Ti-containing Sn-based alloy and its smelting preparation method

A technology of base alloy and alloy, applied in the field of preparation of Sn-based alloy, to achieve the effects of good repeatability, easy mass production and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

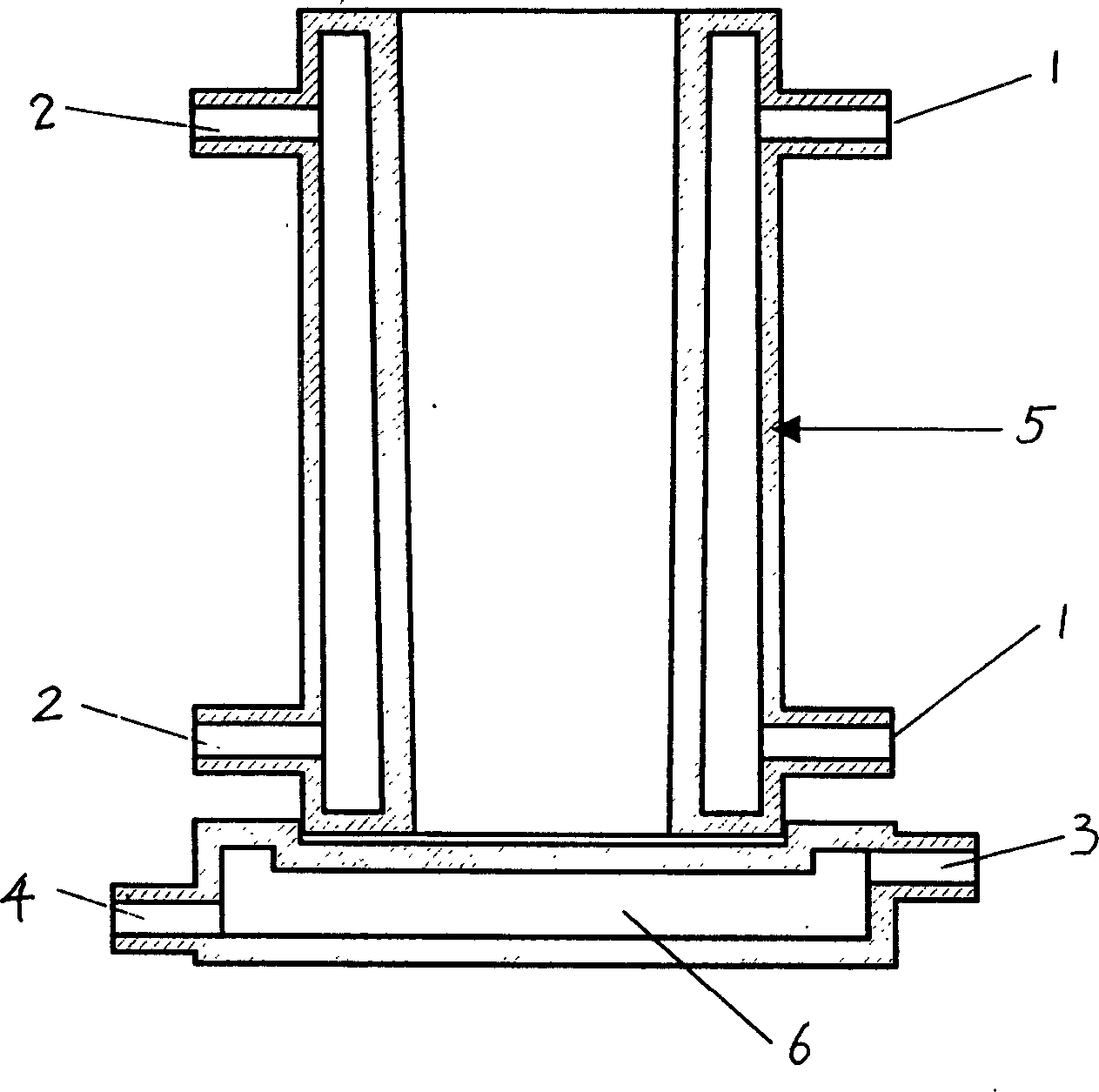

[0018] Use Sn and Sn-27%Ti (weight content) master alloy with a weight purity of 99.9% as raw materials, and put the raw materials with a total weight of 15-20Kg (wherein Ti weight content is 2.0%) into the graphite crucible of the medium frequency induction furnace , vacuum the medium frequency induction furnace to 10 -1 Pa is filled with Ar gas, and then vacuumized and filled with Ar gas. This process is repeated 3 times and then filled with Ar gas to 0.25-0.3Mpa. Raise the temperature of the raw material to 1200°C and keep it for 20 minutes to fully melt the Sn and Sn-Ti master alloy, then raise the temperature to 1450°C, and then quickly pour it into a water-cooled copper mold to obtain a Ti-containing Sn-based alloy ingot. The main part of the water-cooled copper mold has an outer diameter of Φ180mm, a height of 300mm, and an inner diameter of Φ105mm (upper end) and Φ96mm (lower end). The surface of the ingot and the upper and lower bottoms of the ingot were peeled off, ...

