Ultrasonic time-of-flight diffraction detection method based on synthetic aperture focusing technique

A technology for synthetic aperture focusing and detection methods, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, special data processing applications, instruments, etc., and can solve problems such as inability to accurately locate and quantify plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

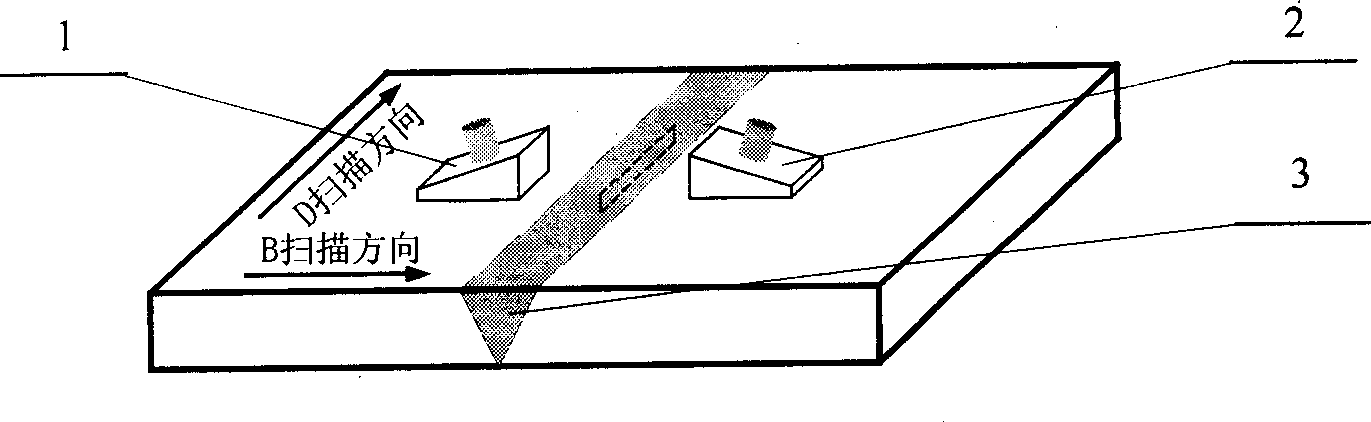

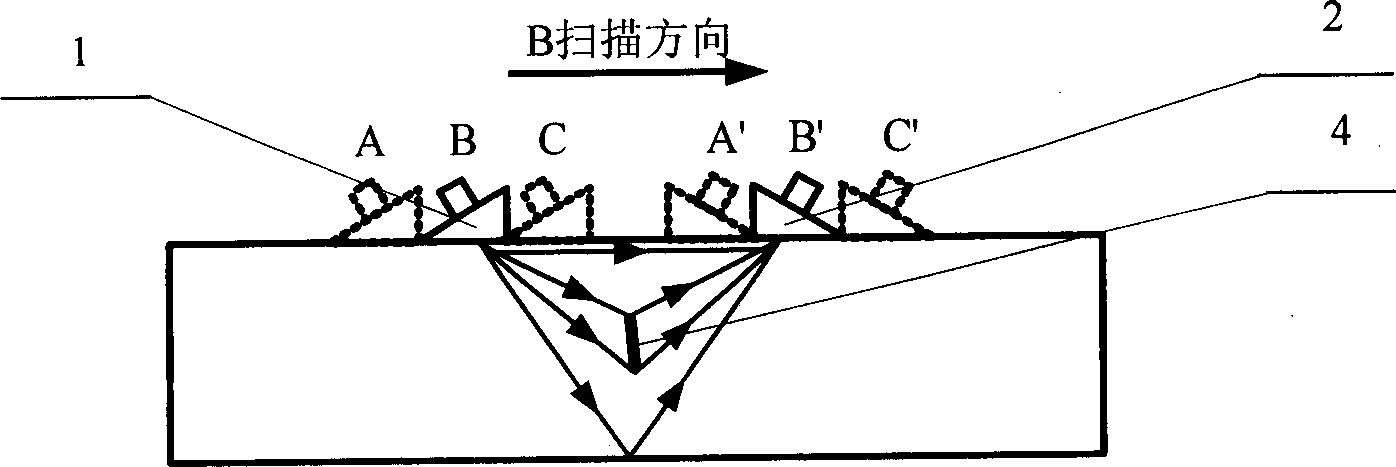

[0030] Specific implementation mode one: see Figure 1 to Figure 8 In this specific embodiment, the detection method of the present invention is described by taking internal buried defects as an example. This specific embodiment is to detect the internal buried defects processed on the aluminum alloy plate with a thickness of 20mm, and the detection steps are as follows:

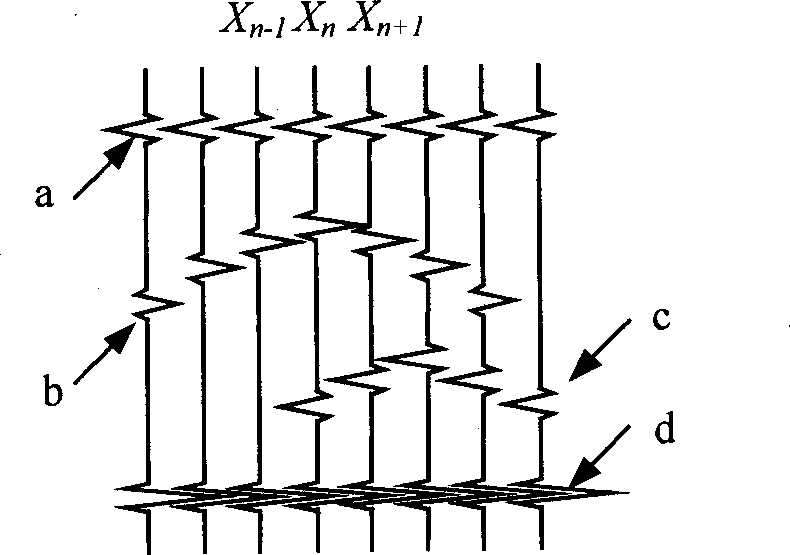

[0031] The first step is to first place the area to be inspected of the plate and its structural weld between the transmitting probe and the receiving probe, and first perform a D scan on the inspected area to determine the approximate location of the defect; set the scan step of the probe, Carry out a B-scan over the defect, and the detection system will receive the detection data of the probe to generate the original B-scan image to be processed, such as Image 6 As shown; where, the lateral wave propagating along the shallower depth below the surface of the plate and structural weld corresponds to the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com