Desalination device of sea water

A water inlet pipe and water hole technology, which is applied in seawater treatment, general water supply saving, permeation/dialysis water/sewage treatment, etc., can solve the problems of high energy consumption and low efficiency, reduce energy consumption, improve diffusion speed, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

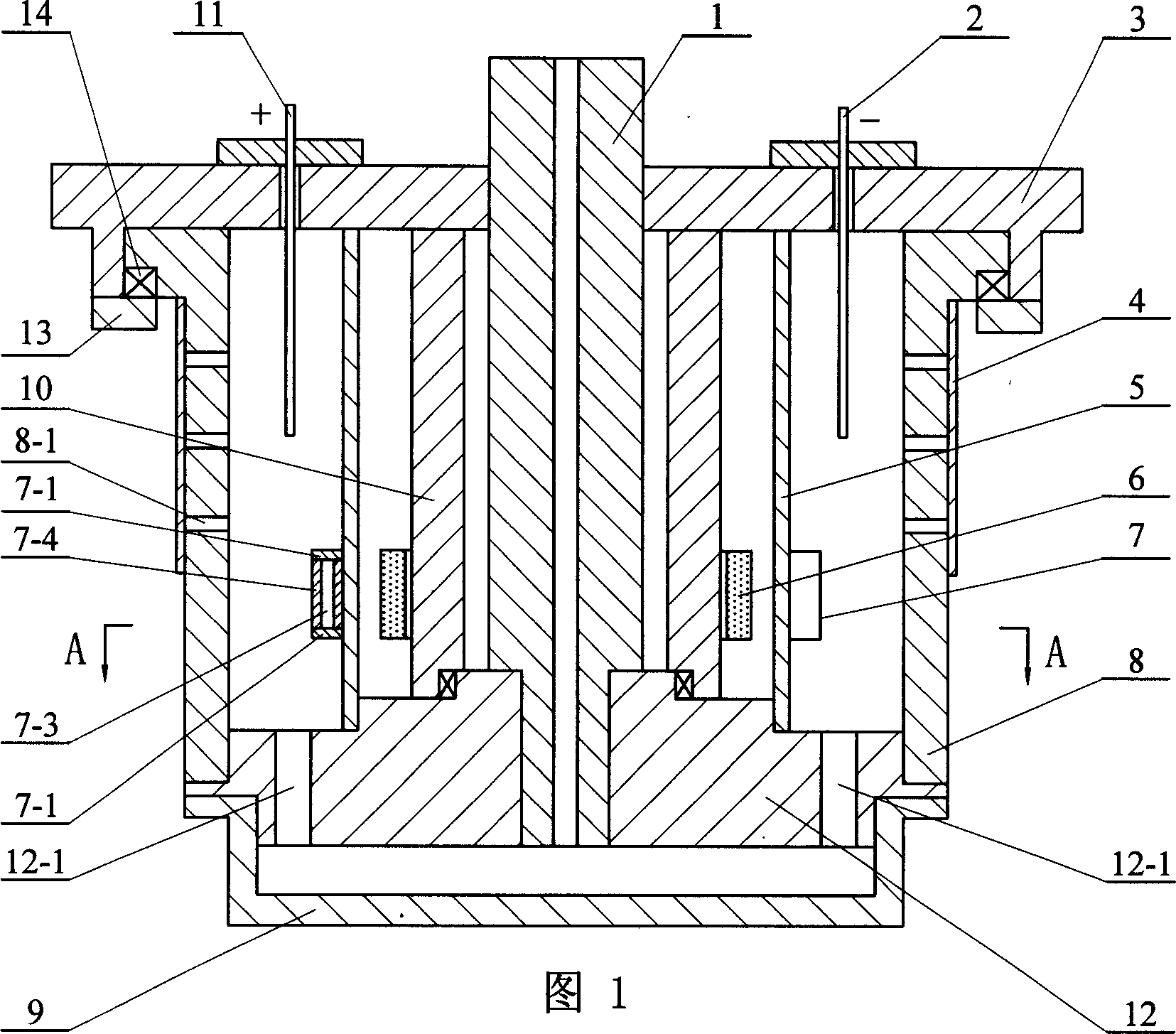

[0006] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 . It consists of water inlet column 1, negative plate 2, positive plate 11, bottom plate 3, reverse osmosis membrane 4, rotor support sleeve 5, stator 6, rotor 7, rotating outer sleeve 8, sealing end cover 9, inner sleeve 10, separator 12 , retaining ring 13 and bearing 14, the upper end of the water inlet pipe column 1 passes through the bottom plate 3 and is fixed on the bottom plate 3, the inner sleeve 10 surrounds the outer circular surface of the water inlet pipe column 1, and one end of the inner sleeve 10 is fixed on the bottom plate 3 On the surface of the inner sleeve 10, the stator 6 is fixed on the outer surface of the inner sleeve 10, the rotor support sleeve 5 surrounds the outer surface of the stator 6, and the outer surface of the rotor support sleeve 5 corresponds to the position of the stator 6. Rotor 7, stator 6 and rotor 7 constitute the electro...

