Prepn process of acyldhydrazino adipate with free hydrazine content lower than 10ppm

A technology of adipate dihydrazide and dimethyl adipate, applied in the preparation of hydrazide, organic chemistry, etc., can solve the problems of human and environmental hazards, difficult to remove and clean, and achieve the effect of low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

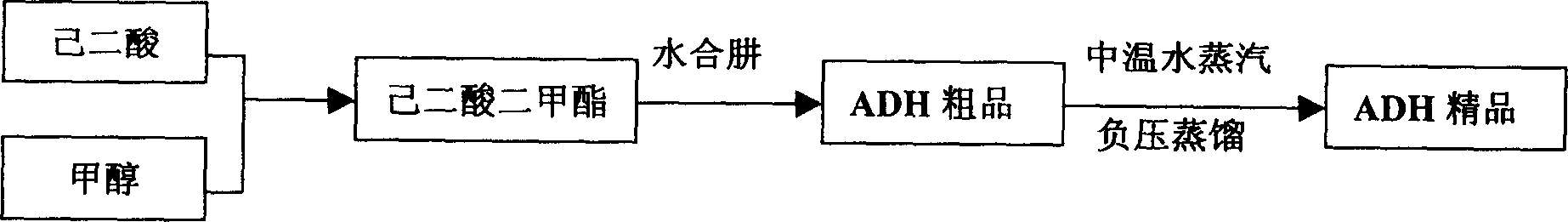

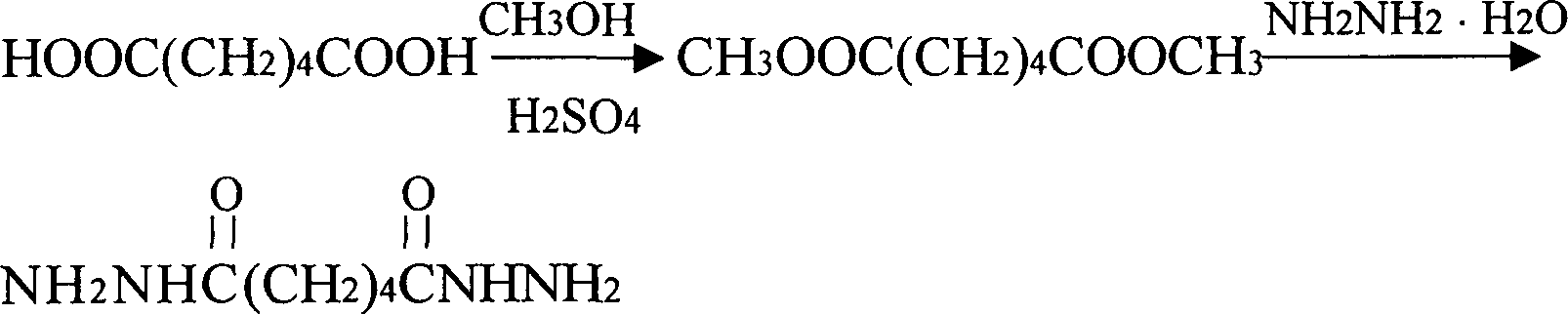

[0014] The present invention uses adipic acid and methanol as raw materials, first obtains dimethyl adipate according to the existing synthesis technology, and then synthesizes it with hydrazine hydrate to obtain the crude product of adipic acid dihydrazide, and the crude product of adipic acid dihydrazide in the Distilled with medium-temperature steam under negative pressure conditions to obtain adipic acid dihydrazide refined product, the main content of which is greater than or equal to 99.0%, the content of free hydrazine is less than or equal to 10ppm, the distillation temperature is controlled at 60 ° C ~ 65 ° C, and the vacuum degree is 0.095 MPa Distillation time 6 hours.

[0015] The specific preparation method is as follows:

[0016] The first step: take 525Kg of adipic acid and 575Kg of methanol, add 15Kg of concentrated sulfuric acid dropwise, reflux for 8 hours to evaporate the alcohol, wash with soda ash until the pH of the solution is neutral to obtain dimethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com