Variable-pressure adsorption oxygenerating device

A technology of pressure swing adsorption oxygen production and oxygen production equipment, which is applied in the direction of oxygen preparation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of oxygen production or oxygen consumption fluctuations, investment waste, system fluctuations, etc., and achieve Improve effective working time, reduce power consumption, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

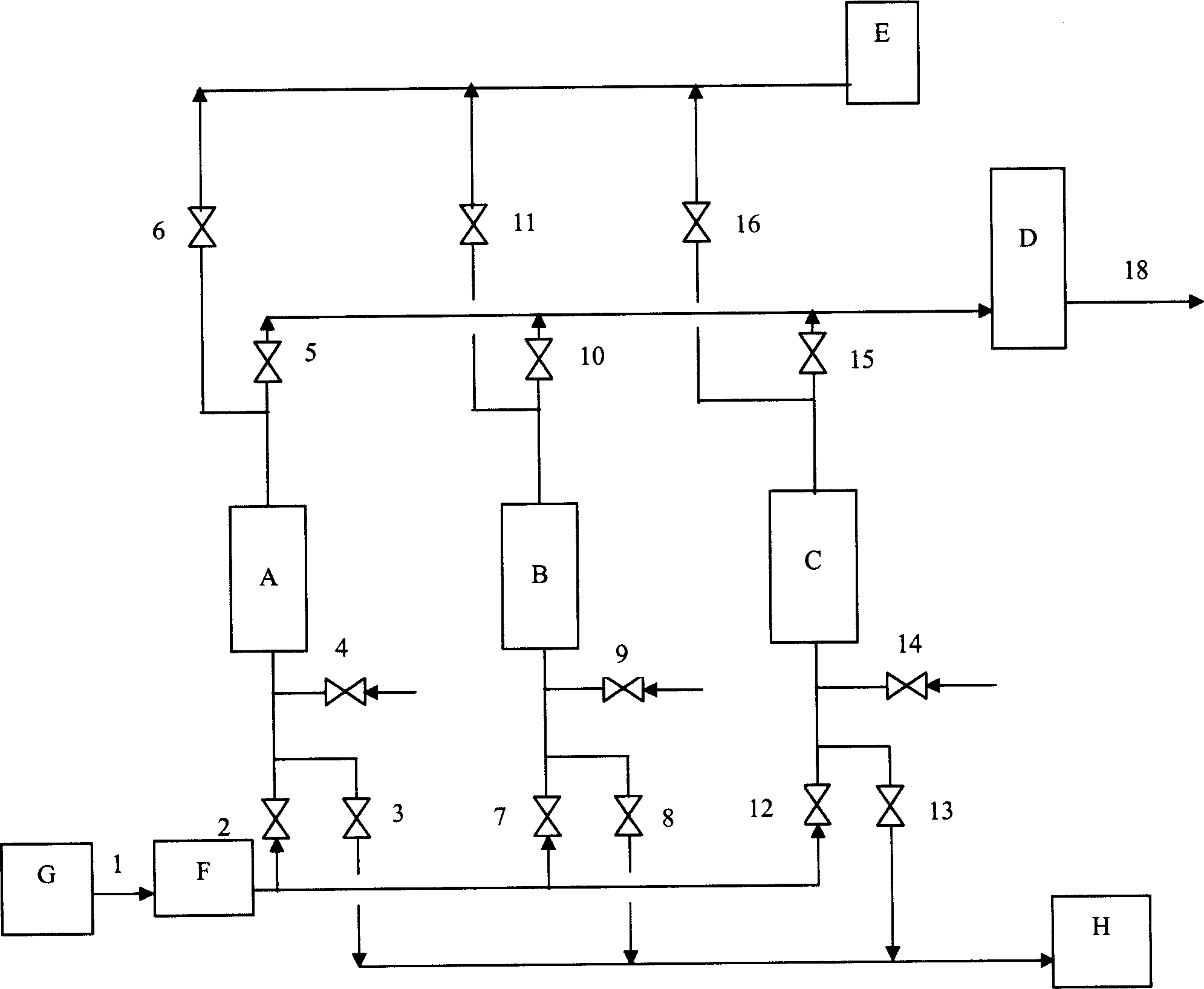

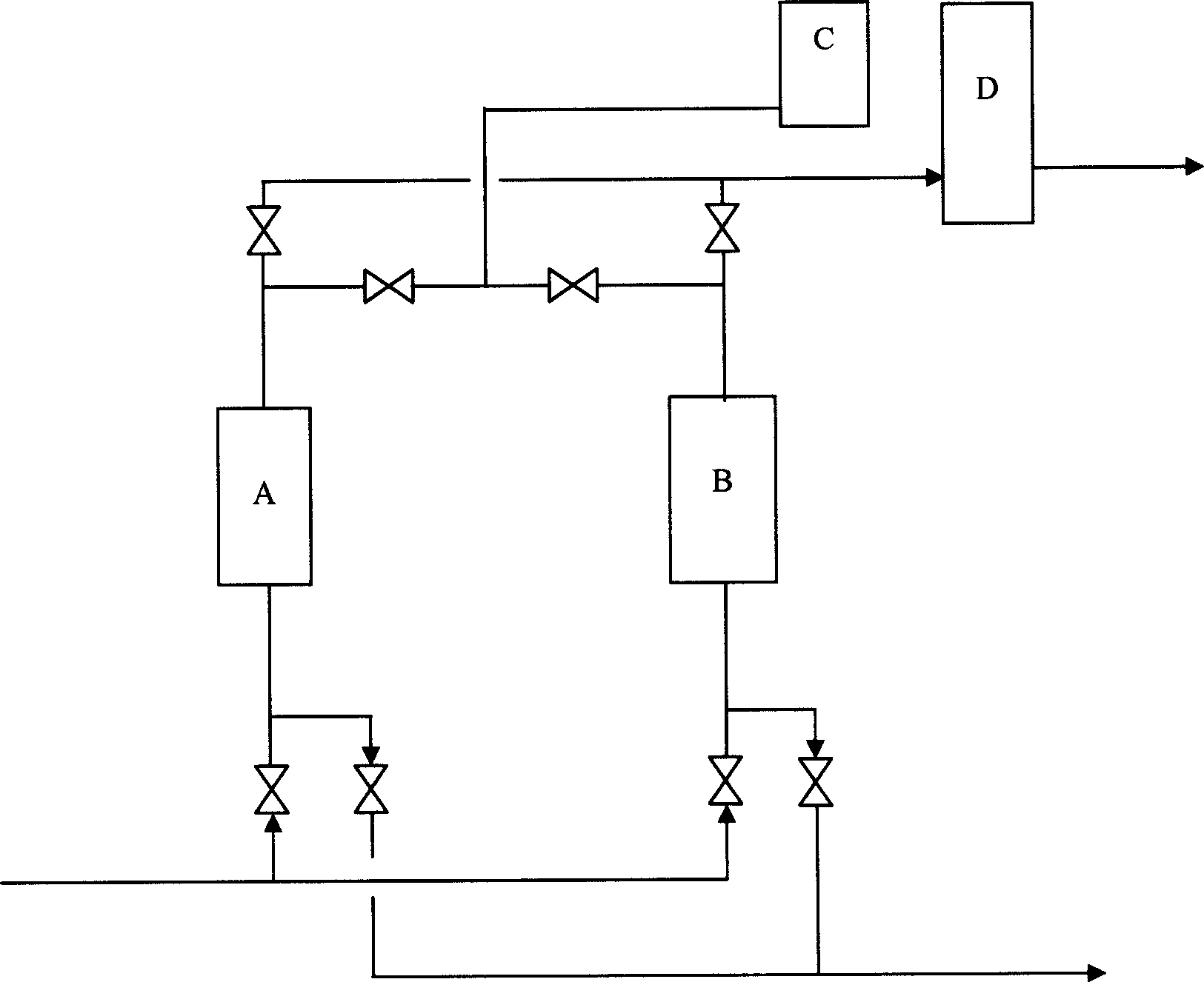

[0034]The flow structure principle of the pressure swing adsorption oxygen production device described in the present invention is shown in Figure 1, three oxygen production adsorption towers, one pressurized air floating gas cabinet, one oxygen product floating gas cabinet, and one transfer , Storage pressure equalization buffer tank, two vacuum pumps and two air blowers, one for maintenance and one for maintenance. The oxygen production cycle of each oxygen generation adsorption tower is 60 seconds, and the time allocation is 33.3% of vacuuming; the equalization is divided into two stages, and the first stage of equalization is 8%, from the pressure equalization buffer tank to the oxygen generation after vacuumization The air supply of the adsorption tower, the average increase is 8% in the second stage, the normal pressure air valve is opened, and the normal pressure air is provided to the oxygen production adsorption tower by the normal pressure air valve; the adsorption ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com