Production of gallium chloride

A gallium chloride and preparation process technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of complex methods, difficult to guarantee the purity of gallium trichloride products, and complicated operation, etc. Simple operation, easy to implement, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

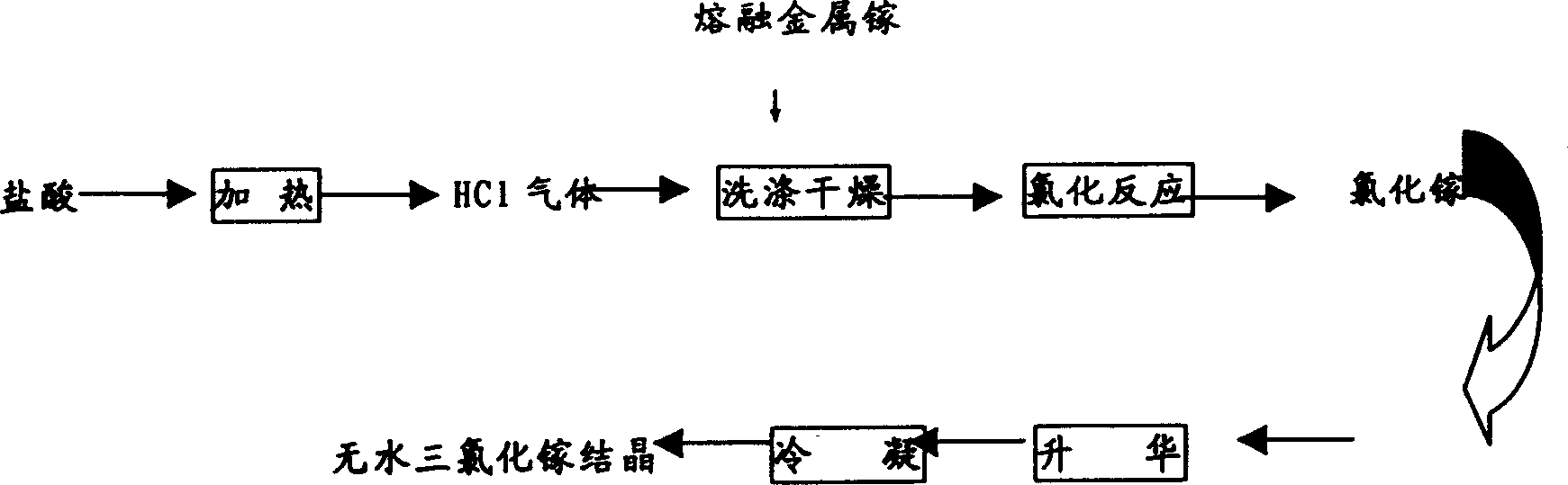

[0021] Use high-purity water and high-purity reagents for raw material preparation, and control the appropriate hydrogen chloride preparation process and chlorination conditions for the reaction of metal gallium and hydrogen chloride: the hydrogen chloride gas obtained by heating hydrochloric acid (about 85 ° C) is dried by calcium chloride and concentrated sulfuric acid. process, put it into a chlorination reactor with metal gallium, maintain the reaction temperature at 200°C, and then produce colorless needle-shaped gallium trichloride. Using ICP-MS analysis and detection technology, the product quality can reach 99.999%.

Embodiment 2

[0023] Use high-purity water and high-purity reagents for raw material preparation, and control the appropriate hydrogen chloride preparation process and chlorination conditions for the reaction of metal gallium and hydrogen chloride: the hydrogen chloride gas obtained by heating hydrochloric acid (about 90 ° C) is dried by calcium chloride and concentrated sulfuric acid. process, put it into a chlorination reactor with metal gallium, keep the reaction temperature at 280°C, and then produce colorless needle-shaped gallium trichloride. Using ICP-MS analysis and detection technology, the product quality can reach 99.999%.

Embodiment 3

[0025] Use high-purity water and high-purity reagents for raw material preparation, and control the appropriate hydrogen chloride preparation process and chlorination conditions for the reaction of metal gallium and hydrogen chloride: the hydrogen chloride gas obtained by heating hydrochloric acid (about 95 ° C) is dried by calcium chloride and concentrated sulfuric acid. process, put it into a chlorination reactor with metal gallium, and maintain the reaction temperature at 240°C to generate colorless needle-shaped gallium trichloride. Using ICP-MS analysis and detection technology, the product quality can reach 99.999%.

