Field emission display device in separated structure

A field emission and display device technology, used in image/graphic display tubes, instruments, optics, etc., can solve the problems of complex preparation process, restrict the promotion and application of surface conduction electron emission display, and achieve the effect of reducing technology and technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

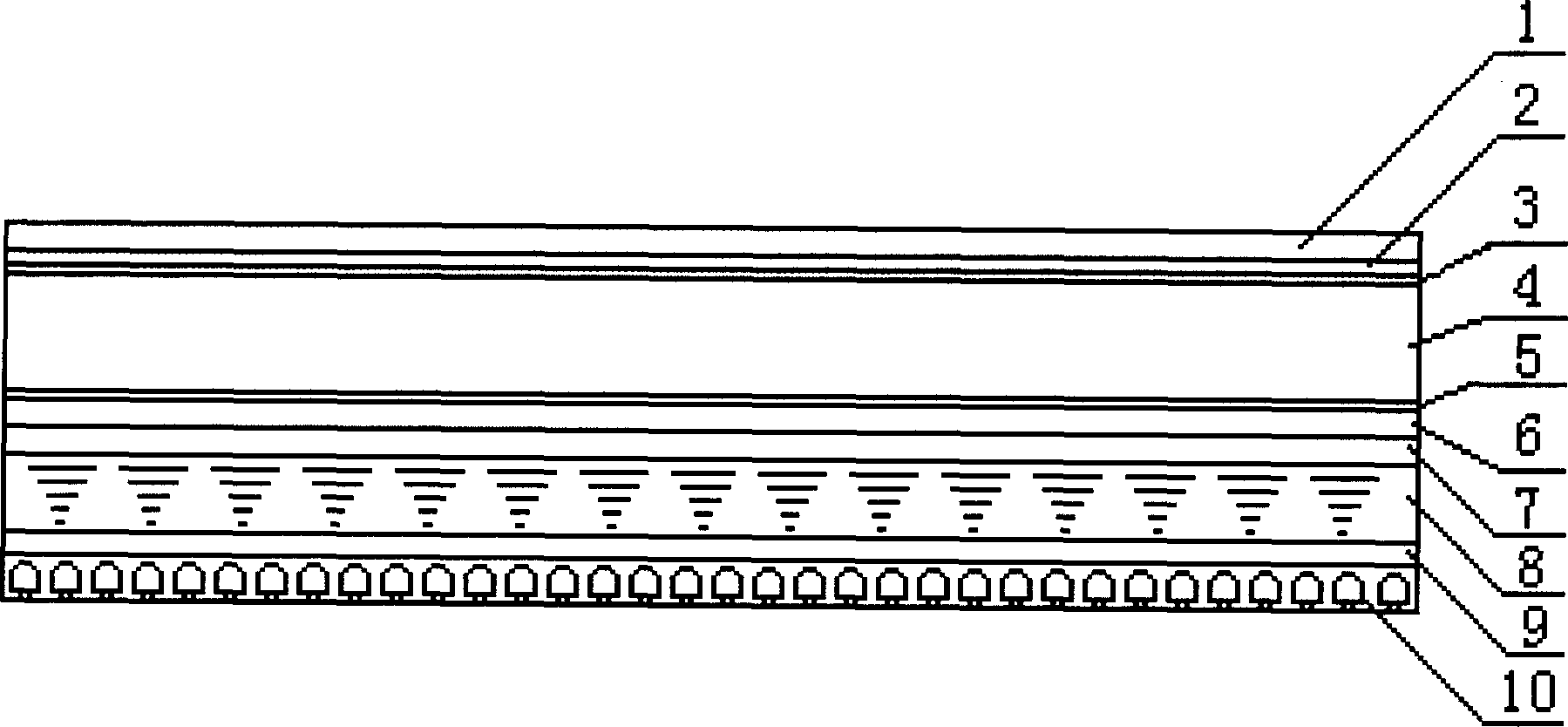

[0010] Referring to the accompanying drawings, the present invention includes a glass substrate 1 and a trichromatic phosphor array 2 arranged on the inner surface of the glass substrate 1 and an aluminum film 3 with a thickness of 1 to 1000 nanometers, and an ITO glass substrate 6 is arranged at the lower end of the glass substrate 1 A vacuum chamber 4 with a thickness of 1 to 6 mm is formed between the glass substrate 1 and the ITO glass substrate 6. The aluminum film 3 and the ITO glass substrate 6 are respectively connected to the positive and negative poles of DC high voltage, and the ITO glass substrate 6 is also evaporated. There is a photocathode array 5, and the positions of the photocathode array 5 and the trichromatic phosphor array 2 correspond one by one, and the lower side of the ITO glass substrate 6 is provided with an upper ITO glass substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com