Electric deionisation method and apparatus for producing superpure water using bipolar membrane

A technology of electrodeionization and bipolar membranes, applied in separation methods, ion exchange water/sewage treatment, general water supply saving, etc., can solve the problem that the silicon removal rate is difficult to reach 99.9%, and the removal efficiency of weakly acidic anion impurities is not high , equipment investment increase and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] The present invention has various embodiments, and the implementation of the present invention will be described below with reference to the accompanying drawings.

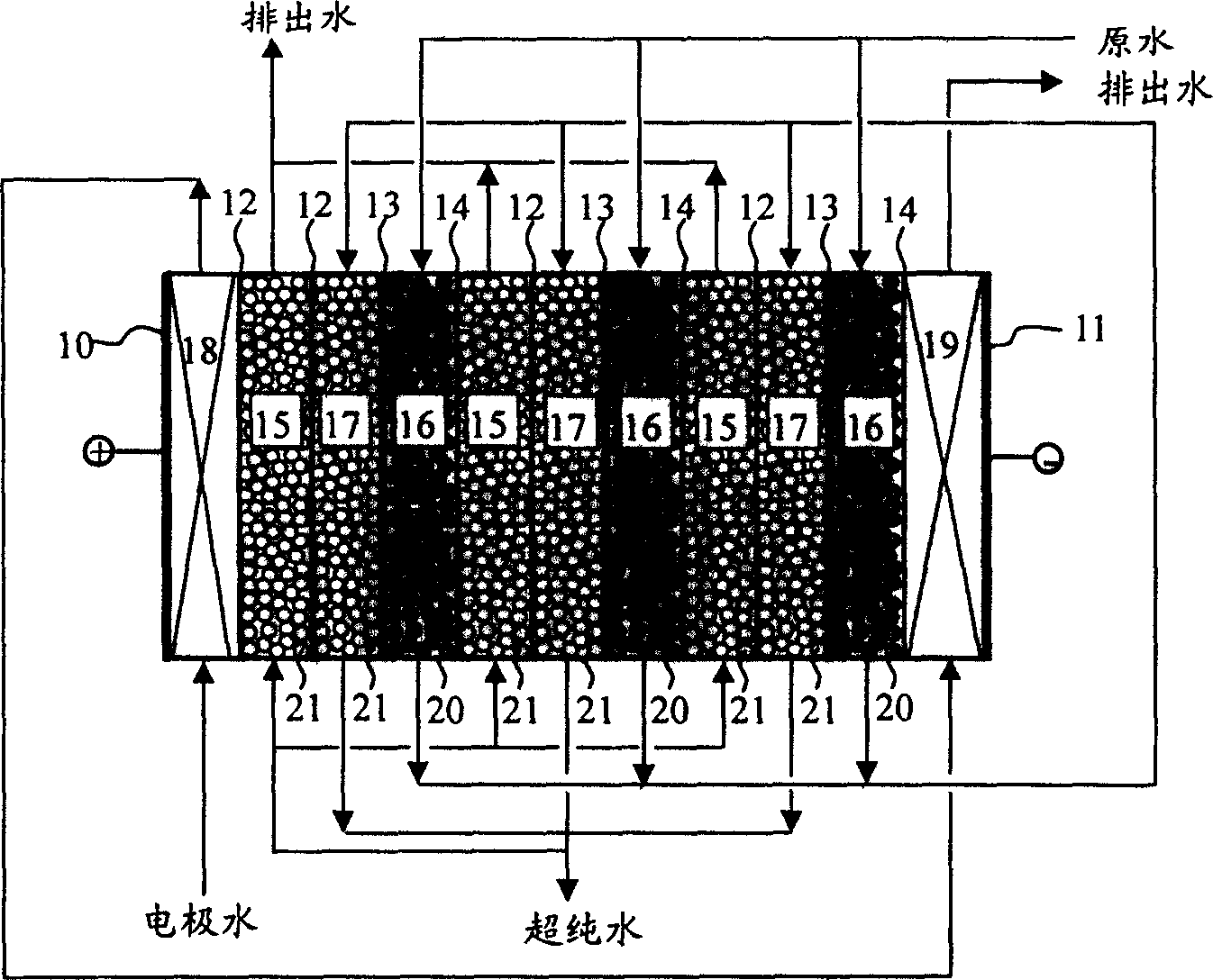

[0018] figure 2 It is a schematic diagram of the equipment structure composition and solution flow circuit for preparing ultrapure water by bipolar membrane electrodeionization, showing an embodiment of the method and equipment for preparing ultrapure water by bipolar membrane electrodeionization according to the present invention. Such as figure 2 As shown, the bipolar membrane electrodeionization equipment includes an anode chamber 18 with an anode 10; a cathode chamber 19 with a cathode 11; and several 3-chamber units: the 3-chamber units are composed of concentrated chamber 15, the second desalination chamber 17 and the first desalination chamber 16; there is an anion exchange membrane 12 between the concentration chamber 15 and the second desalination chamber 17 or the anode chamber 18, and between ...

Embodiment 1

[0023] The equipment and solution flow lines for producing ultrapure water by bipolar membrane electrodeionization are as follows: figure 2 As shown, the electrodeionization apparatus has 3 replicate 3-chamber units. Anion and cation exchange membranes and bipolar membranes are AHA anion exchange membranes, CMB cation exchange membranes and BP-1 bipolar membranes provided by Japan Tokuyama Soda Co., Ltd. respectively. Anion and cation exchangers are DOW 650C UPW cation exchange resin and DOW 550A UPW anion exchange resin respectively. The anode is a titanium platinum-plated mesh electrode, and the cathode is a titanium mesh electrode.

