Process for producing aluminium hydroxide

A technology of aluminum hydroxide and alumina, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of low decomposition rate and decomposition rate, affecting decomposition efficiency, complex process equipment, etc. The effect of shortening the decomposition time, increasing the decomposition rate and rate, and eliminating the evaporation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

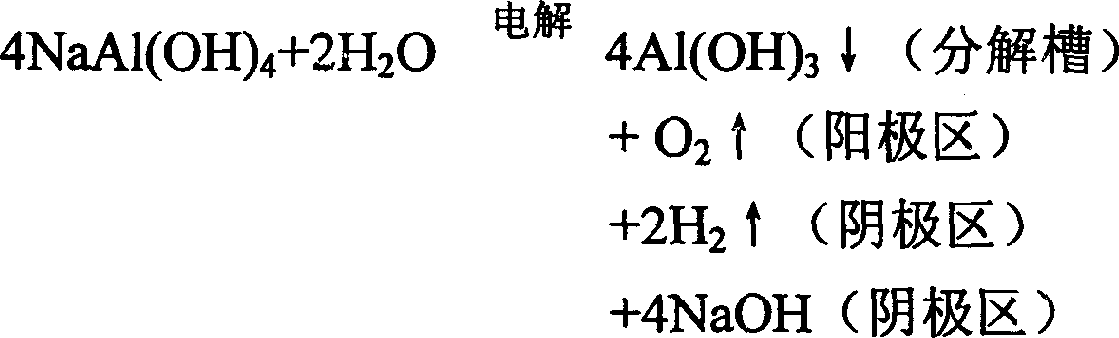

Method used

Image

Examples

Embodiment 1

[0032] The caustic concentration is 145g / l, α K 1.50 Bayer method semen, the ion membrane used is the Nafion cation exchange membrane produced by DuPont Company for ion membrane electrolysis, and the current density is 1.0A / dm 2 After energizing for 2 hours, introduce the seed crystal decomposition tank, add the seed crystal with a seed crystal ratio of 0.1 in the decomposition tank to carry out the Bayer process, and after 12 hours of decomposition, the alumina decomposition rate is 60%.

Embodiment 2

[0034] The caustic concentration is 155g / l, α K The Bayer method semen of 2.00, the ion membrane used is the Nafion cation exchange membrane produced by DuPont Company for ion membrane electrolysis, and the current density is 10.0A / dm 2 After energizing for 4 hours, introduce the seed crystal decomposition tank, add the seed crystal seed ratio of 3.0 in the decomposition tank to carry out the Bayer process, after 4 hours of decomposition, the decomposition rate of aluminum oxide is 70%.

Embodiment 3

[0036] The caustic concentration is 165g / l, α K The Bayer method semen of 1.70, the ionic membrane used is the Nafion cation exchange membrane produced by DuPont Company for ionic membrane electrolysis, and the current density is 5.0A / dm 2 After energizing for 4 hours, introduce the seed crystal decomposition tank, add the seed crystal seed ratio of 2.0 in the decomposition tank to carry out the Bayer process, after 8 hours of decomposition, the alumina decomposition rate is 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com