Microorganism mediated distillers' grain, straw and coal gangue full-element bio-organic fertilizer production technology and system

A technology of bio-organic fertilizer and production process, which is applied to the treatment of bio-organic parts, fertilizers made of bio-waste, organic fertilizers, etc., can solve the problems of chemical fertilizer abuse and waste problems, reduce emissions, reduce environmental burdens, and accelerate The effect of decomposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention will be described in detail below in conjunction with the accompanying drawings.

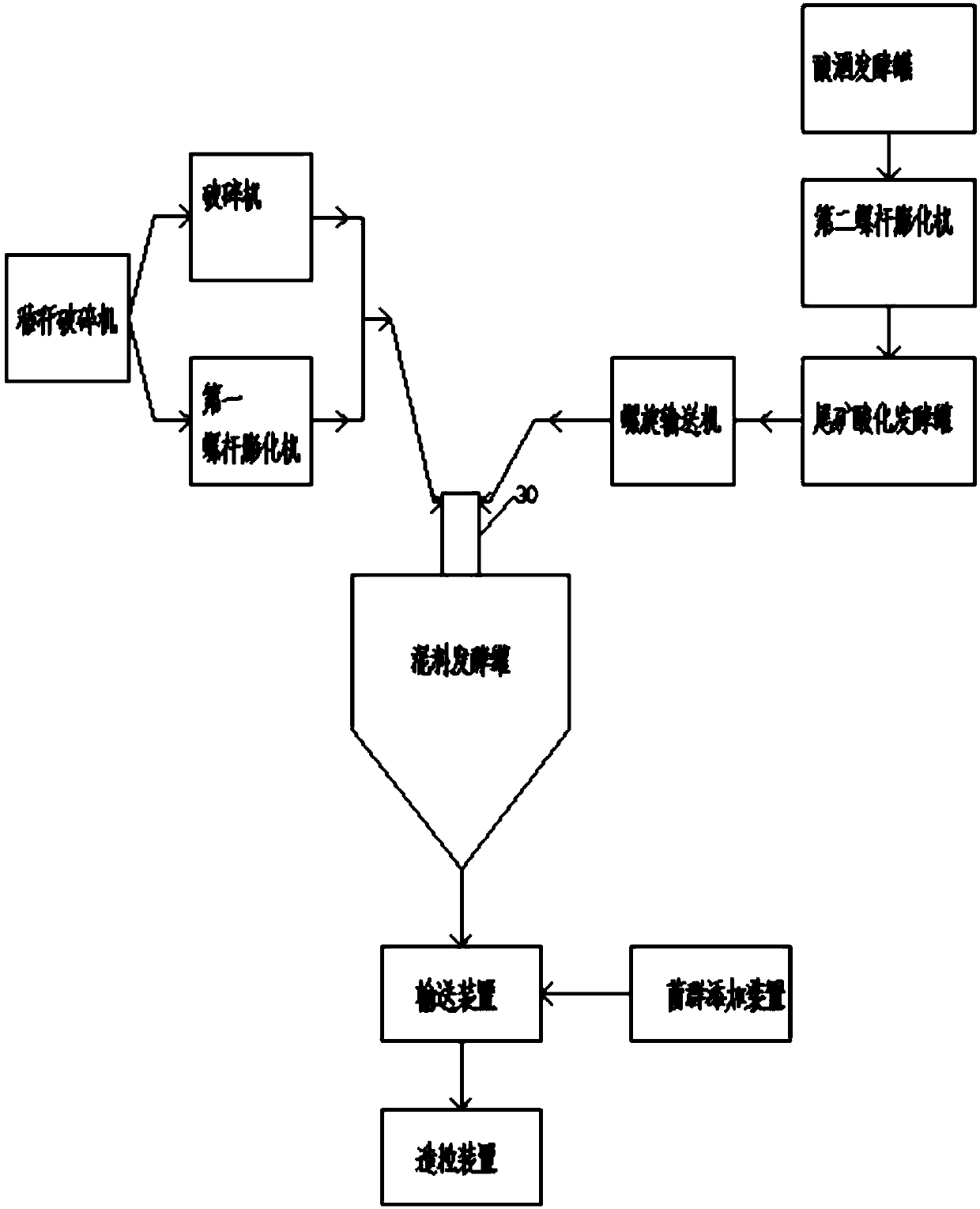

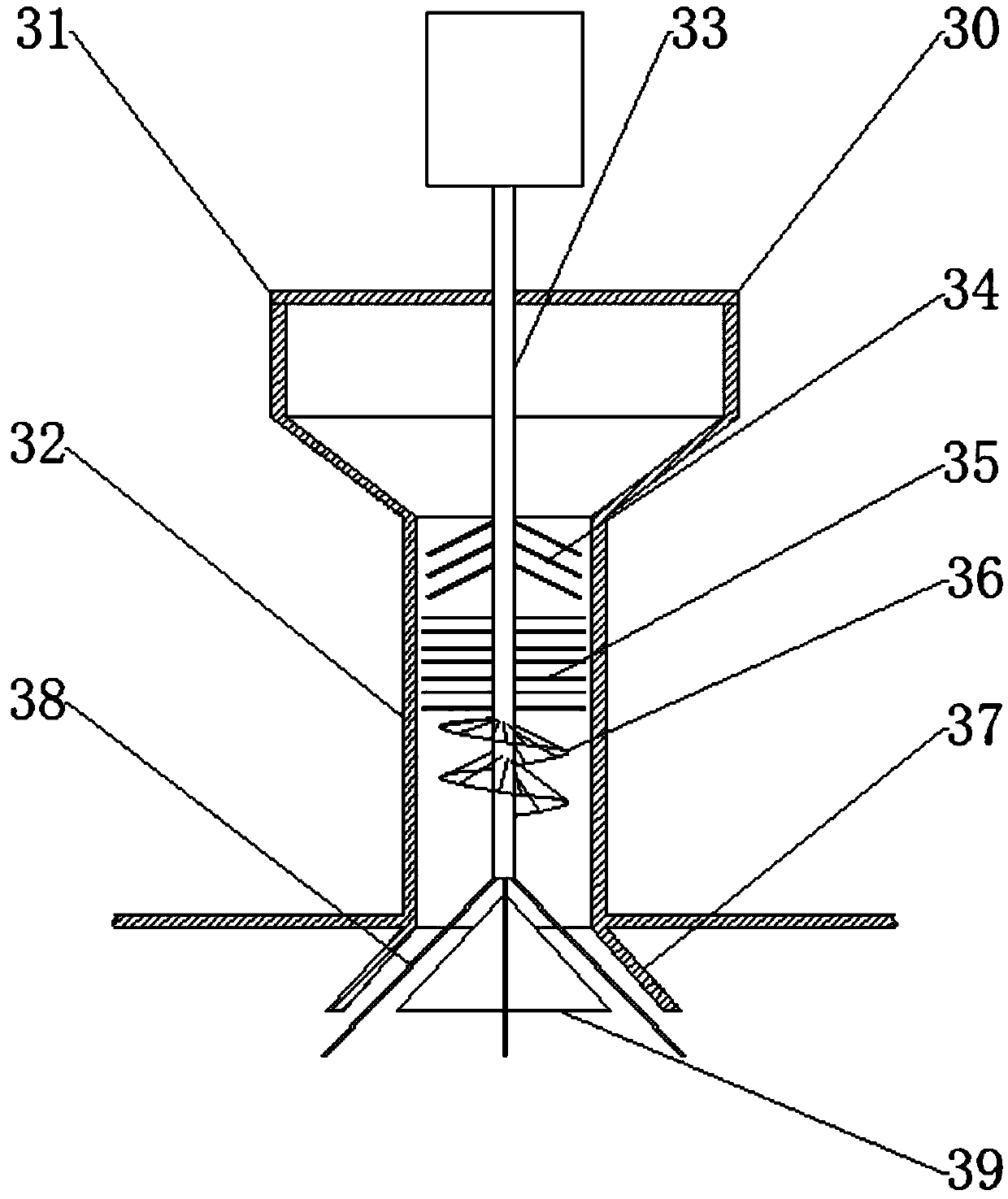

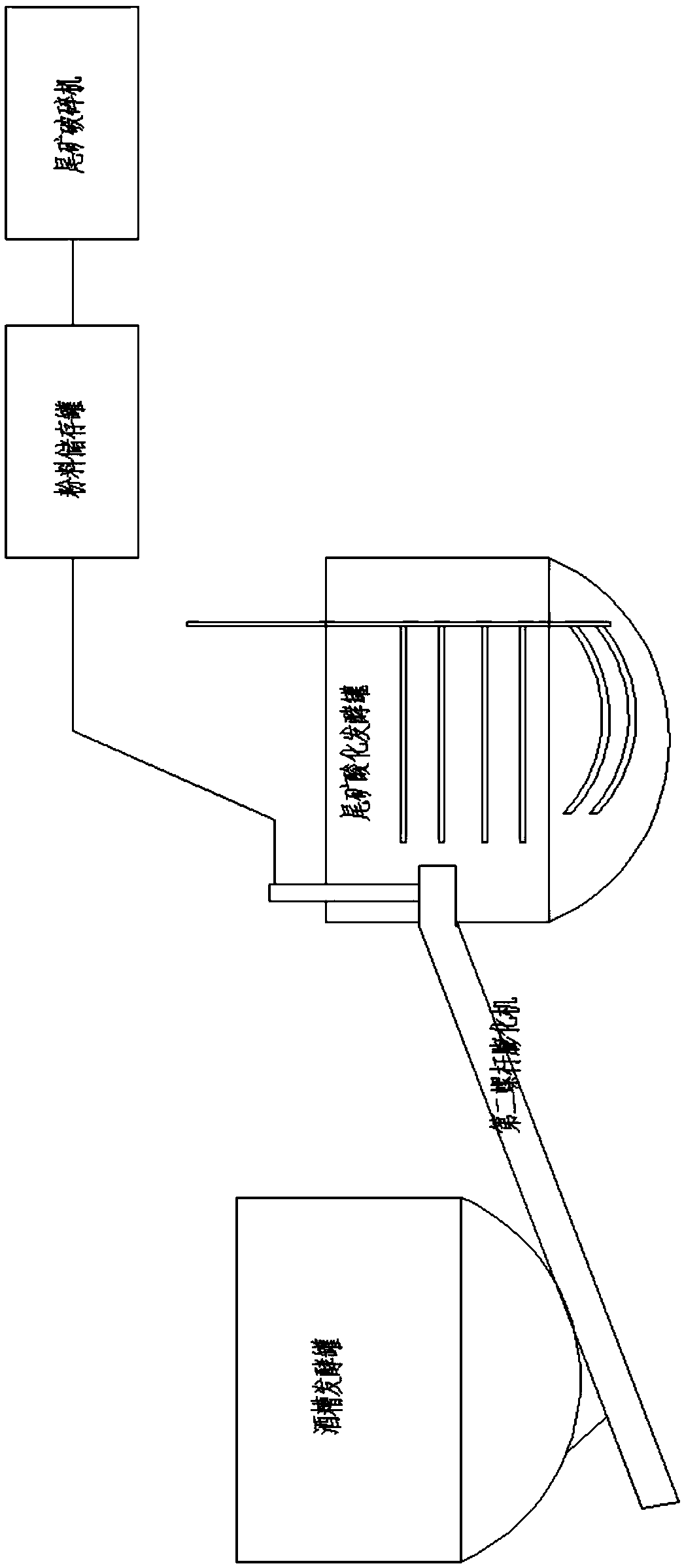

[0042] Such as Figures 1 to 3 As shown, a microorganism-mediated production process and system of distiller's grains, straw, and coal gangue whole-element bio-organic fertilizer, such as figure 1 shown, including the following steps:

[0043] 1. Straw treatment process

[0044] 1) Use a straw crusher to break the straw into short rods with a length of 1-3cm;

[0045] 2) adjusting the moisture content of the crushed straw to 15-23%;

[0046] 3) Crushing the straw obtained in step 2) again.

[0047] 4) The purpose of re-crushing is to speed up the rate of cellulose decomposition in the straw. The re-crushing method can be chosen to use a crusher, or through a screw extruder, and control the maximum temperature in the screw extruder to 105 through water cooling or air cooling. Within the range of -115 degrees Celsius; the biggest difficulty in the utilization of straw lie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com