Non destructive detection method of anchor rod ultimate bearing capacity

A technology of ultimate bearing capacity and non-destructive testing, which is applied in the direction of complex mathematical operations, instruments, and analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

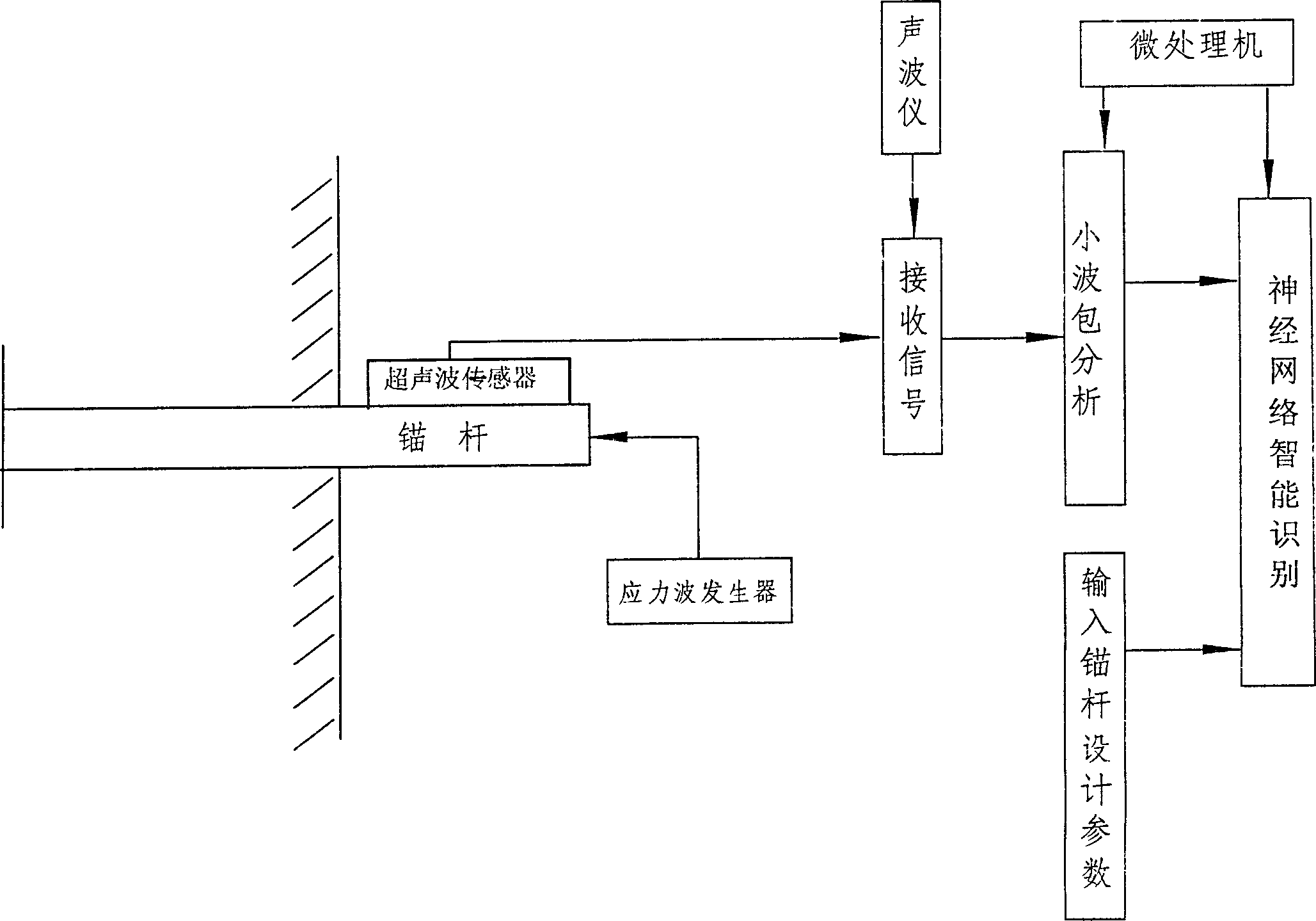

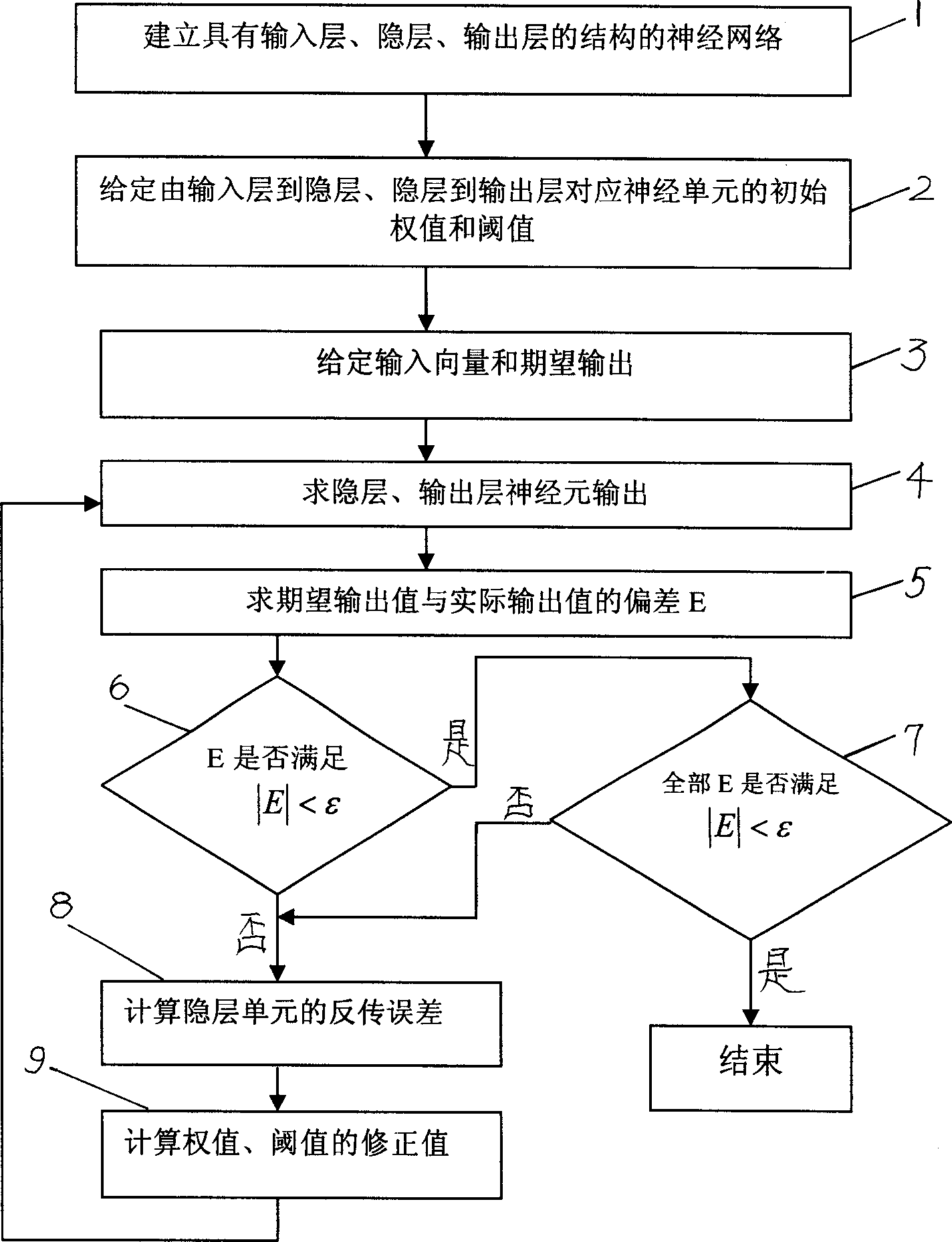

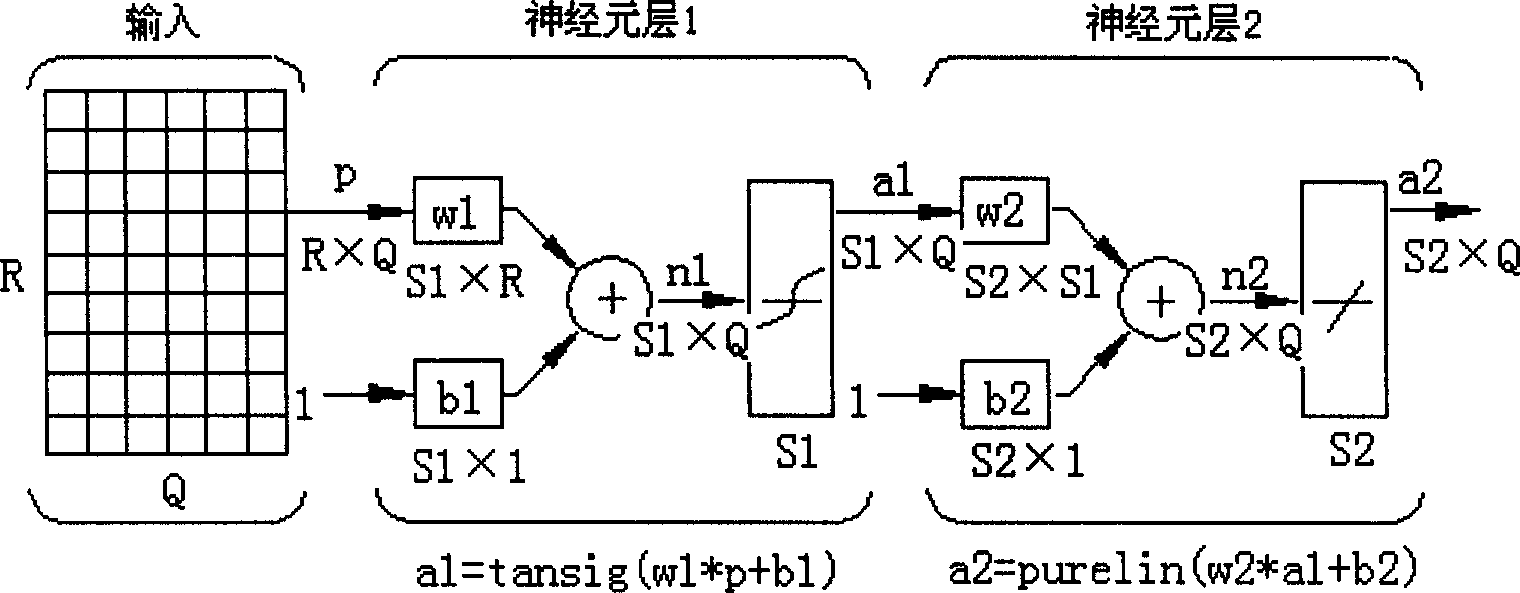

[0047] see figure 1 , a non-destructive testing method for the ultimate bearing capacity of anchor bolts, characterized in that: it uses structural dynamic measurement technology to obtain information, uses intelligent signal analysis technology to process the obtained information, and then uses the trained neural network intelligent recognition system A detection method for identifying the ultimate bearing capacity of a bolt is carried out.

[0048] The method specifically includes the following steps:

[0049] (1) The stress wave generator is excited to generate an acoustic wave signal that acts on the top of the bolt to be detected;

[0050] (2) The ultrasonic sensor obtains the sound wave measurement signal reflected by the bottom of the bolt, and transmits the signal to the signal receiving device;

[0051](3), the signal receiving device transmits the signal to the microprocessor for wavelet packet analysis to extract the energy feature vector;

[0052] (4) The proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com