Sewage treatment device and sewage treatment method with diatomite as flocculation core

A sewage treatment device, diatomite technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of raw water quality fluctuation, organic pollutants that are difficult to degrade, and unsatisfactory, etc., and achieve high quality of effluent water , high processing efficiency, and the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

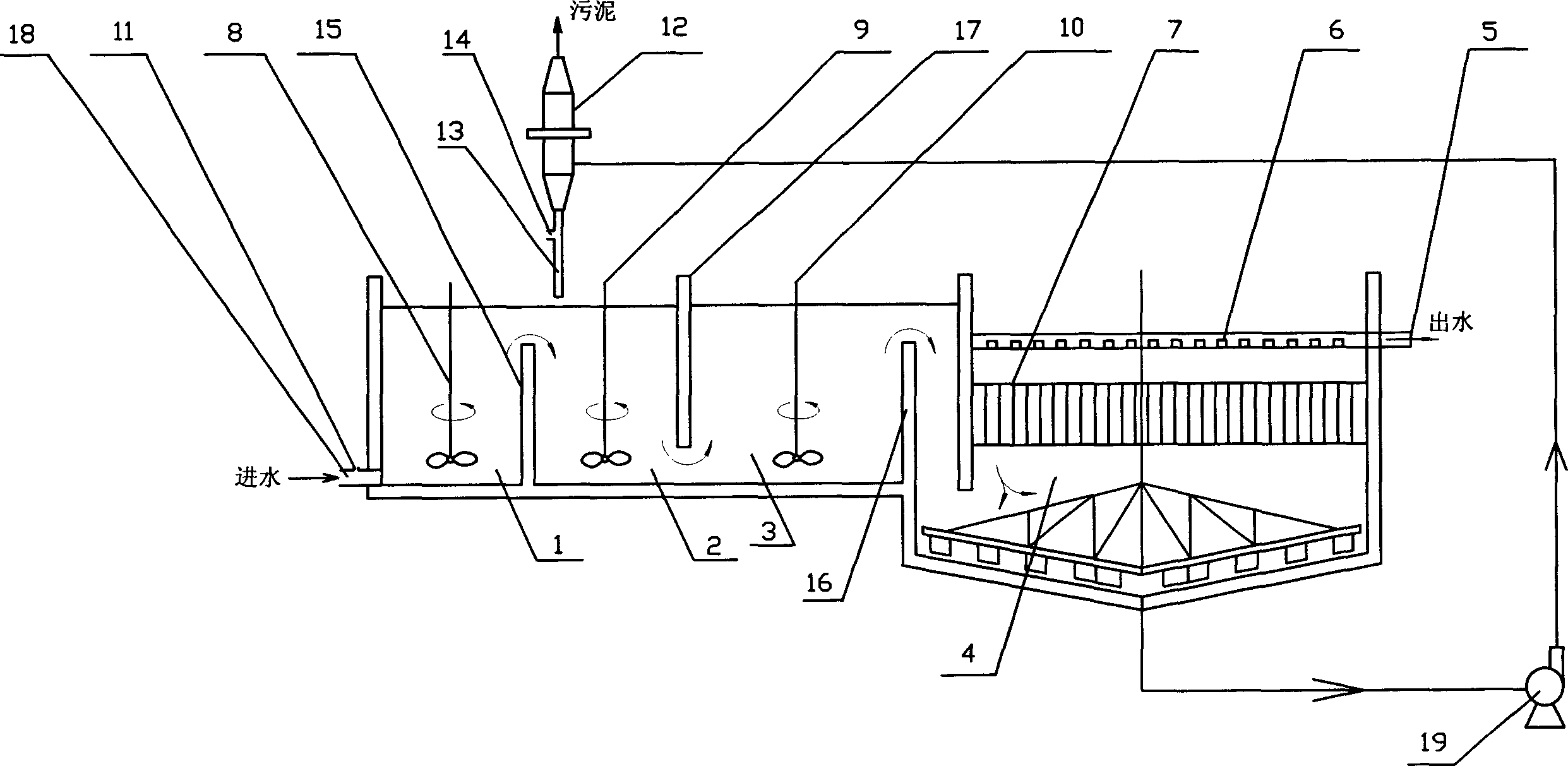

[0036] (1) Add coagulant at the coagulant dosing port, then add water at the water inlet, and stir with the stirring paddle of the coagulation tank;

