Cut processing method, cut processing apparatus and work-piece supporting construction used with said apparatus

A technology for cutting processing and workpieces, which is applied in the direction of shearing devices, metal processing, metal processing equipment, etc., and can solve the problems of improving cutting accuracy, not being able to cut with high precision, and gaps in workpiece clamping thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

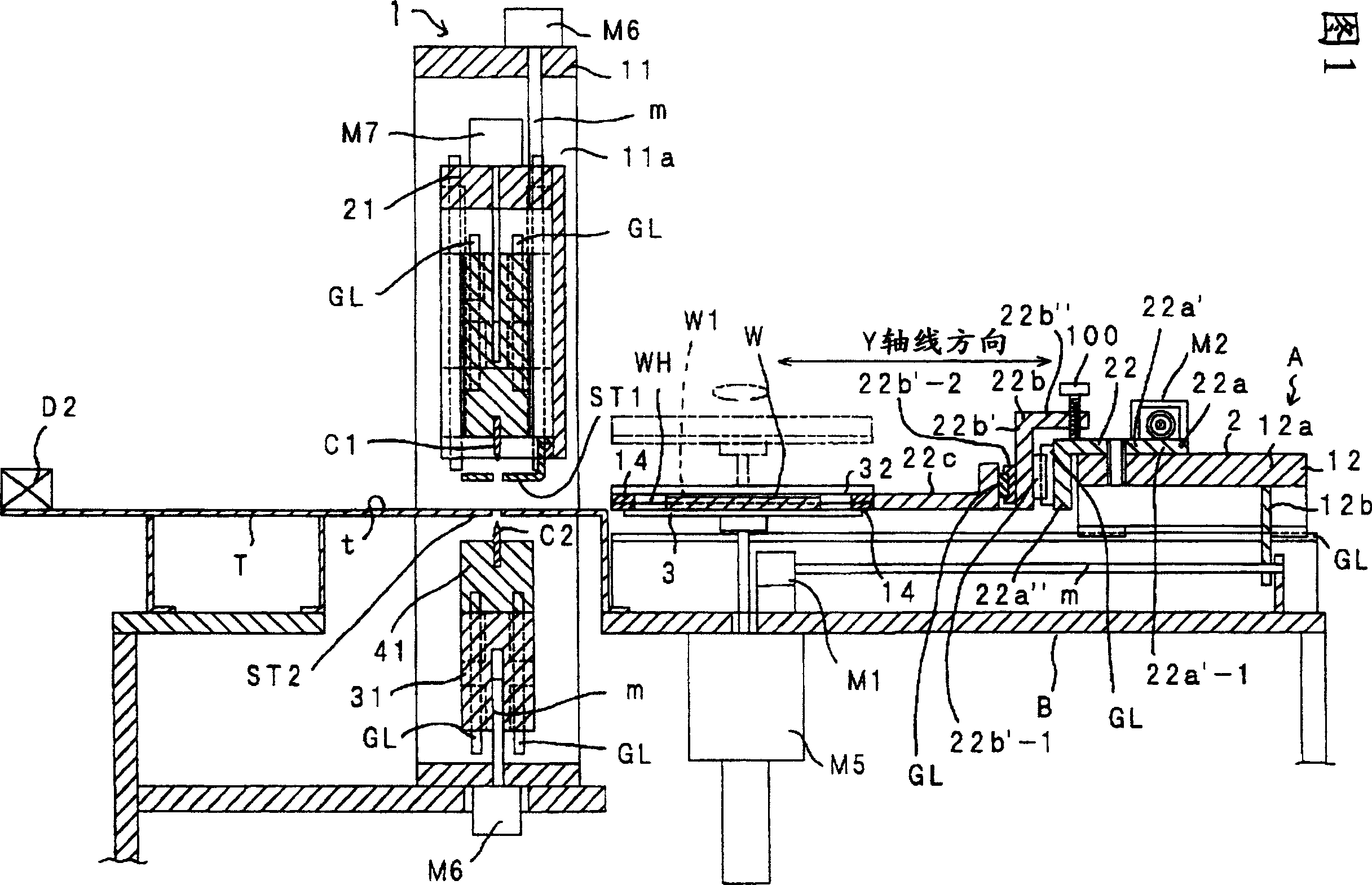

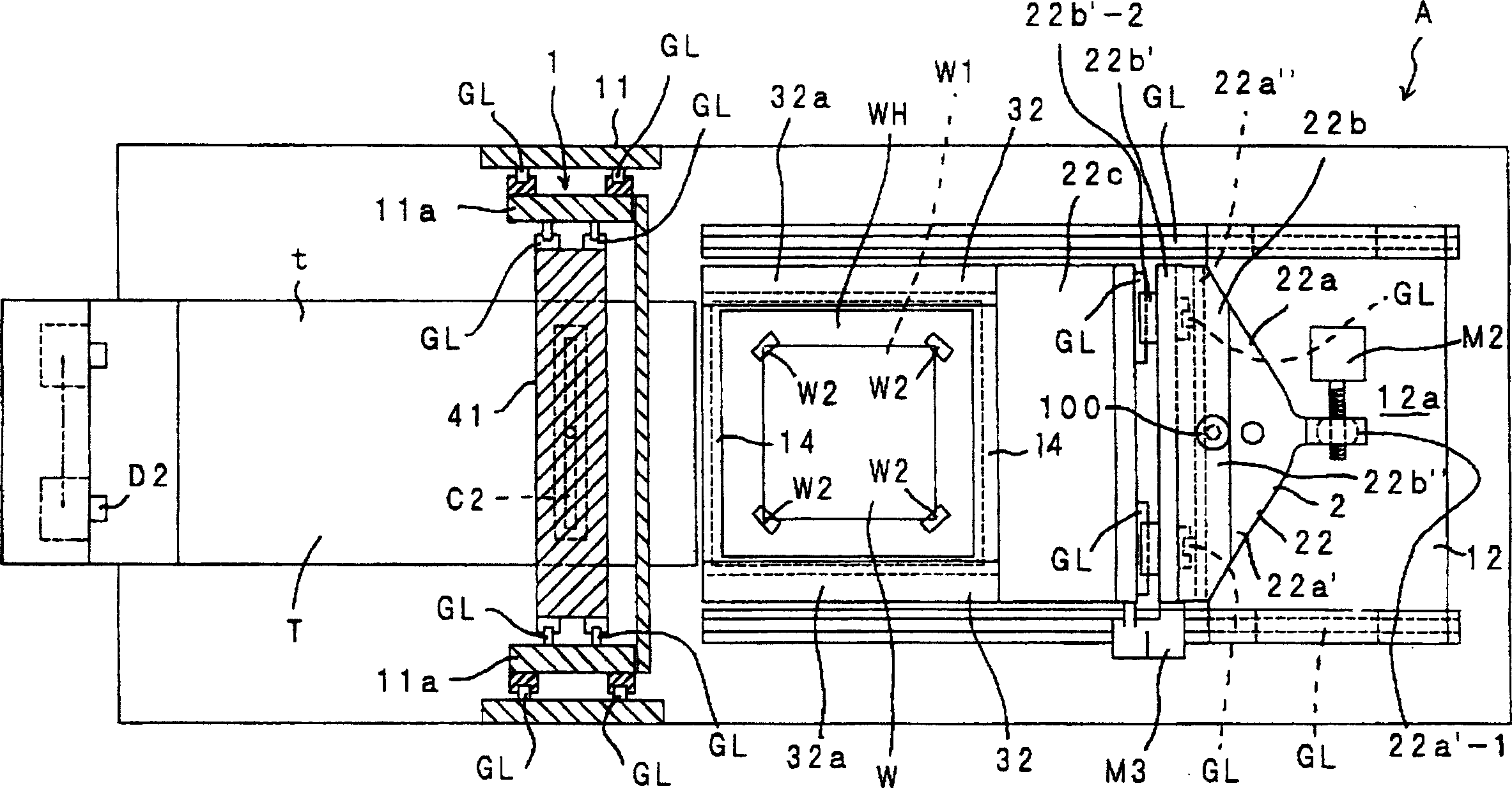

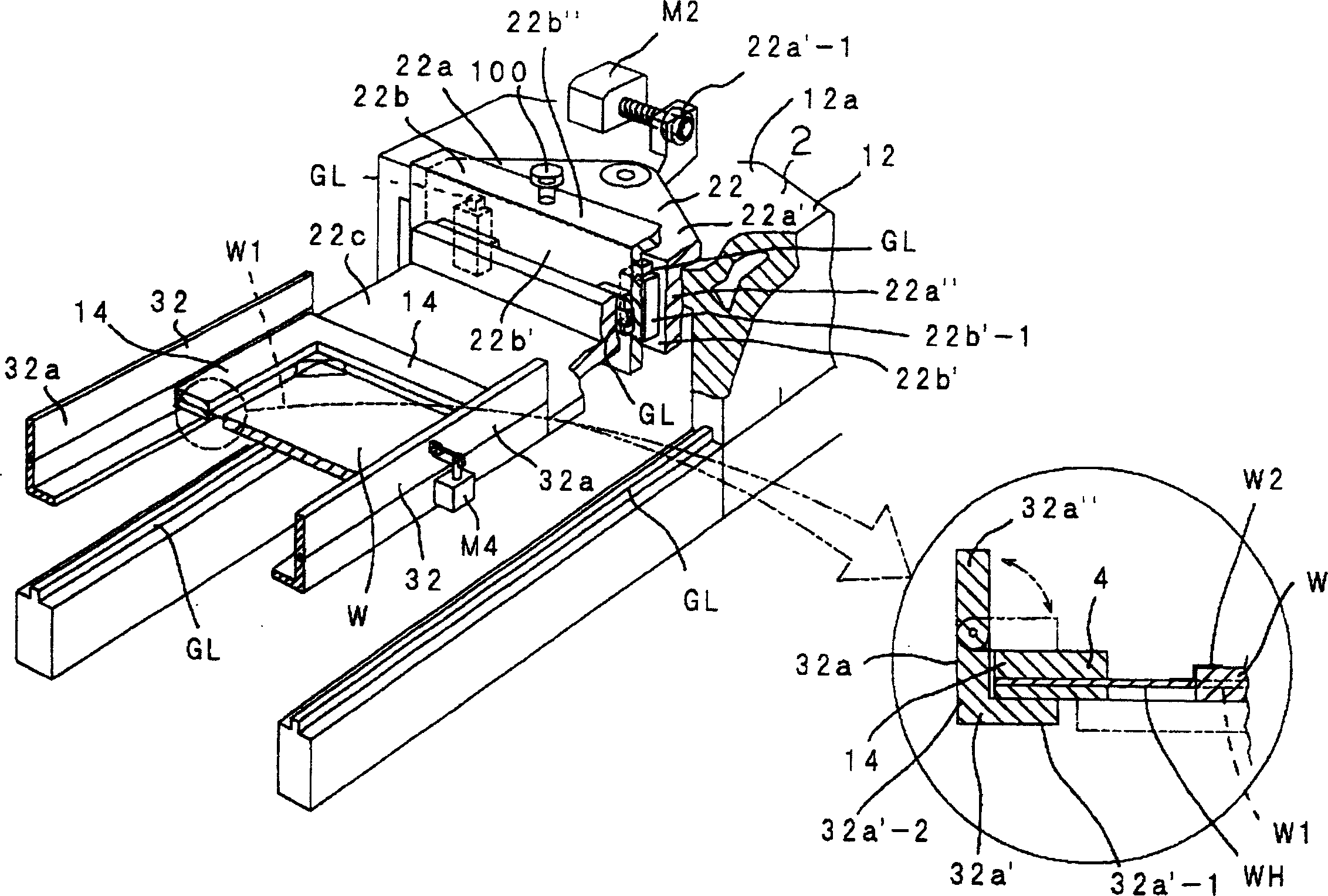

[0089] Cutting processing device A is, as shown in Figure 1, figure 2 , Figure 4 , Figure 5 As shown, on the front side of the Y-axis direction of the support table B, a cutting machine 1 and a table T with the table t as the reference plane will be installed, and the moving device 2 that can release the clamping workpiece W will be placed on the support table B in the YX-axis direction. The control is operable and set so that it can be corrected in the θ direction, and the indexing table is set at the standby position of the moving device 2 .

