Multi-layer nanometer film coater for reinforcing mould surface

A coating device, nano-multi-layer technology, applied in the direction of coating, sputtering plating, ion implantation plating, etc., can solve problems not related to the structure of the preparation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

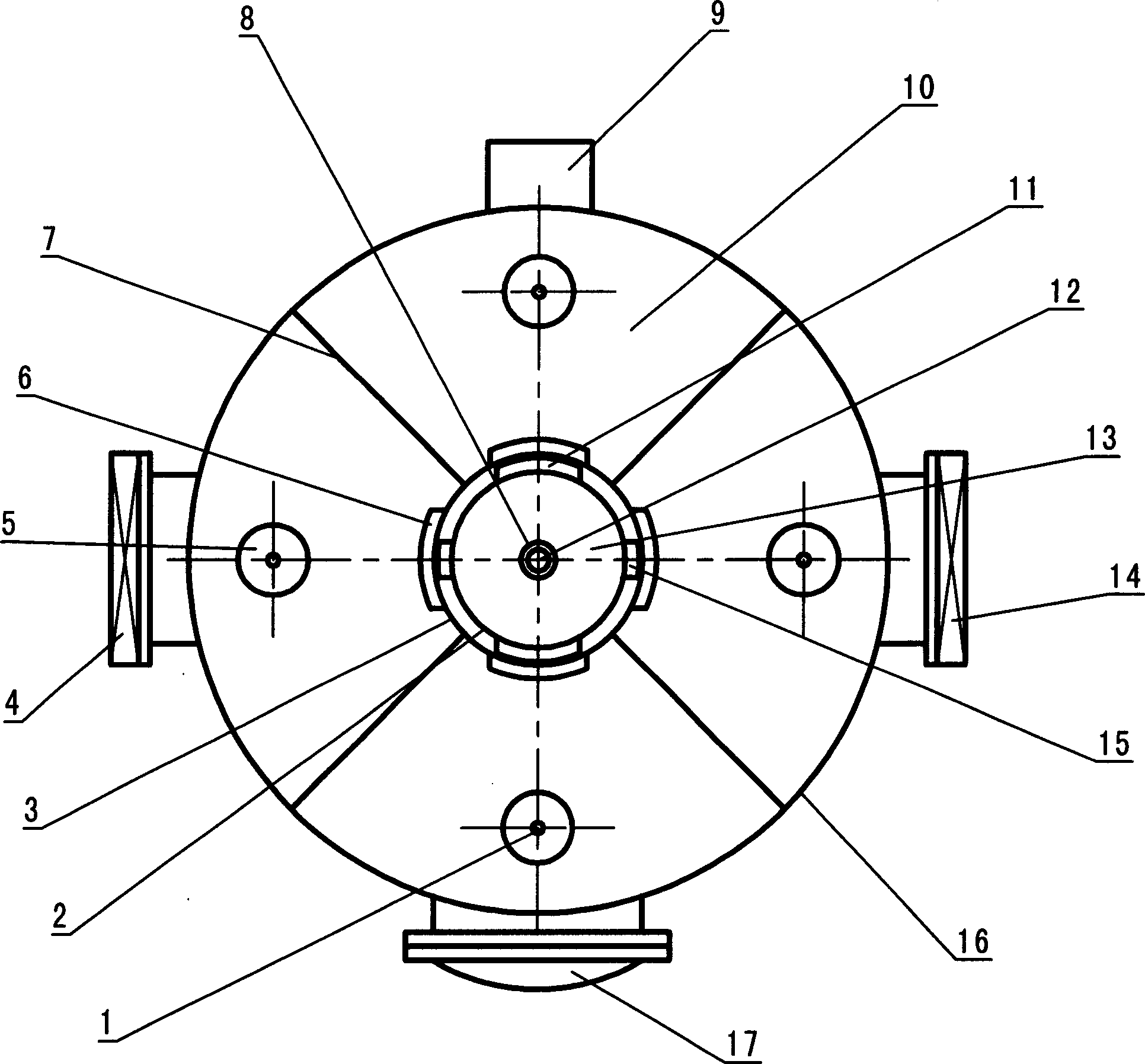

[0019] like figure 1 As shown, a vacuum chamber door 17 , an ion source 9 , a first evaporation device 4 and a second evaporation device 14 are installed on the vacuum chamber wall 16 . Each evaporation device is equipped with an independent gas supply system. A cylindrical partition support frame 3 and a plurality of partitions 7 are installed in the vacuum chamber, and the cylindrical partition support frame 3 and the partitions 7 divide the vacuum chamber into four isolation chambers 10 . There are four openings 6 on the cylindrical partition support frame 3 . A central air extraction pipe 2 is arranged in the cylindrical partition support frame 3 , and there are two first openings 15 and two second openings 11 on the central air extraction pipe 2 . The first openings 15 correspond to the evaporation device, the second openings 11 intersect between the first openings 15 , and the area of the second openings 11 is larger than that of the first openings 15 . Workpiece ra...

