Automatic rotary plastic bottle blowing machine

A fully automatic blow molding machine technology, applied in the field of processing equipment for hollow plastic containers, can solve the problems of low production efficiency, difficult control, troublesome installation and transportation, etc., and achieve the effects of fast production speed, simple structure and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

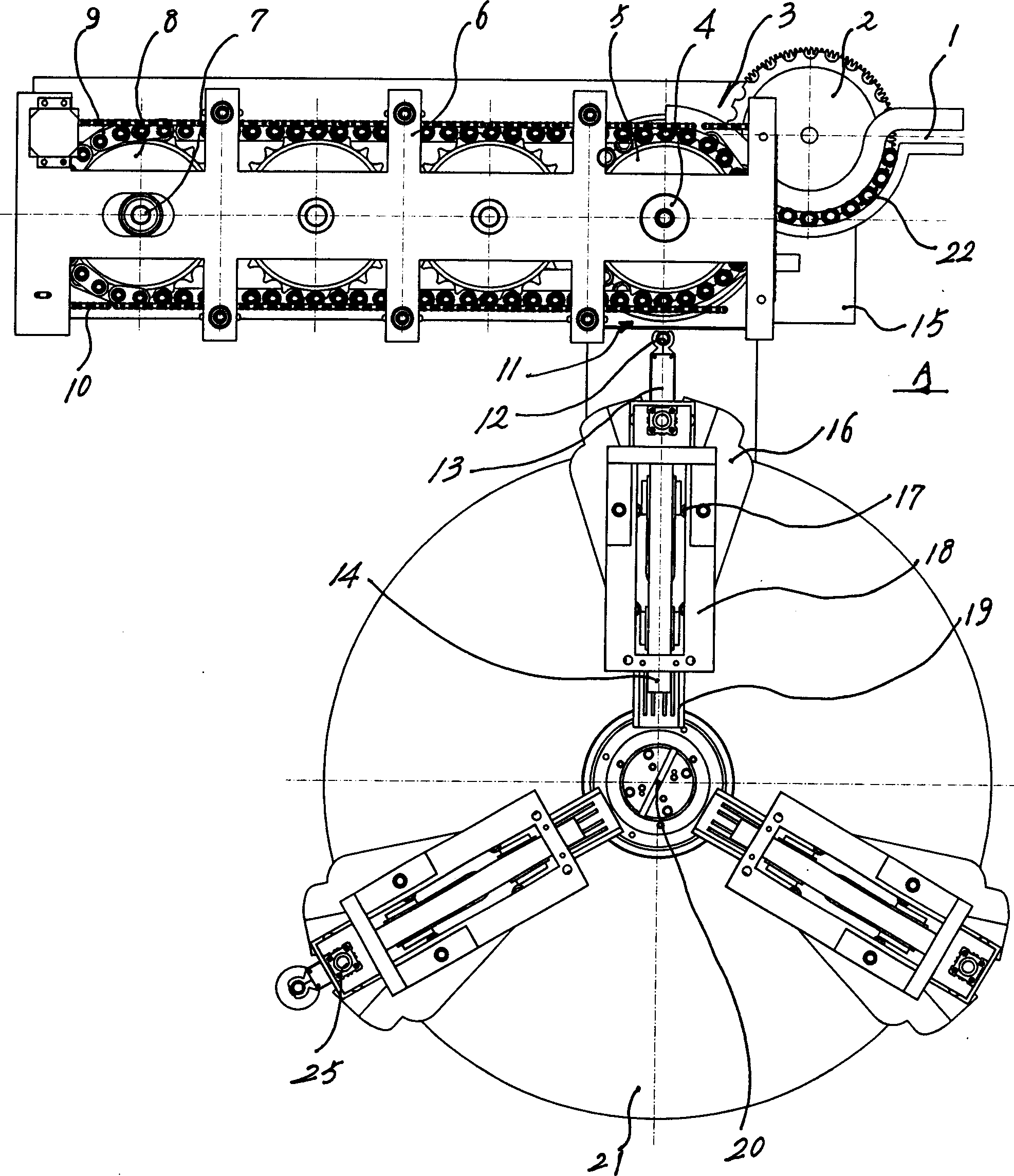

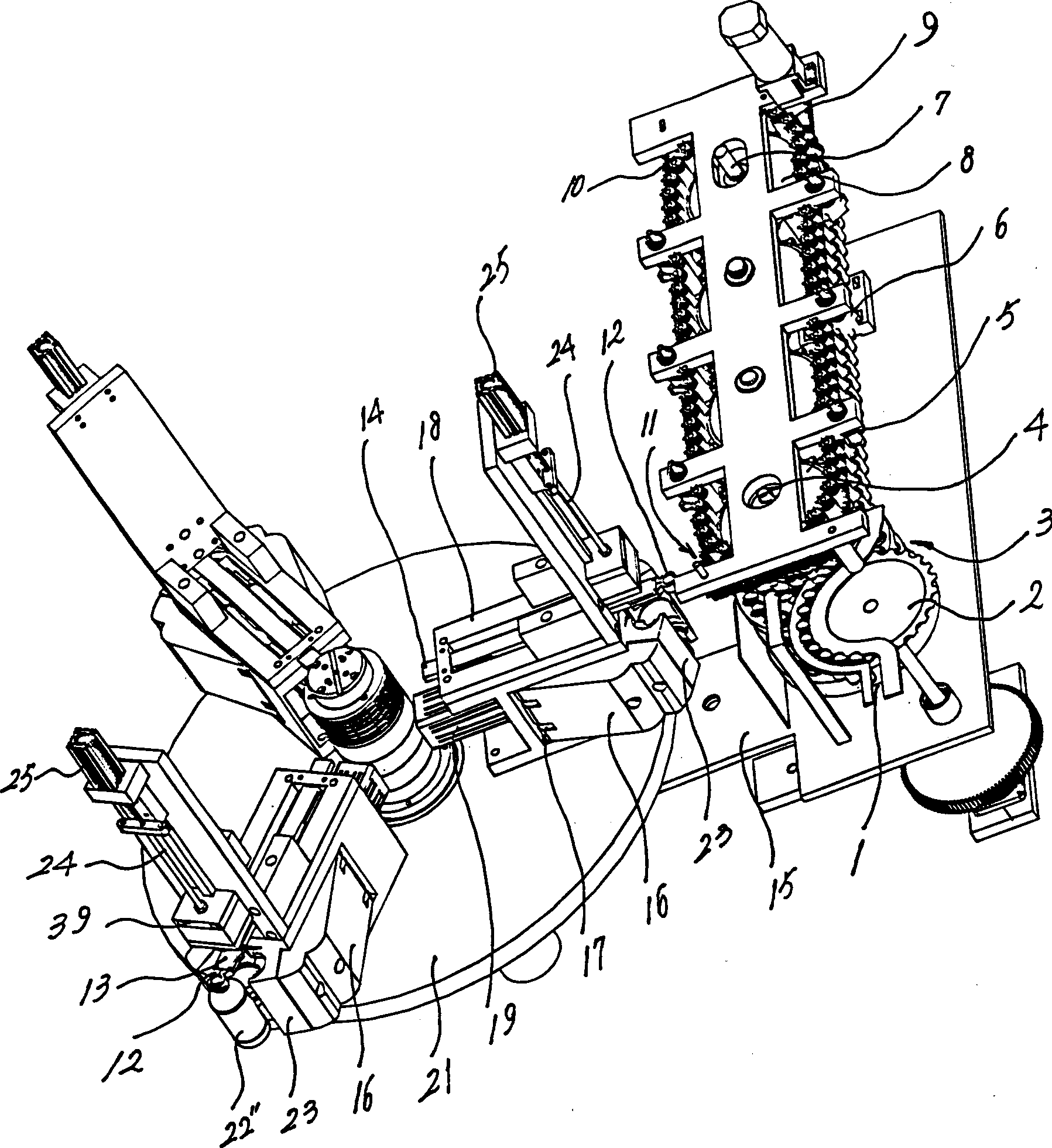

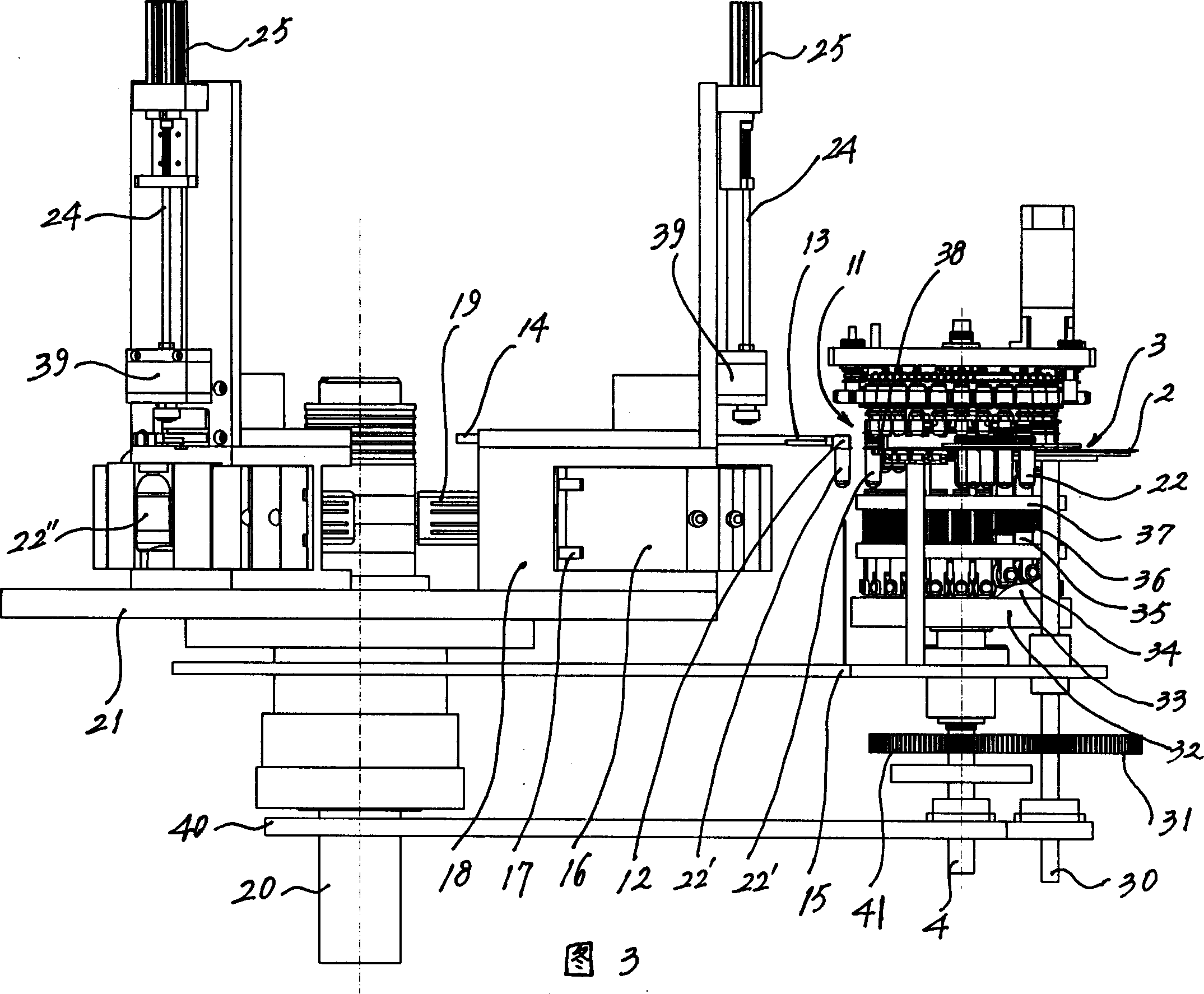

[0010] The invention discloses a rotary direct-taking full-automatic plastic bottle blowing machine, which can be divided into two parts: a heating device for plastic bottle tubes and a bottle blowing mechanism for stretch blow molding. Mechanism and feeding mechanism, the basic structure of the heating device is as follows figure 1 , figure 2 As shown in Fig. 3, the driving shaft 4 drives the driving sprocket 5, drives the driven sprocket 8 through the chain 9, the driven sprocket has the driven shaft 7, and there is a bottle tube supporting pipe in the chain, and a heating device for installation is arranged. Support 6, can make the rotation chain 10 etc. of supporting pipe tool rotation, but the specific type of heating device has various structures, and this technical scheme is owing to can adopt multi-station, and production efficiency is high, and the speed of requiring heating is also fast, so The heater can be multiple back and forth heating channels (attached figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com