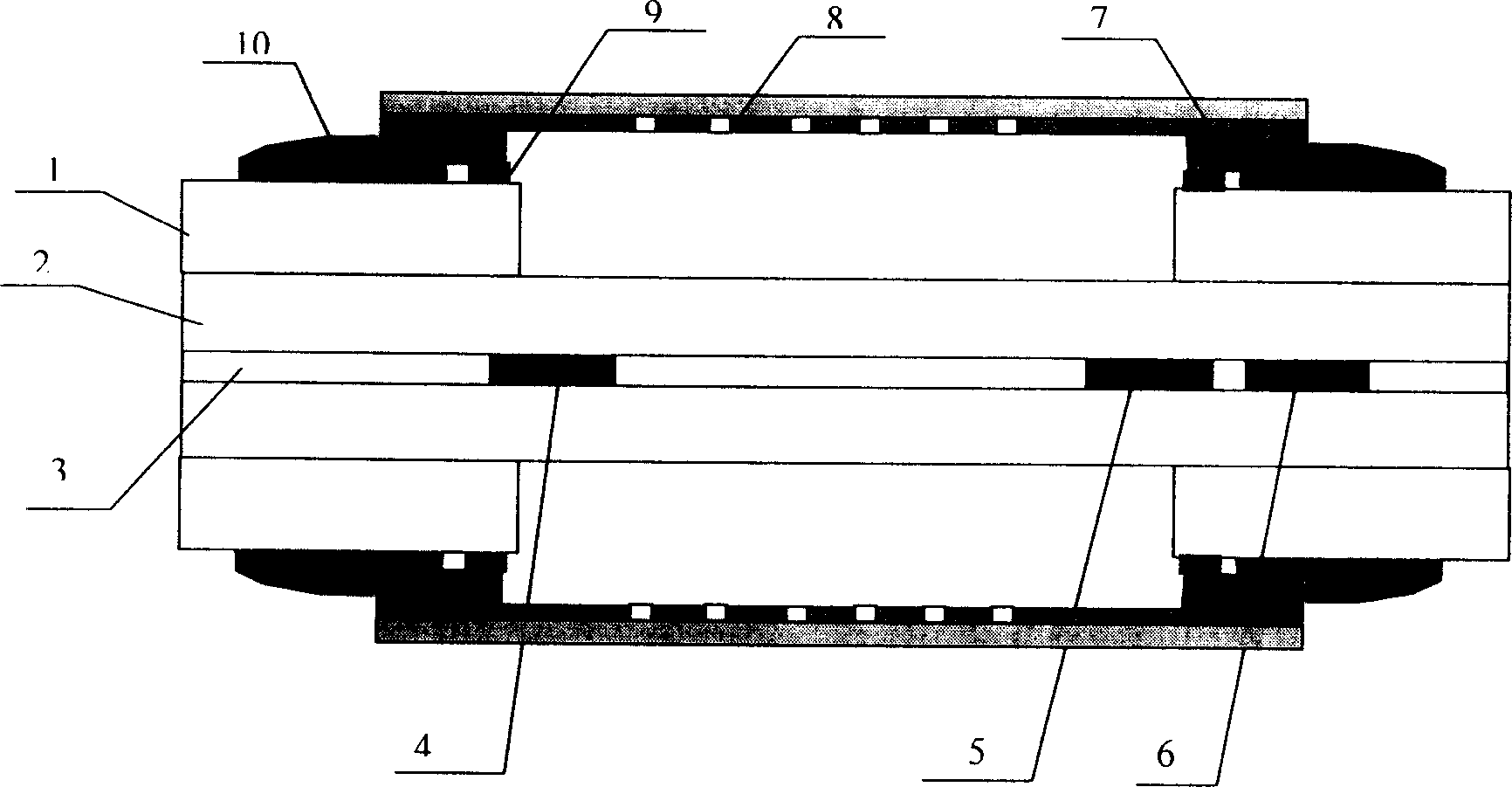

[0060] see figure 2 The structure of the SLR microstructure fiber gas sensor in this sensing system includes: fiber coating 1, fiber cladding 2, fiber core 3, long-period fiber grating LPFG14, long-period fiber grating LPFG25, short-period fiber grating 6 , protective cover 7, dust filter thin layer 8, curing glue 9, transition buffer cover 10. Among them, the optical fiber material is quartz, and two long-period fiber gratings with a length of about 20 mm are arranged on a section of optical fiber that has removed the plastic protective coating; the two long-period fiber gratings are 10 cm apart, and their coupling center wavelengths are both 1160 nm. Its 3dB bandwidth is 10nm, the coupling efficiency at the central wavelength is 99.7%, and the wavelength bandwidth at which the coupling efficiency is greater than 99% is 3.5nm; there is a short-period fiber grating outside the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com