specific Embodiment approach 2

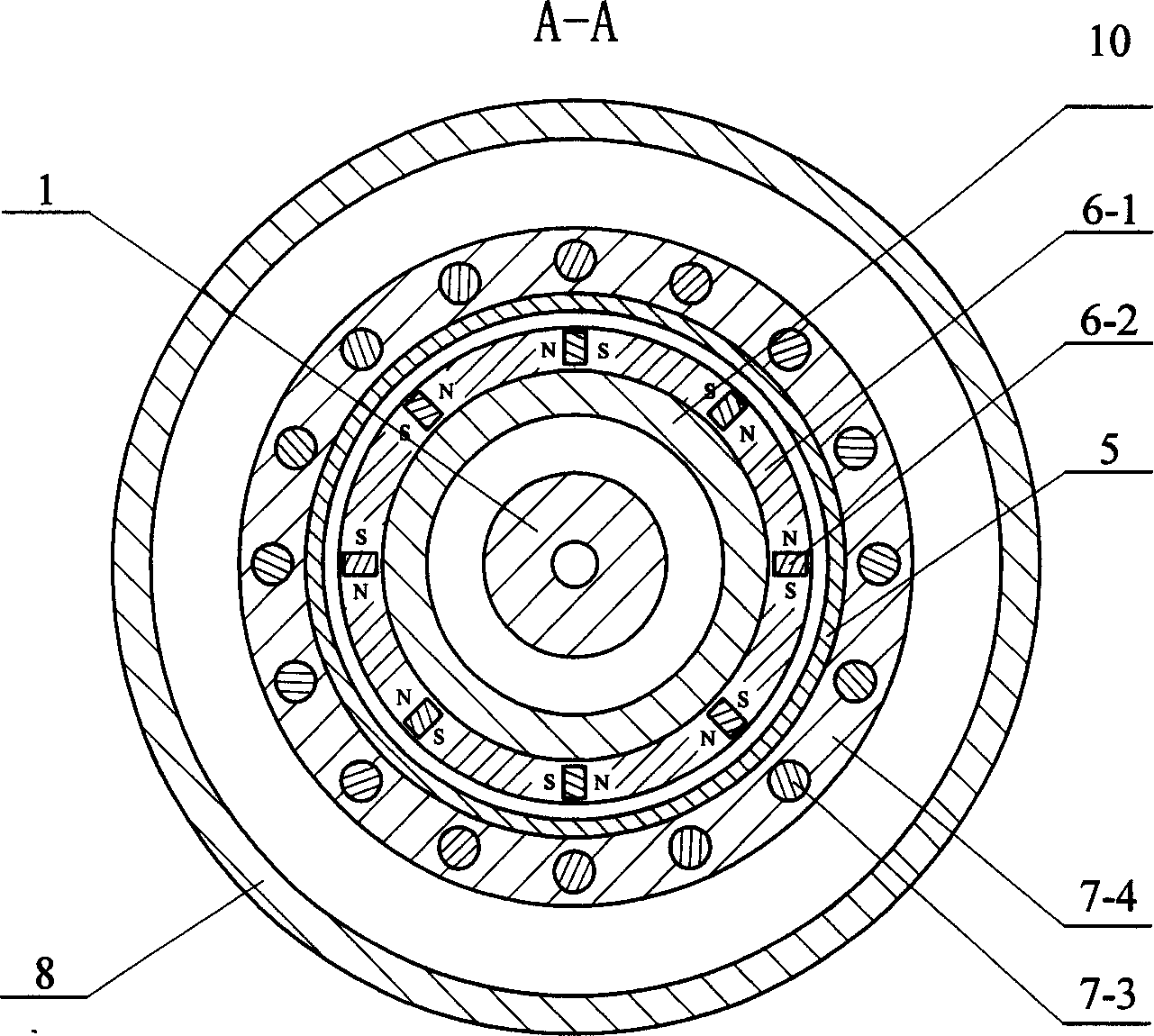

[0007] Specific embodiment two: below in conjunction with Fig. 1 and figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the stator 6 is composed of a stator core 6-1 and several pieces of magnetic steel 6-2, the magnetic steel 6-2 is embedded in the stator core 6-1, and all the magnetic steel 6-1 2 uniformly arranged along the circumferential direction of the stator core 6-1, the magnetic steel 6-2 is magnetized along the tangential direction of the stator core 6-1, and the opposite surfaces of the adjacent magnetic steel 6-2 are filled with the same magnetic polarity. The magnetic steel 6-2 can also be magnetized along the radial direction of the stator core 6-1, as long as the magnetic field lines generated by the magnetic steel 6-2 can cut the rotating rotor. The rotor 7 is composed of a rotor core 7-4, several rotor copper strips 7-3 and two short-circuit rings 7-1. A short-circuit ring 7-1 is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com