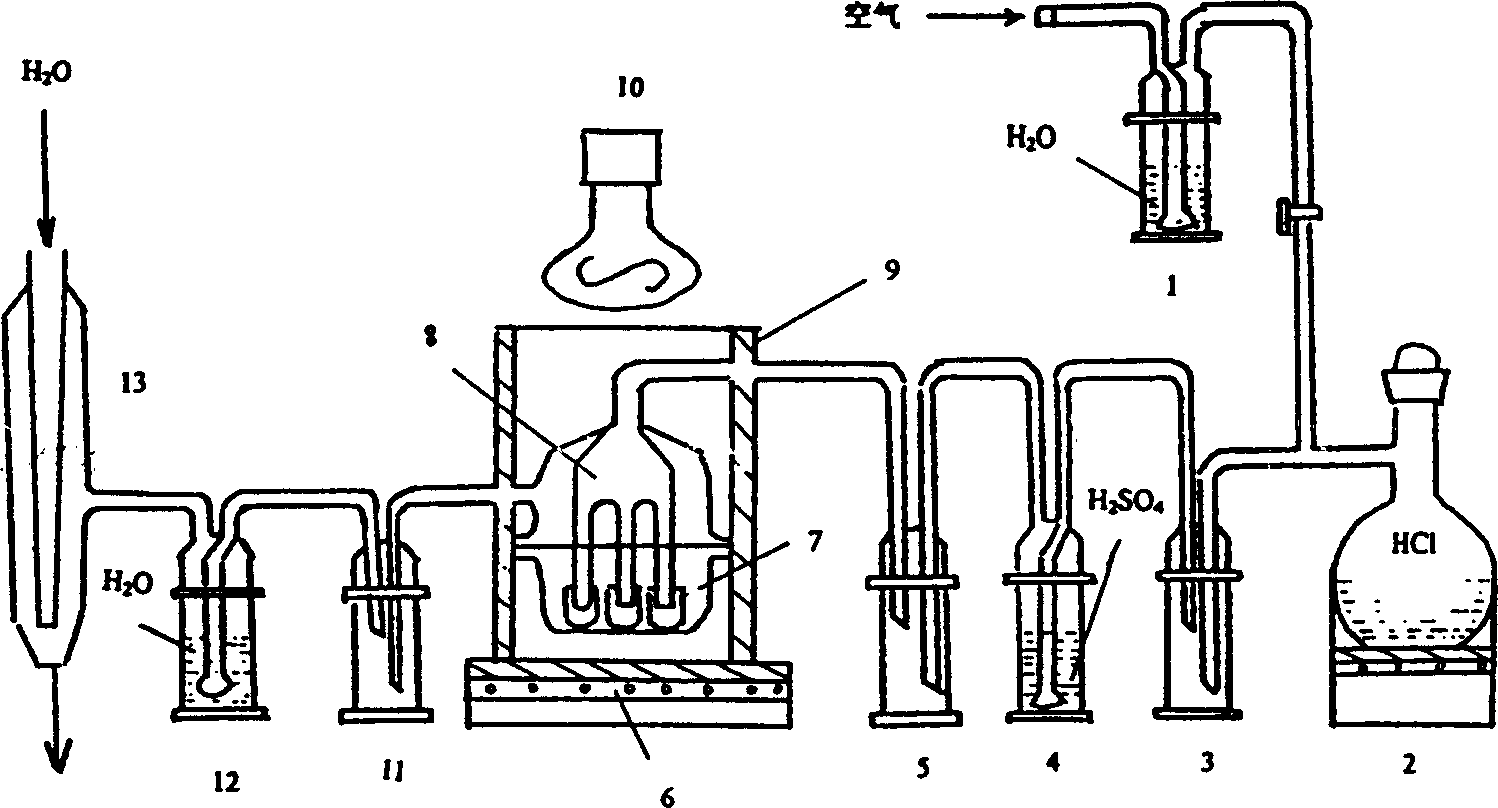

[0026] figure 2 1 is the washing bottle; 2 is the hydrochloric acid heater; 3 is the drying bottle; 4 is H 2 SO 4 5 is a buffer bottle; 6 is an electric heating jacket; 7 is a quartz crucible; 8 is a volatilizer; 9 is a quartz cover; 10 is an infrared lamp; 11 is a condensation crystallization bottle; 12 is a washing bottle;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com