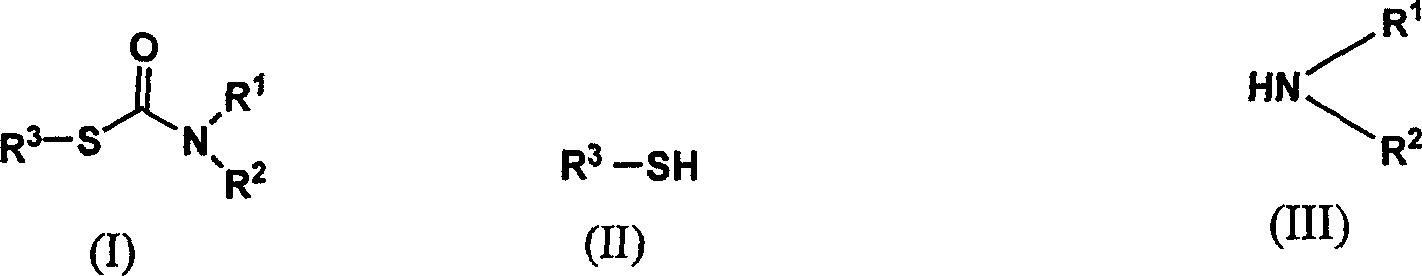

Method of synthesizing thiocarbamate by 'one pot method'

A technology for synthesizing thiocarbamate and carbamate, applied in organic chemistry, etc., can solve the problems of expensive catalyst, harsh reaction conditions, difficult post-processing, etc., and achieve great potential social and economic benefits, mild reaction conditions, Easy to store for easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

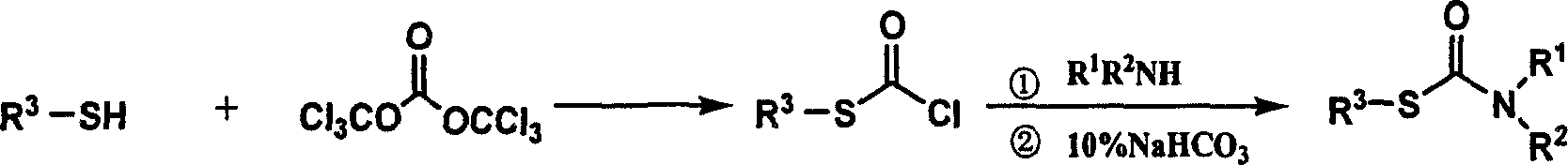

Method used

Image

Examples

Embodiment 1

[0016] The molar ratio of the feed material is substituted mercaptan: bis(trichloromethyl)carbonate: amine is 1.0:0.33:1.0, wherein the substituted mercaptan is p-cresol, the amine compound is aniline, and the organic solvent is methylene chloride , and its dosage is 15 times of the quality of p-cresol.

[0017] In a 150 mL four-neck flask equipped with a thermometer, a reflux condenser, and mechanical stirring, 40 mmol of p-cresylthiophenol, 13.3 mmol of bis(trichloromethyl)carbonate and 74.4 g of dichloromethane were added. Start stirring, dissolve, and react at room temperature for 1 hour. TLC traces until the reaction of the raw materials is complete. Cool the reaction solution to 0-5°C in an ice bath. Raise the temperature to reflux, stir for 2 h, cool to room temperature after the reaction, and wash the reaction solution with 10% NaHCO3, H2O, and saturated brine to obtain an aqueous phase and an organic phase, discard the aqueous phase, and dry the organic layer with an ...

Embodiment 2

[0019] The molar ratio of the feed material is substituted mercaptan: bis(trichloromethyl)carbonate: amine is 1.0:0.40:1.0, wherein the substituted mercaptan is p-cresol, the amine compound is aniline, and the organic solvent is methylene chloride , and its dosage is 15 times of the quality of p-cresol.

[0020] Others are with embodiment 1. The yield of the obtained thiocarbamate product is 78.8%, the melting point of the product is 129.0-130.0° C., and the purity is 98.5%.

Embodiment 3

[0022] The molar ratio of the feed material is substituted thiol: bis(trichloromethyl)carbonate: amine is 1.0:0.50:1.0, wherein the substituted mercaptan is p-cresol, the amine compound is aniline, and the organic solvent is methylene chloride , and its dosage is 20 times the mass of p-cresol.

[0023] Others are with embodiment 1. The yield of the obtained thiocarbamate product is 80.3%, the melting point of the product is 129.2-130.1° C., and the purity is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com