[0024] The effective area of each film is 300cm 2 ; The thickness of each compartment is 10mm, that is, the distance between the adjacent membrane and the membrane is 10mm; Fill each desalting chamber and concentrating chamber with about 300mL of corresponding ion exchange resin, of which about 150mL for cation exchange resin It is hydrog...

Embodiment 2

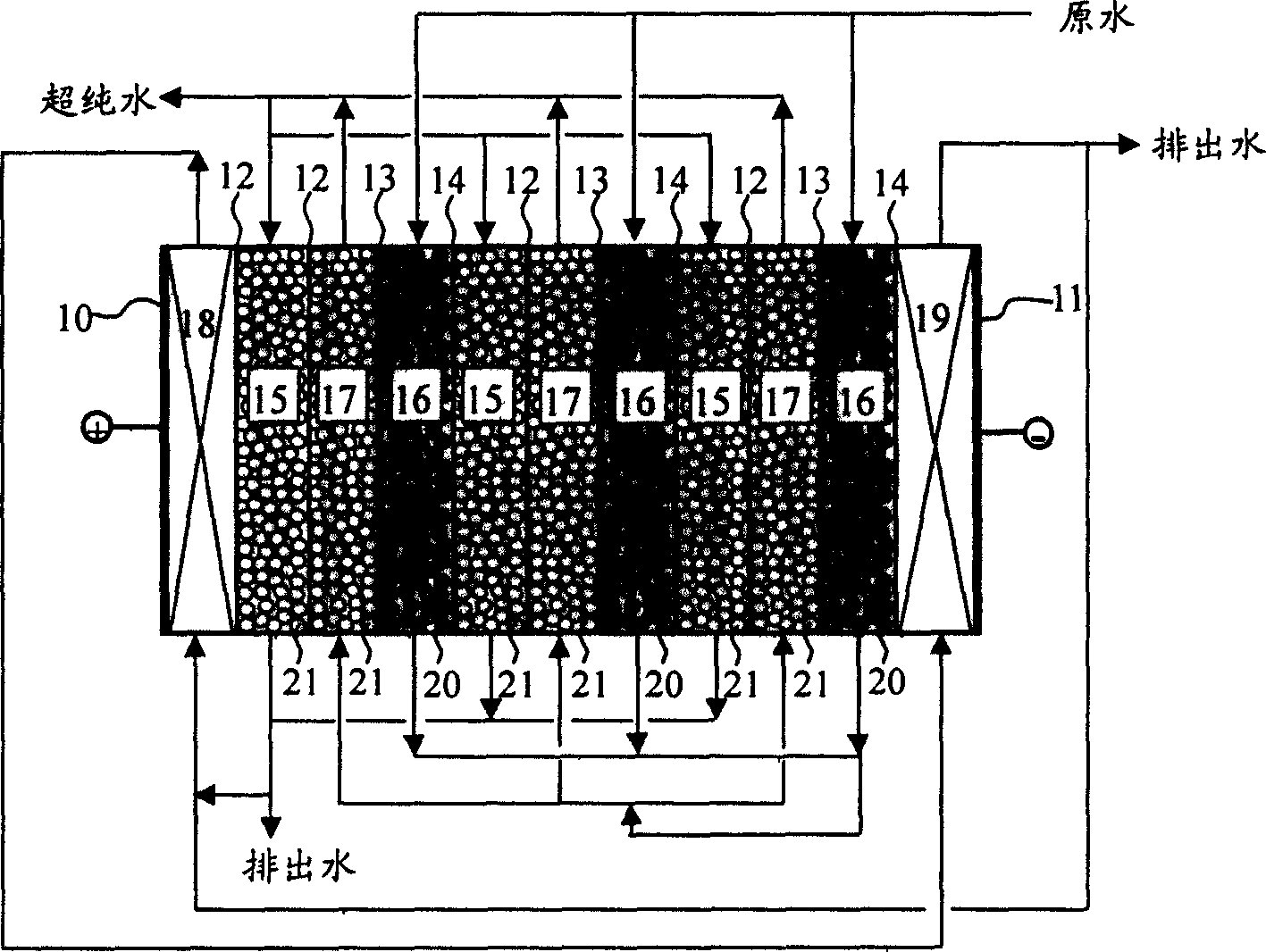

[0030] The bipolar membrane electrodeionization equipment of embodiment 2 is the same as the bipolar membrane electrodeionization equipment of embodiment 1, and the solution flow line is also the same as embodiment 1 except that the source of the water in the concentration chamber is different. In addition, the embodiment 2 Electrode water is also the same as in Example 1. The difference between embodiment 2 and embodiment 1 is: 1. the source of the water inlet of the concentration chamber is different, in embodiment 1, the water inlet of the concentration chamber is a part of ultrapure water, and in embodiment 2, the water inlet of the concentration chamber It is raw water; 2. the raw water is different, the conductivity of the raw water in Example 1 is 2.3 ± 0.1 μS / cm, contains about 100 ppb of silicon, and contains 10 ppb of boron, while the conductivity of the raw water in Example 2 is 25 ± 2 μS / cm, containing silicon About 150ppb, containing boron 20ppb. The operation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com