Resin level detection method for ultraviolet curing quick forming process

A molding process and resin liquid technology, applied in liquid level indicators for physical variable measurement, liquid/fluid solid measurement, measuring devices, etc., can solve problems such as inability to measure liquid level signals, weak scattered light intensity, etc., and achieve measurement High resolution, improved quality, and the effect of meeting detection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

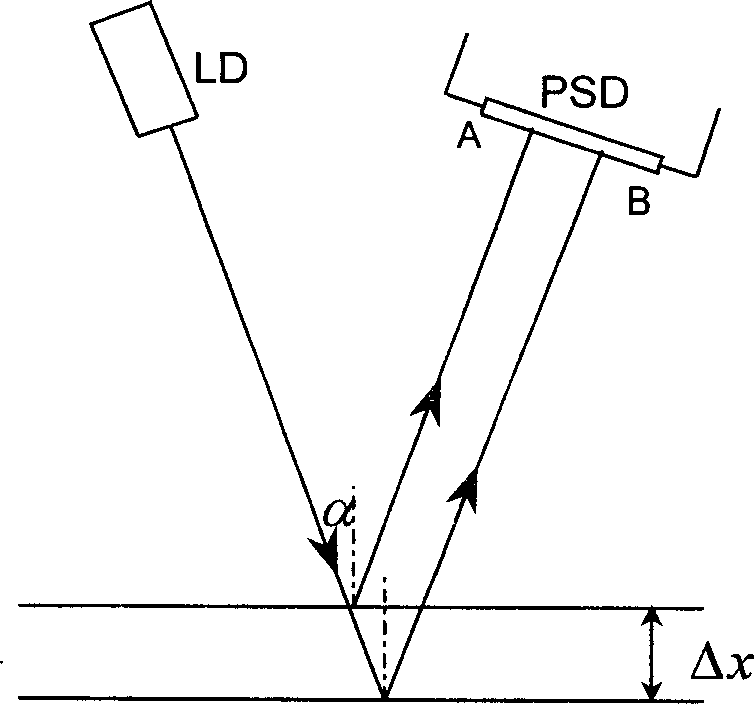

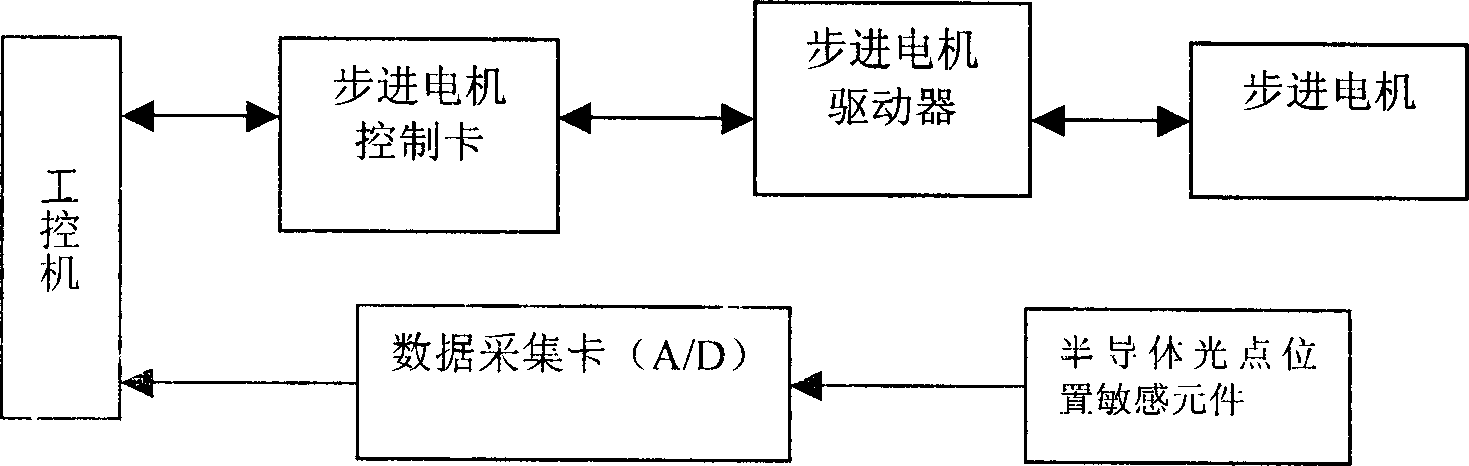

[0017] The resin liquid level detection method used in the photocuring rapid prototyping process of the present invention adopts the semiconductor light spot position sensitive element PSD as the sensitive element, and the semiconductor laser diode (LD) as the light source, and detects the movement of the resin liquid level based on the principle of reflective inclination angle measurement quantity.

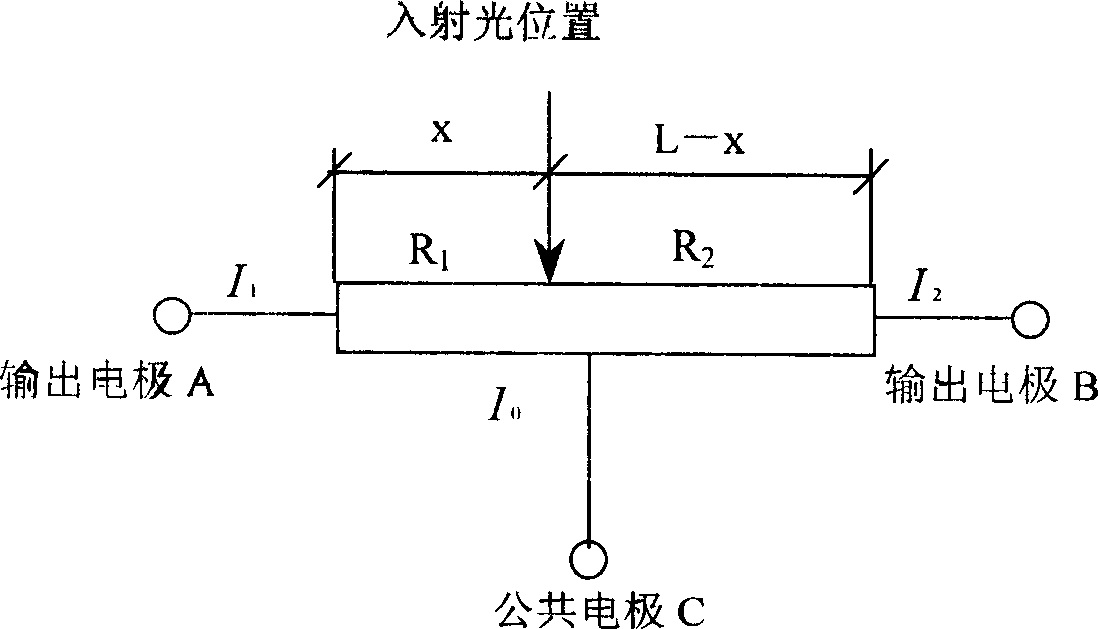

[0018] 1. Basic structure and characteristics of PSD devices

[0019] PSD is a semiconductor light point position sensitive element, its basic structure is as attached figure 1 shown. When a light beam shines on a certain point on the photosensitive surface, a certain photogenerated current I will be generated on the photosensitive surface. 0 . This current is I 1 and I 2 respectively flow to the two output electrodes, I 1 and I 2 The shunt relationship depends on the equivalent resistance from the incident light spot position to the two poles, and because the P-layer impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com