Collagen-chitin and silicon rubber bilayer skin regeneration support and its preparation method

A technology of skin regeneration and chitosan, applied in medical science, prosthesis, etc., can solve the problem of insufficient supply of autologous skin, achieve good elasticity and clinical ease of operation, promote healing, and prevent bacterial invasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

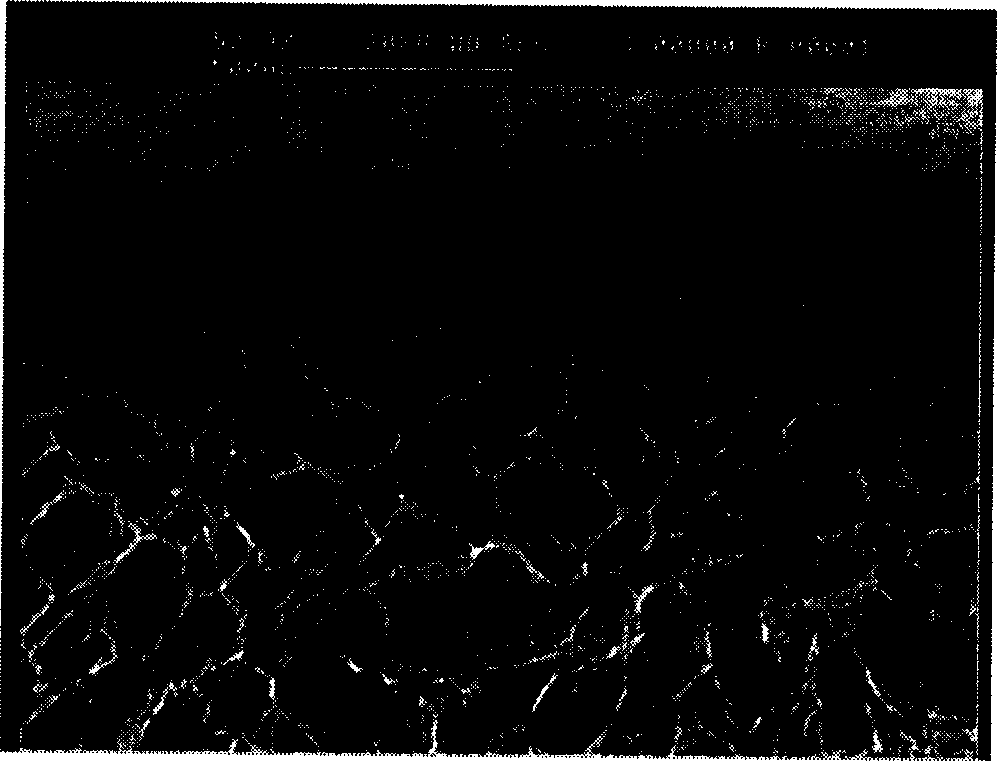

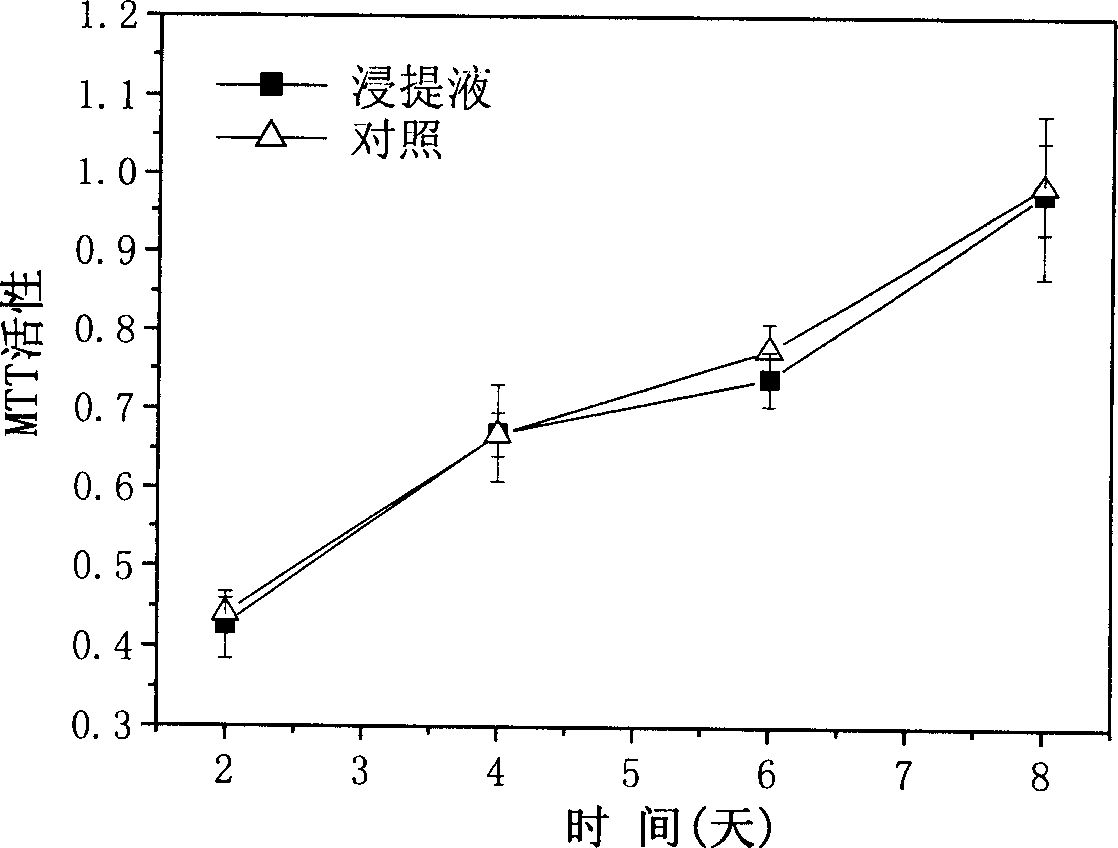

Embodiment 1

[0026] Collagen and chitosan were dissolved in 3% acetic acid solution respectively, and the preparation concentration was 0.5% collagen solution and 0.5% chitosan solution, and the chitosan solution was dropped into the collagen solution, wherein the chitosan The content is 10%, stir evenly and vacuum degassing; use the freeze-lyophilization method, freeze at -20°C for 2 hours, and then freeze-dry for 24 hours. Freeze-dried collagen / chitosan scaffolds were cross-linked in a vacuum oven at 105°C for 12 hours, cross-linked with 0.25% glutaraldehyde solution at 4°C for 24 hours, rinsed repeatedly with triple distilled water, and then frozen again - Lyophilization to obtain a cross-linked collagen-chitosan porous scaffold. On the surface of a silicone rubber film with a thickness of about 0.14 mm, a gelatin adhesive with good biocompatibility was added at 0.25 mg / cm 2 Evenly coated on the surface of the silicone rubber film, and then the collagen-chitosan porous scaffold was gen...

Embodiment 2