[0037] (2) inject the flocculation core body and the flocculant together from the flocculant dosing port into the gravity intensified tank, and accelerate the formation of flocs through the agitation of the gravity intensified tank and the stirring paddle in the mature tank;

[0038] The flocculation core body has a density of 1.1g / cm 3 diatomite; the total dosage of flocculation core body and flocculant is 15mg / L (relative to the sewage to be treated), and the ratio of flocculant to flocculation core body is 1 / 10; diatomite has a microporous structure and Huge specific surface area, the pore volume of diatomaceous earth is 1.0cm 3 / g, the specific surface area is 21m 2 / g, the hole radius is 2000 Å;

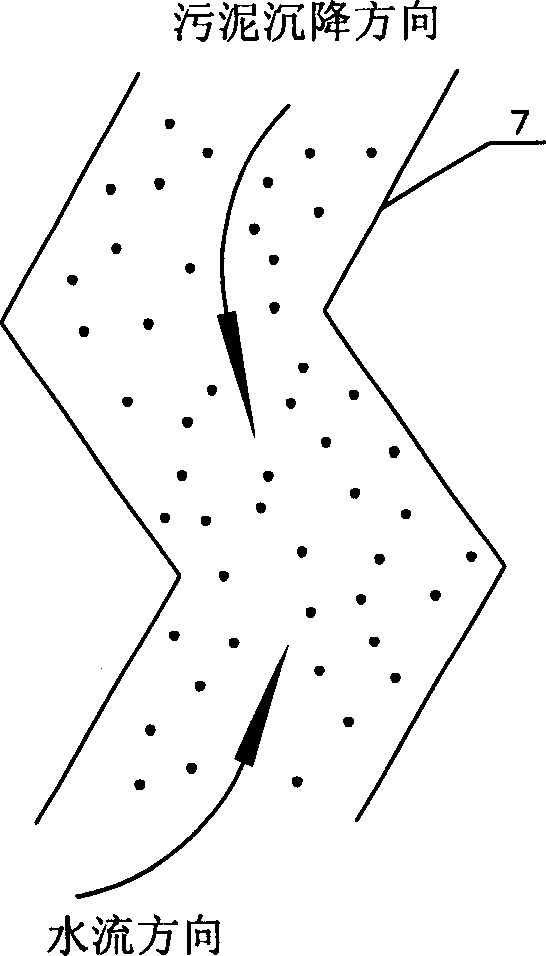

[0039] (3) In the inclined plate clarification tank, the flocculation core body adhering to a large amount of suspended matte...

Embodiment 2

[0041] (1) Add coagulant at the coagulant dosing port, then add water at the water inlet, and stir with the stirring paddle of the coagulation tank;

[0042] (2) inject the flocculation core body and the flocculant together from the flocculant dosing port into the gravity intensified tank, and accelerate the formation of flocs through the agitation of the gravity intensified tank and the stirring paddle in the mature tank;

[0043] The flocculation core body has a density of 1.5g / cm 3 diatomite; the total dosage of flocculation core body and flocculant is 10mg / L (relative to the sewage to be treated), and the ratio of flocculant to flocculation core body is 1 / 15; diatomite has a microporous structure and Huge specific surface area, the pore volume of diatomaceous earth is 0.4cm 3 / g, the specific surface area is 19m 2 / g, the hole radius is 500 Å;

[0044] (3) In the inclined plate clarification tank, the flocculation core body adhering to a large amount of suspended matter i...

Embodiment 3

[0046] (1) Add coagulant at the coagulant dosing port, then add water at the water inlet, and stir with the stirring paddle of the coagulation tank;

[0047] (2) inject the flocculation core body and the flocculant together from the flocculant dosing port into the gravity intensified tank, and accelerate the formation of flocs through the agitation of the gravity intensified tank and the stirring paddle in the mature tank;

[0048] The flocculation core body has a density of 1.3g / cm 3 diatomite; the total dosage of flocculation core body and flocculant is 20mg / L (relative to the sewage to be treated), and the ratio of flocculant to flocculation core body is 1 / 5; diatomite has a microporous structure and Huge specific surface area, the pore volume of diatomaceous earth is 1.4cm 3 / g, the specific surface area is 25m 2 / g, the hole radius is 8000 Å;

[0049] (3) In the inclined plate clarification tank, the flocculation core body adhering to a large amount of suspended matter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com