Electric Source adapter and its mfg. method

A technology of power adapter and manufacturing method, which is applied in the direction of transformer/inductor casing, transformer/inductor cooling, heat exchange equipment, etc., can solve problems such as poor heat dissipation, and achieve simple manufacturing method, stable mechanical performance, and good heat dissipation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

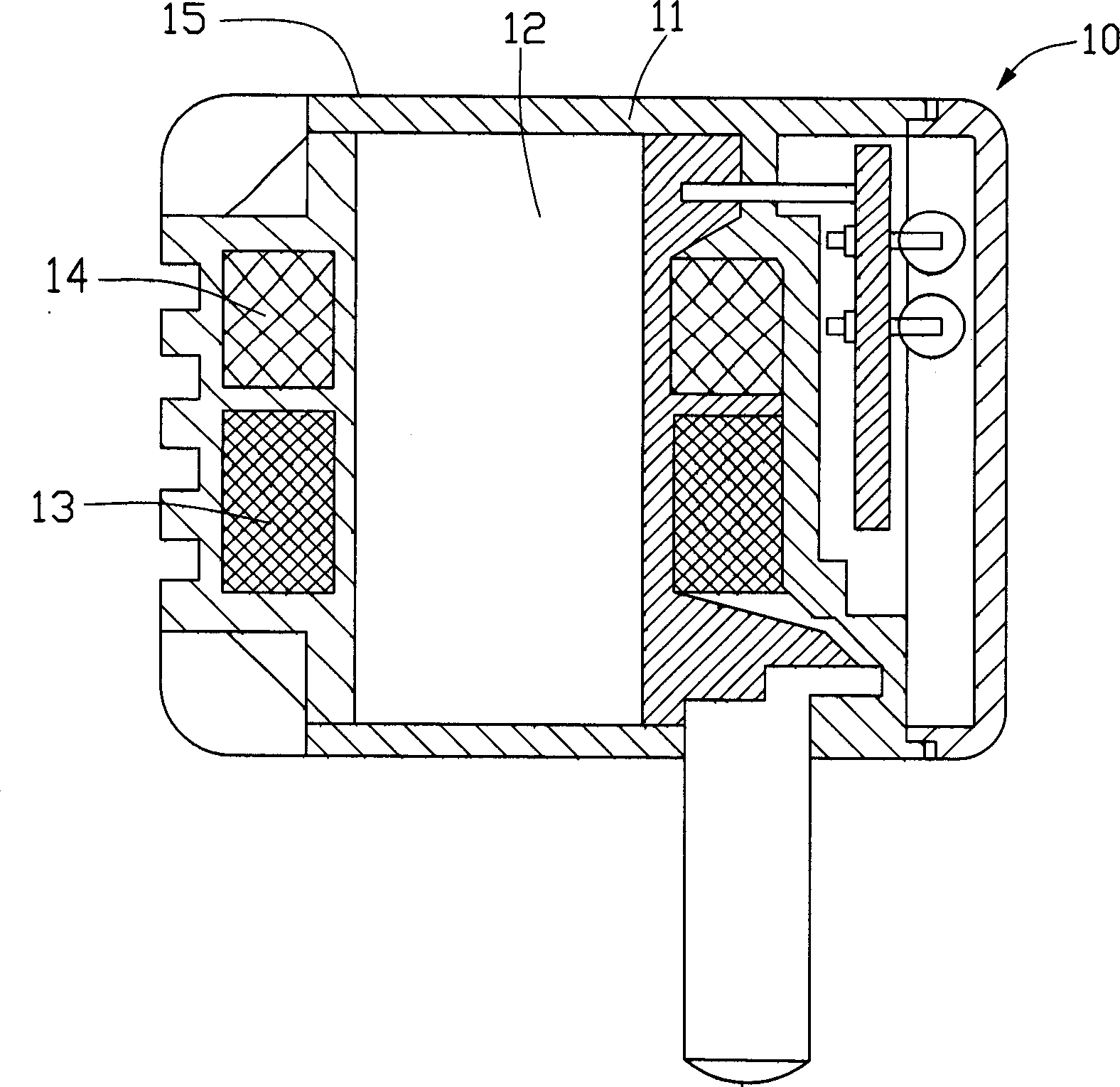

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

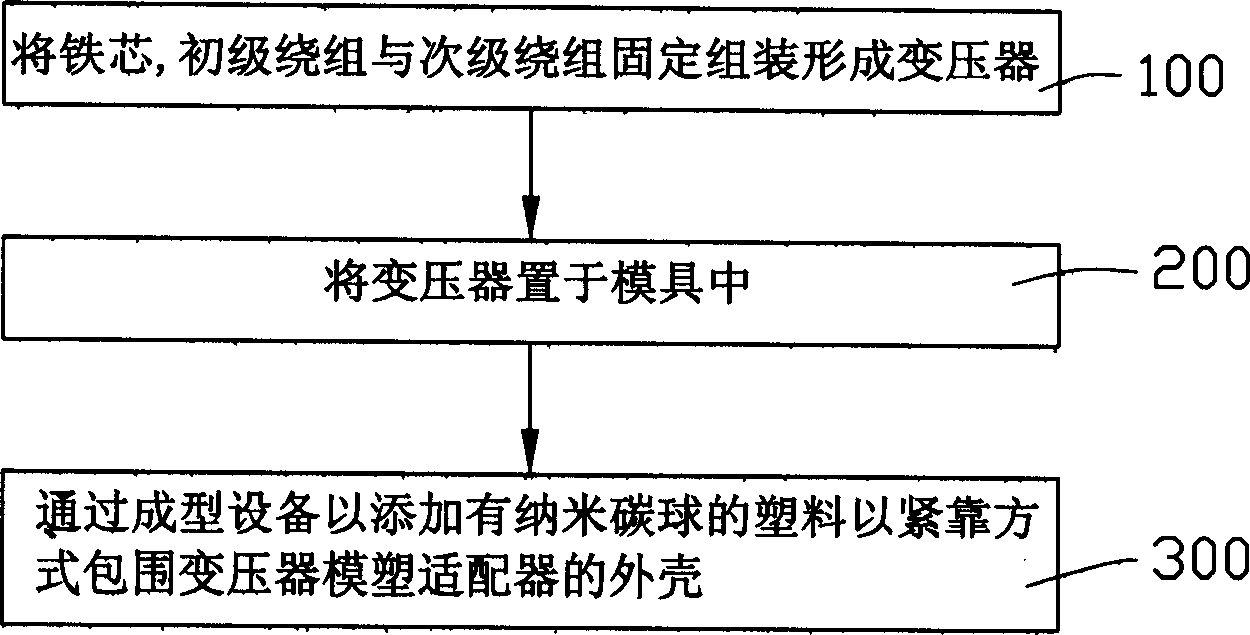

[0015] see figure 1 , the present invention provides a kind of manufacturing method of power adapter, it comprises the following steps:

[0016] Step 100 is to fix and assemble the iron core, primary winding and secondary winding to form a transformer;

[0017] Step 200 is placing the transformer in the mold;

[0018] Step 300 is to use plastics added with nano carbon spheres to form a shell that surrounds the transformer molded adapter in a close manner through a molding device;

[0019] Wherein, the molding process adopted in step 300 mainly includes: injection molding and extrusion molding.

[0020] Injection molding further includes the following steps:

[0021] providing an injection molding machine;

[0022] Make plastic into pellets or powder and mix them evenly with nano-carbon spheres;

[0023] Put the mixture obtained after mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com