Making process of 3D color object

A technology of three-dimensional objects and production methods, which is applied in the fields of manufacturing tools, decorative arts, ceramic molding machines, etc., can solve the problems of high production cost, slow speed, and single-color three-dimensional solids, and achieves low cost, high speed, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1. The method of making a color three-dimensional object, the steps are as follows:

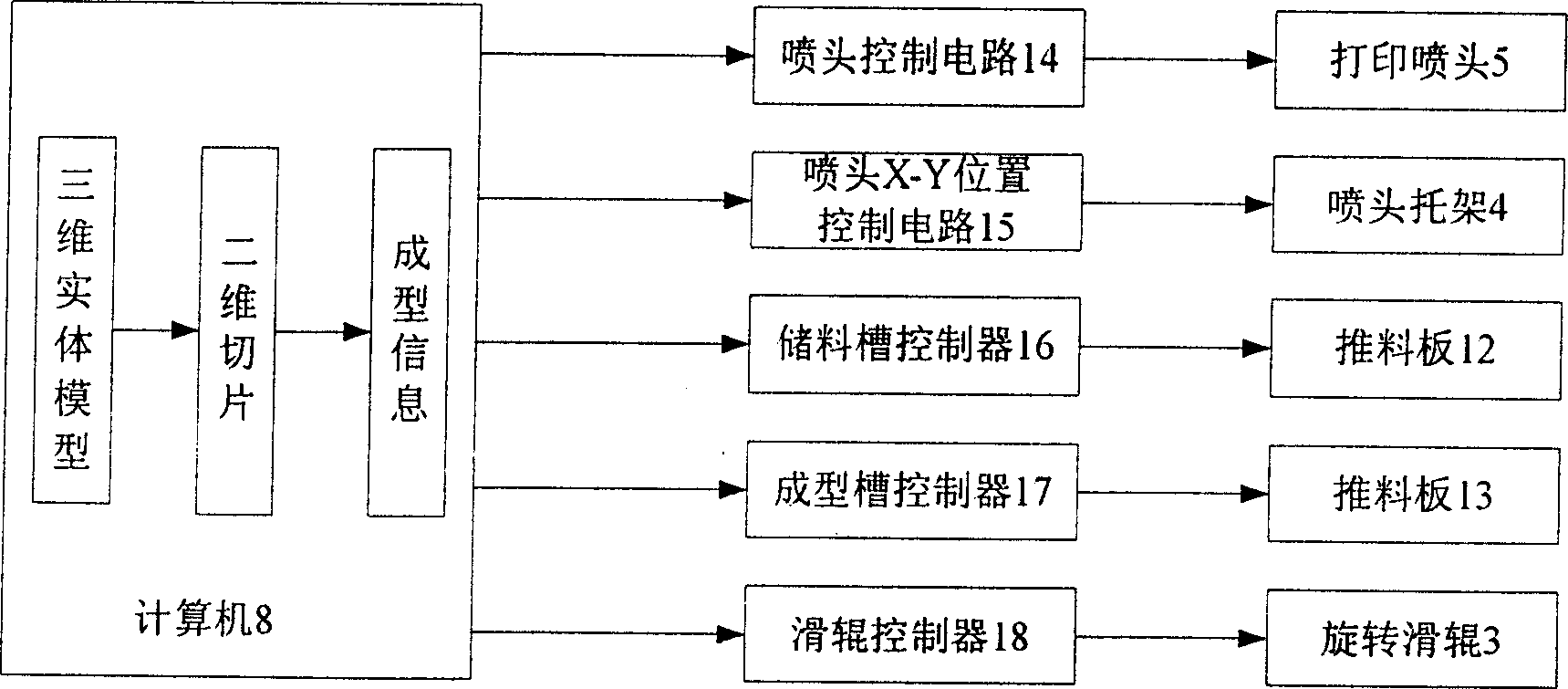

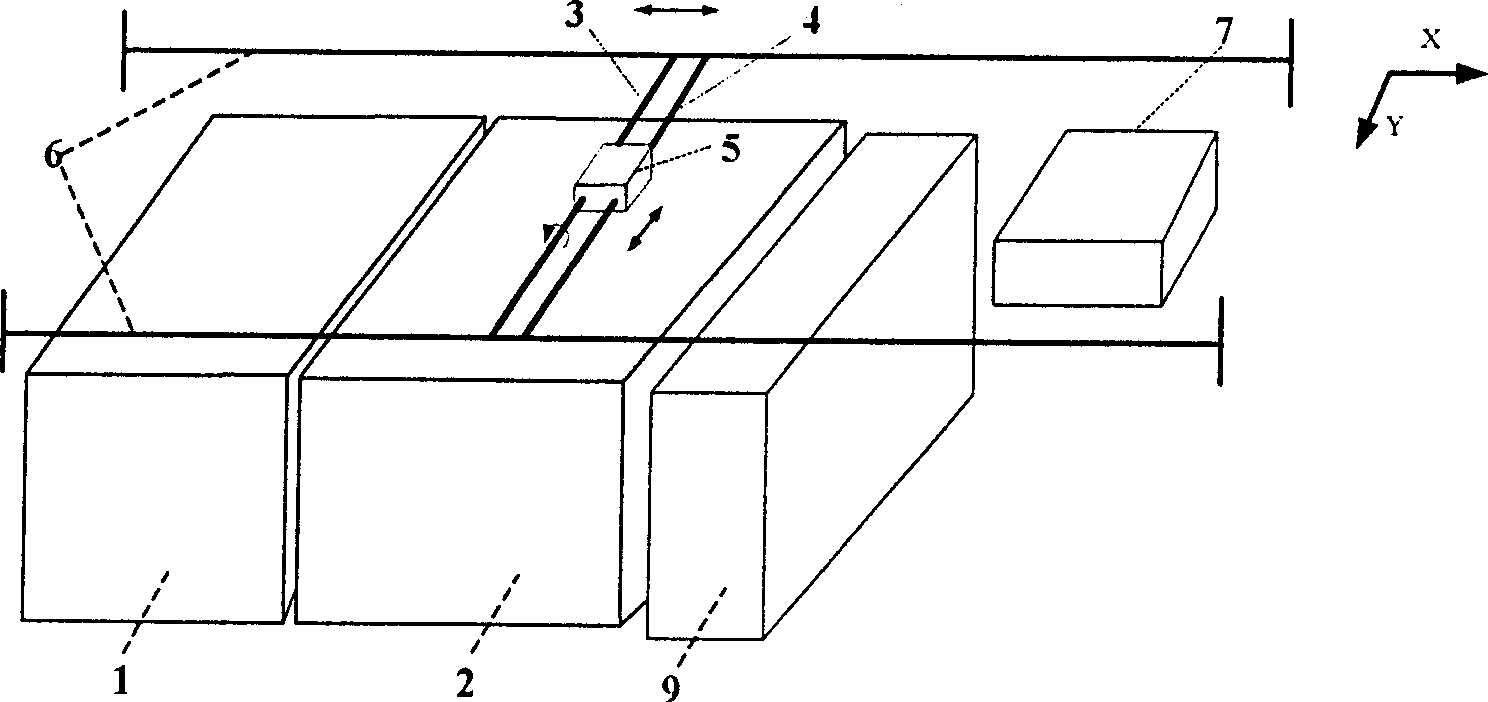

[0027] a. Establish a computer entity model of a three-dimensional object, slice and layer it, and take out the forming information of each layer;

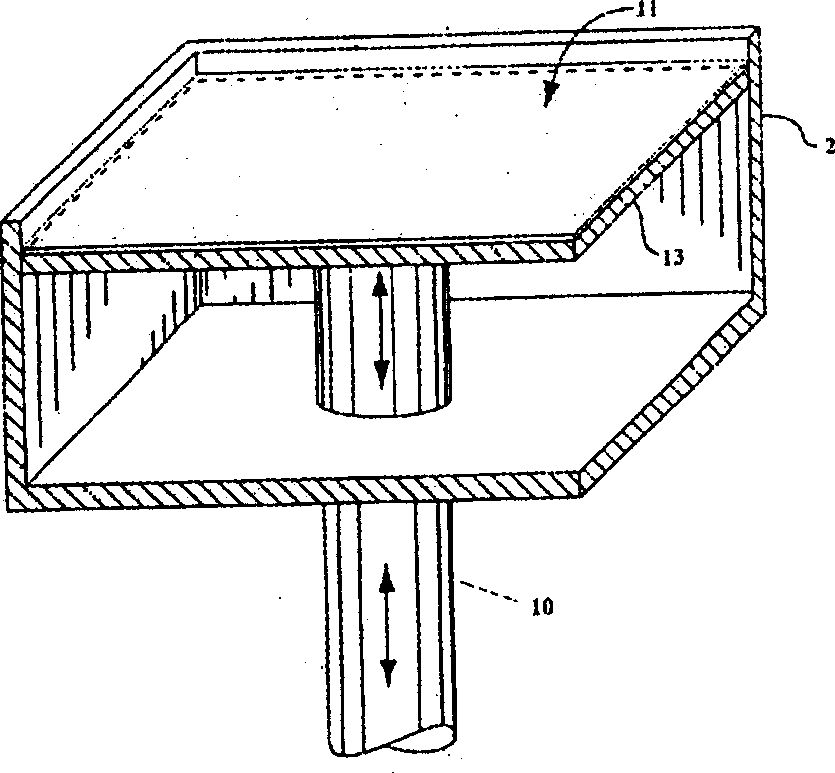

[0028] b. Add magenta, cyan, and yellow pigments to the water to make four water-soluble liquids with different colors, namely, colorless liquid without pigment, liquid with magenta pigment, liquid with cyan pigment, and Yellow pigment liquid; the computer controls the print nozzle to make the set printing movement according to the forming information of the first layer and selectively spray the water-soluble liquid on the flattened gypsum powder layer according to the forming information requirements. The particle size of the powder is 5μm, the thickness of the powder is 0.02mm, and the penetration depth when spraying water-soluble liquid is 105% of the thickness of the layer. The water-soluble liquid quickly hydrates with the powd...

Embodiment 2

[0033] Example 2 is basically the same as Example 1, except that the water-soluble liquid is made by adding six kinds of pigments: magenta, cyan, yellow, red, blue, and green to the water, and the six kinds of pigments with different colors are made. Water-soluble liquid; using starch powder, the particle size of the powder is 100μm, the powder is mixed with fine fibers of 30μm in length, the thickness of each layer of powder is 0.1mm, and the penetration depth when spraying the water-soluble liquid is the thickness of the layer 140%.

Embodiment 3

[0034] Example 3 is basically the same as Example 2. The difference is that the particle size of the powder is 300μm, and the powder is mixed with fine fibers with a length of 60μm. The thickness of each layer of powder is 0.5mm. The penetration depth is 180% of the thickness of the layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com