Embodiment 2

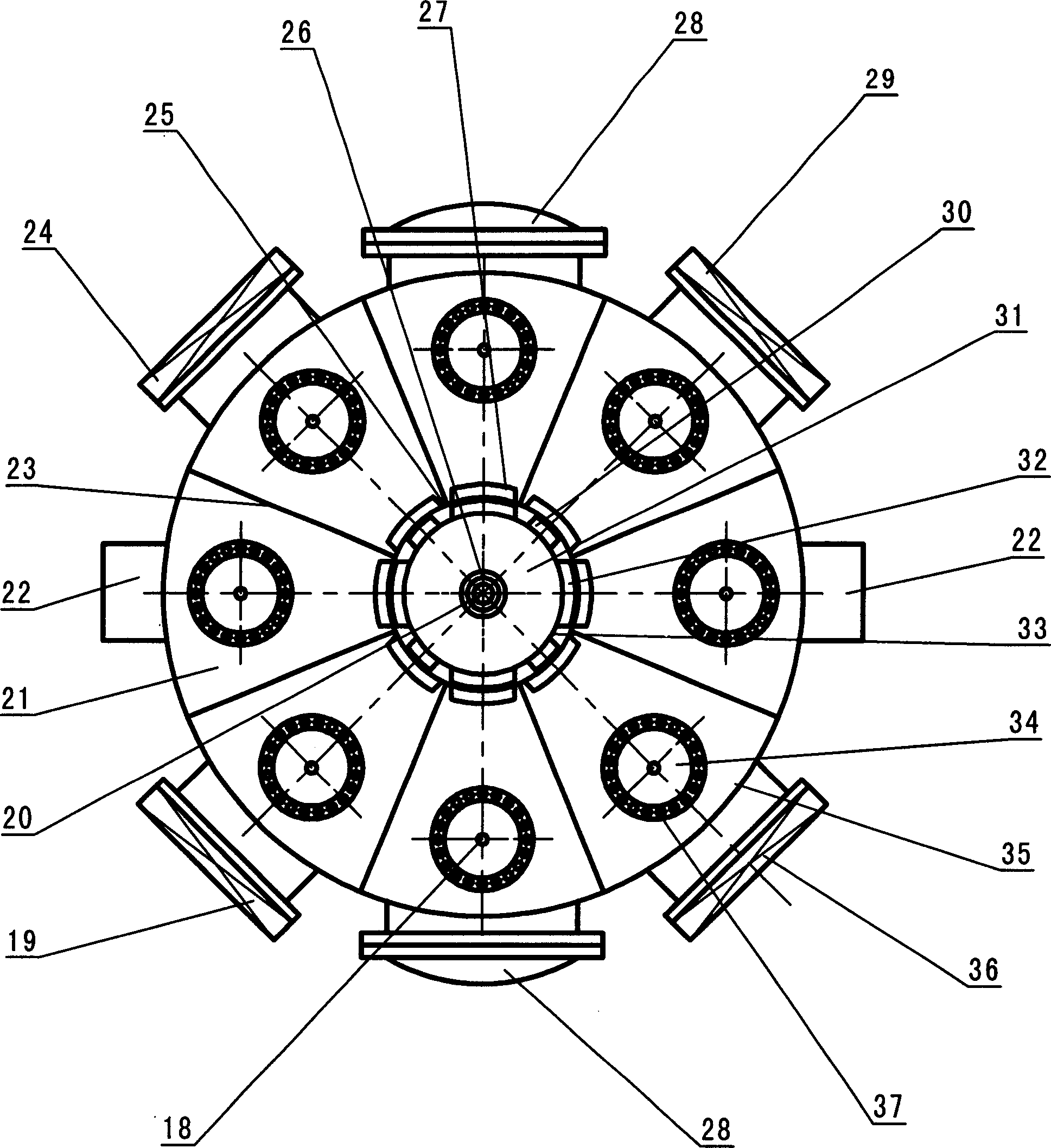

[0025] like figure 2 As shown, two vacuum chamber doors 28 , two ion sources 22 , a first evaporating device 19 , a second evaporating device 24 , a third evaporating device 29 and a fourth evaporating device 36 are mounted on the vacuum chamber wall 35 . Each evaporation device is equipped with an independent gas supply system. A cylindrical partition supporting frame 25 and a plurality of partitions 23 are installed in the vacuum chamber, and the cylindrical partition supporting frame 25 and the partitions 23 divide the vacuum chamber into eight isolation chambers 21 . There are a plurality of openings 27 on the cylindrical partition support frame 25 . A central air extraction pipe 33 is disposed in the cylindrical partition support frame 25 , and there are four first openings 30 and four second openings 32 of the central air extraction pipe 33 . The first openings 30 correspond to the evaporation device, the second openings 32 intersect between the first openings 30 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com