Anti-mosquito tensile silk and producing method thereof

A technology for drawing silk and mosquito repellent, applied in the manufacture of rayon, textile and paper making, filament/thread forming, etc. Function retention and other issues, to achieve the effect of easy storage and long-term release, ensuring mosquito repellent effect, and reducing direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

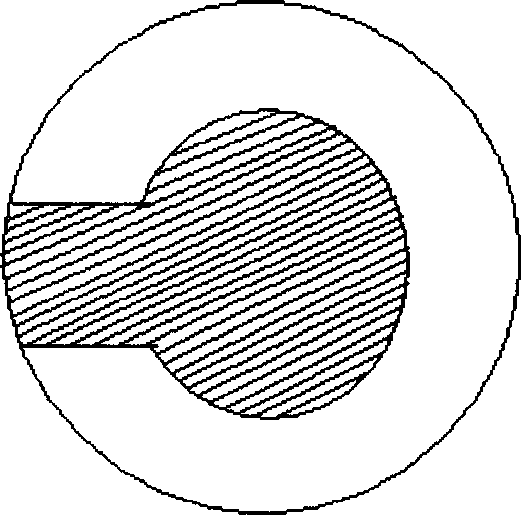

[0033] The formula of the anti-mosquito stretched silk is: the cortex material is dried polyethylene terephthalate; the core layer material is 80 parts of polyethylene, 10 parts of anti-mosquito safety, 6 parts of paraffin, and 4 parts of ethylene-vinyl acetate . After the core layer material is fully mixed according to the formula, it is extruded by twin-screw at 150°C and granulated to produce a fiber core layer material; after the obtained core layer material and the skin layer material are fully dried, press The fiber sheath-core volume ratio of 7: 3, with skin-core composite spinning machine, C-shaped spinneret assembly, under 3300 meters per minute speed, spin out pre-oriented yarn (POY); Then pre-oriented yarn (POY) It is processed on a stretching machine, and then stretched at a stretching temperature of 150° C. and a stretching speed of 1000 m / min, through 1.5 times stretching to obtain a stretched yarn with mosquito repellent function. The cross-section of the obtai...

Embodiment 2

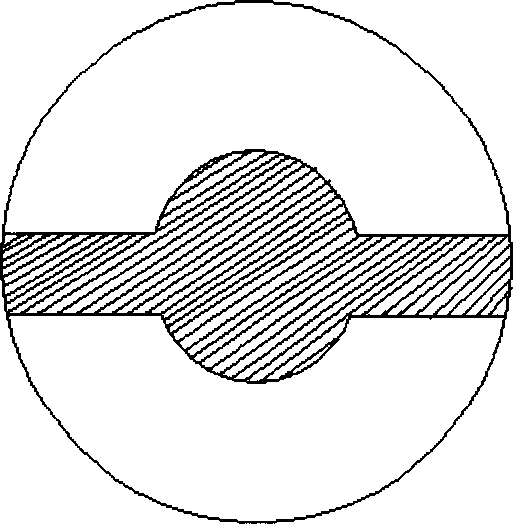

[0035] Take polypropylene with a melt index of 50 for the fiber cortex material; take 85 parts of polypropylene, 6 parts of permethrin, 2 parts of eugenol, 4 parts of ethylene-vinyl acetate (EVA), and 3 parts of polyethylene glycol (PEG) , after fully mixing, twin-screw extrusion at 180°C and granulation to produce fiber core material; after fully drying the skin and core material, according to the volume ratio of fiber skin and core 6:4, in the skin Core composite spinning machine, one-shaped spinning assembly, at a speed of 2500 m / min, spin out pre-oriented yarn (POY); then pre-oriented yarn (POY) is processed on the drawing machine, and then the drawing temperature At 130°C and at a drawing speed of 300 m / min, the stretched yarn with mosquito repellent function was obtained after stretching by 2.5 times. The cross-section of the obtained stretched mosquito repellent yarn is straight, and the communication part between the core layer and the cortex accounts for 10% of the ci...

Embodiment 3

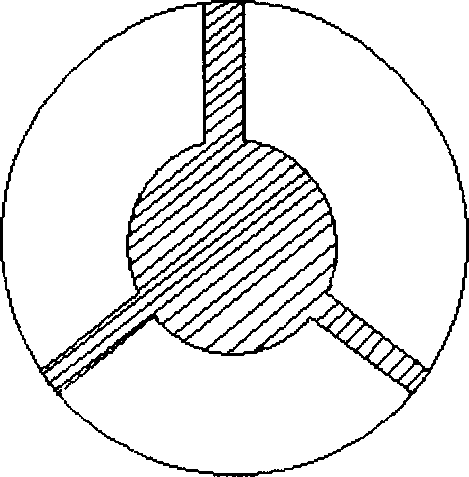

[0037] Take the dried polypropylene terephthalate as the cortex material of the fiber; take 90 parts of polyester with a melting point of 180°C, 5 parts of polyethylene glycol, 2 parts of acrythrin, and 3 parts of pentethrin, and mix them thoroughly Finally, at 200°C, through twin-screw extrusion and granulation, the fiber core layer material is produced; according to the volume ratio of fiber skin and core 4:6, in the skin-core composite spinning machine, the triangular spinneret assembly, at 3100 meters Spin the pre-oriented yarn (POY) at the speed of 1 / min; then process the pre-oriented yarn (POY) on the stretching machine, and then process it twice at a stretching temperature of 140°C and a stretching speed of 600 m / min. stretching to make stretched silk with mosquito repellent function. The cross-section of the obtained mosquito repellent stretched yarn is triangular, and the communication part between the core layer and the cortex accounts for 20% of the perimeter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com