Heat-conductive characteristic detecting device and detecting method

A detection device and detection method technology, applied in the direction of measurement device, material thermal analysis, material thermal development, etc., can solve the problems of rapid screening of unfavorable thermal interface material samples, complex measurement steps, slow measurement speed, etc., and achieve fewer components. , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

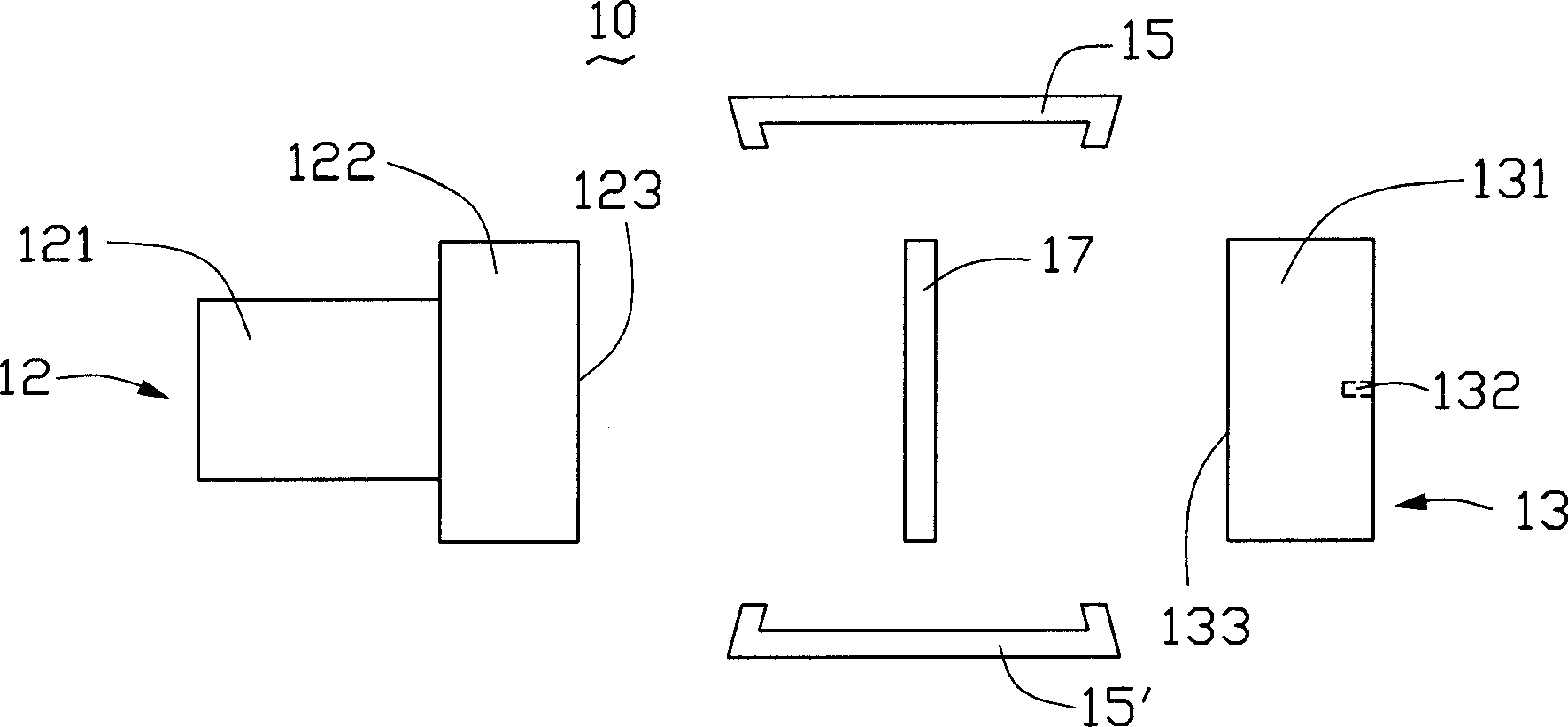

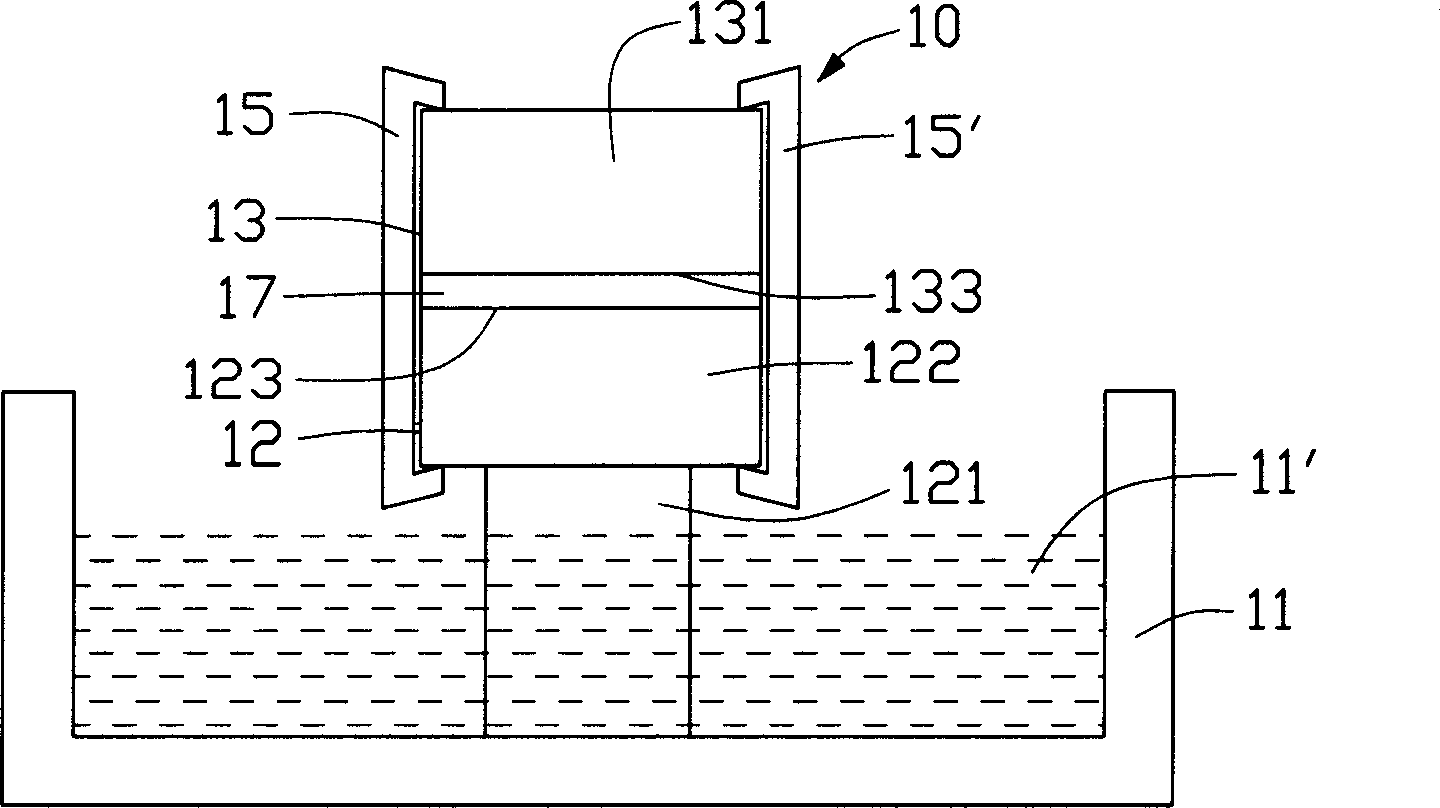

[0018] figure 1 It is an exploded schematic view of the thermal conductivity detection device of the first embodiment of the technical solution. The technical solution provides a thermal conductivity detection device 10, which includes a bearing part 12, a buckling part 13 and buckles 15, 15'. The carrying portion 12 includes a support block 121 with a first diameter and a first heat conduction block 122 with a second diameter integrally formed with the support block 121 . The support block 121 and the first heat conduction block 122 are a concentric cylinder, both of which are made of metal copper. The first diameter is smaller than the second diameter. The first heat conduction block 122 further includes a bearing plane 123 having a low surface roughness for bearing the thermal interface material 17 to be tested. The fastening part 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com