[0028] Collagen and chitosan were dissolved in 3% acetic acid solution respectively, and the preparation concentration was 0.5% collagen solution and 0.5% chitosan solution, and the chitosan solution was dropped into the collagen solution, wherein the chitosan The content is 10%, stir evenly and vacuum degassing; use the freeze-lyophilization method, freeze at -20°C for 2 hours, and then freeze-dry for 24 hours. Freeze-dried collagen-chitosan scaffolds were cross-linked in a vacuum oven at 105°C for 12 hours, cross-linked with 0.25% glutaraldehyde solution at 4°C for 24 hours, rinsed repeatedly with three-distilled water, and then frozen again - Lyophilization to obtain a cross-linked collagen-chitosan porous scaffold. On the surface of a silicone rubber film with a thickness of about 0.14 mm, α-cyanoacrylate octyl adhesive with good biocompatibility was added at 0.25 mg / cm 2 Evenly coated on the surface of the silicone rubber film, and then the collagen-chitosan porous scaff...

Embodiment 3

[0030]Collagen and chitosan were dissolved in 0.3% acetic acid solution respectively to prepare a 0.5% collagen solution and a 0.5% chitosan solution, and the chitosan solution was dropped into the collagen solution, wherein the chitosan The content is 5%, stir evenly and vacuum degassing; use freeze-lyophilization method, freeze to solid at -5°C, and then freeze-dry for 24 hours. Freeze-dried collagen / chitosan scaffolds were cross-linked in a vacuum oven at 80°C for 12 hours, cross-linked with 0.05% glutaraldehyde solution at 4°C for 1 hour, rinsed repeatedly with triple distilled water, and then frozen again - Lyophilization to obtain a cross-linked collagen-chitosan porous scaffold. On the surface of a silicone rubber film with a thickness of about 0.05 mm, α-cyanoacrylate octyl adhesive with good biocompatibility was added at 0.05 mg / cm 2 Evenly coated on the surface of the silicone rubber film, and then the collagen-chitosan porous scaffold was gently placed on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com