[0090] Above-mentioned support platform B is, as shown in Figure 1~ image 3 As mentioned above, the guide rail GL arranged parallel to the direction of the cutting machine is used to make the moving device 2 move controllably in the direction of the Y axis.

[0091] The above-mentioned mobile device 2 is, for example, figure 2 , image 3 As shown, the door-shaped body 12 slidably engaged on the above-mentioned guide rail GL and...

Embodiment 2

[0126] Second, according to Figure 9 A second embodiment of the cutting device for performing the cutting method will be described. The clamper 32 of this embodiment is capable of releasing the clamping of the frame body 14 front and rear in the Y-axis direction by the edge member 14 .

[0127] The holder 32, in detail, on the above-mentioned fastener supporting body 22c, forms the parallel constituent pieces 32b' in the respective Y-axis directions into a flat plate shape, and forms the constituent pieces 32b' connecting the two ends of the constituent pieces 32b' into an L shape. The rectangular frame 32b of the rectangular frame 32b is arranged continuously toward the direction of the cutting machine, and the side on which the rotating body 32a is pivoted on the front and rear forming pieces 32b' corresponds to the horizontal section 32b"-1 of the forming piece 32b', and the horizontal piece part 32 is accommodated. The concave part 14a of "-1 lies in the above-mentioned f...

Embodiment 3

[0131] Second, according to Figure 10 A third embodiment of a cutting device for carrying out a cutting method will be described, and this embodiment shows a modified example of the workpiece support structure.

[0132] In this embodiment, the workpiece holding plate WH is made of a synthetic resin material that allows elastic deformation.

[0133] As such, when the workpiece clamping plate WH is made of a synthetic resin material that allows elastic deformation, even if the back of the workpiece W is not in full-width sliding contact with the table t due to the elastic deformation function, the workpiece W can be elastically deformed by its own weight. It can be slidably contacted with the table surface t, and the mounting position of the workpiece WH to the workpiece W by the workpiece clamping plate WH does not require high precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com