example 2

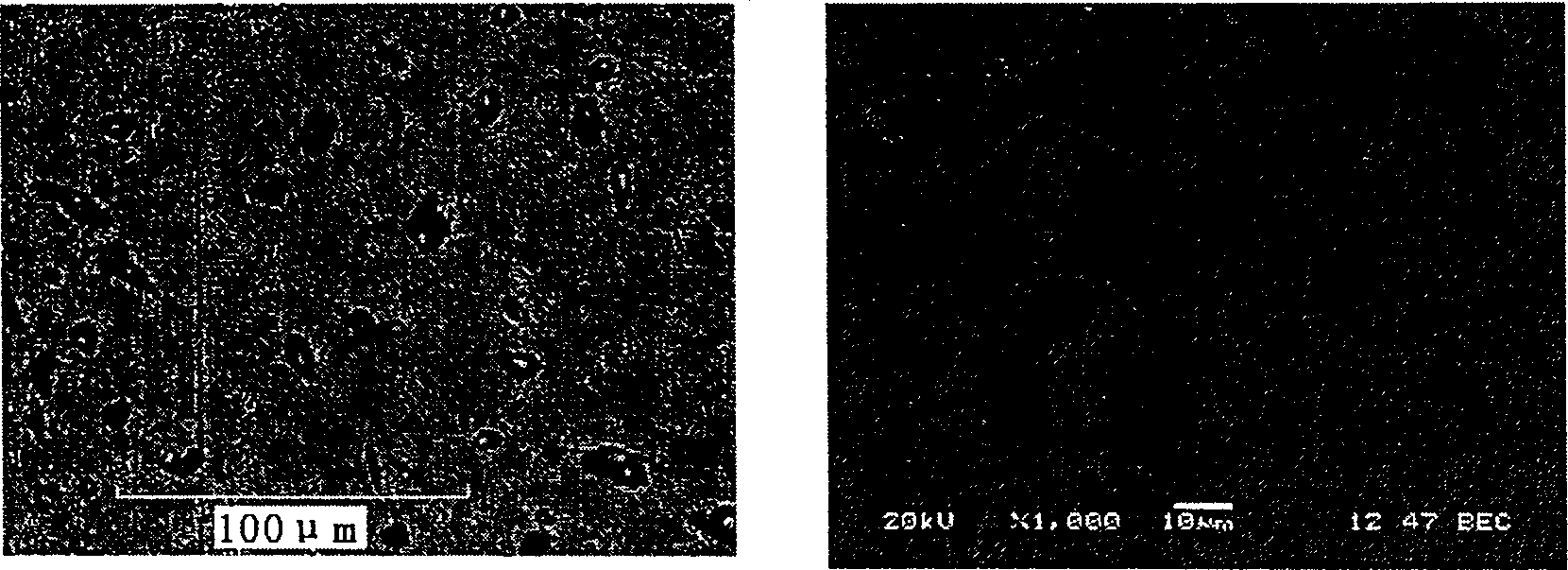

[0020] The smelting method of the Ti-containing Sn-based alloy is the same as that of Example 1, except that the content of Ti is adjusted when the raw materials are prepared, and the component analysis result of the weight content of Ti in the Ti-containing Sn-based alloy light ingot is 3%. In the Sn-based alloy, Ti is distributed in the Sn matrix in the form of Sn-Ti compound in fine dispersed particles. Sn-Ti compound is 100% Ti 6 sn 5 , the maximum size of the dispersed particles is not greater than 20 μm, and the average size is 5-10 μm.

example 3

[0022] The smelting method and composition ratio of the Ti-containing Sn-based alloy are the same as in Example 1, except that during the smelting process, when the raw material is heated up to 1300°C and kept for 20 minutes, the temperature is raised to ~1550°C, and then quickly poured into a special water-cooled copper mold. A Ti-containing Sn-based alloy ingot is obtained. At this time, the ingot and the special water-cooled copper mold have partial adhesion, which makes demoulding difficult, and the water-cooled copper mold suffers some damage. The Ti content of the Sn-based alloy and the phase composition and size of the dispersed particles are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com