Personal matchbox and production thereof

A matchbox and outer box technology, applied in decorative arts, tobacco, packaging, etc., can solve the problems of lack of fashion, high startup cost, lack of interest, etc., to improve fashion and interest, simplify the manufacturing process, The effect of meeting individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

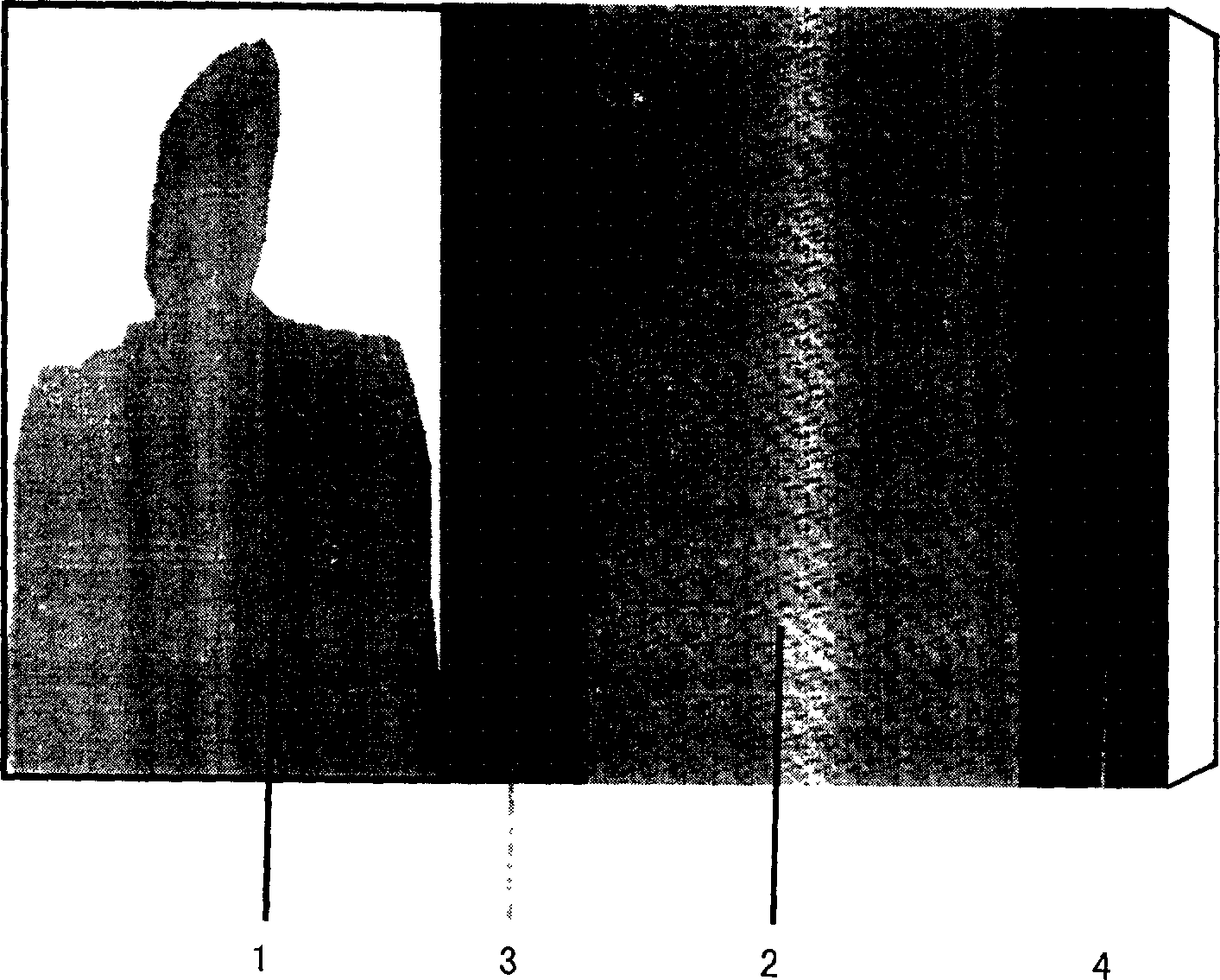

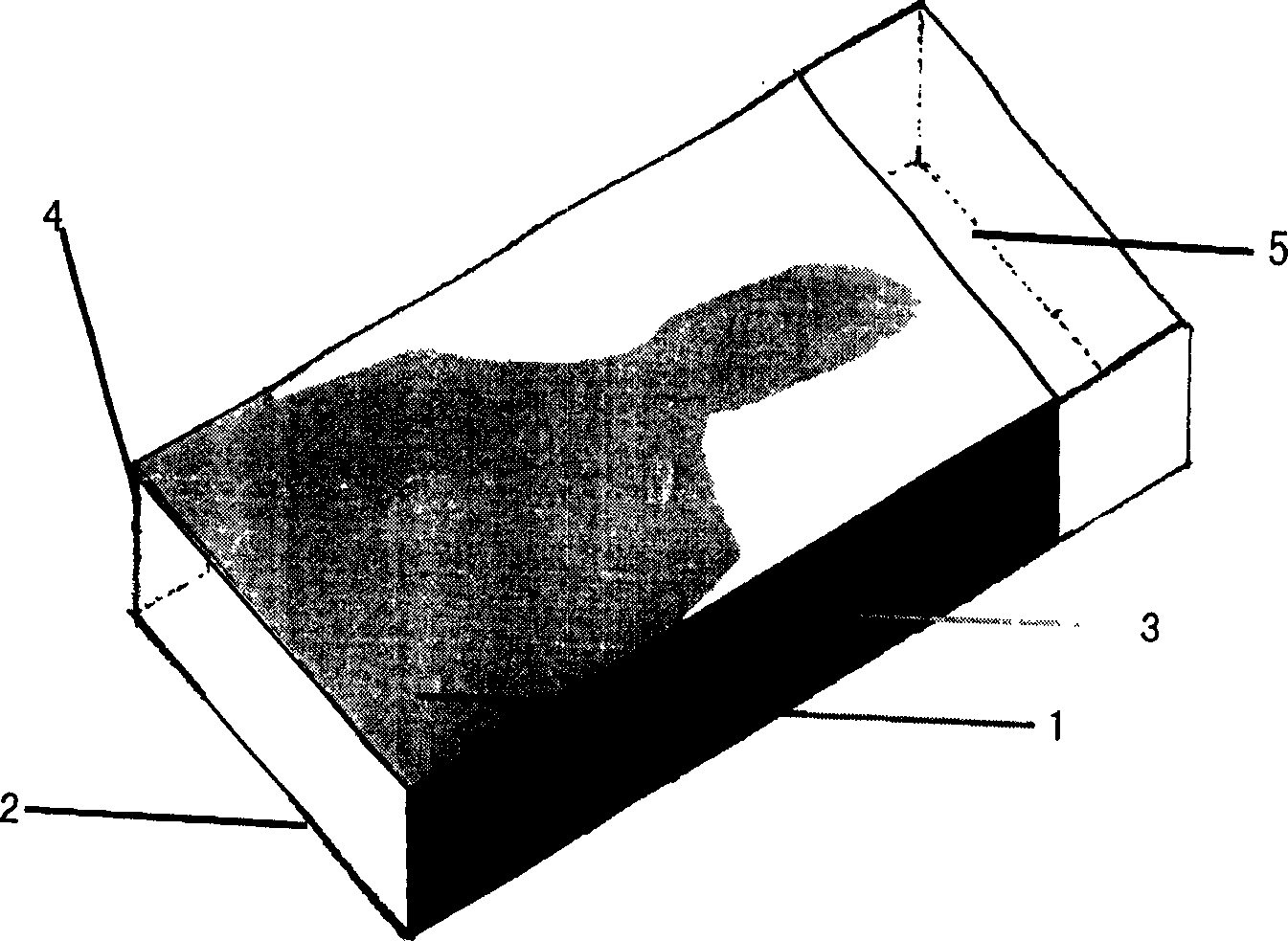

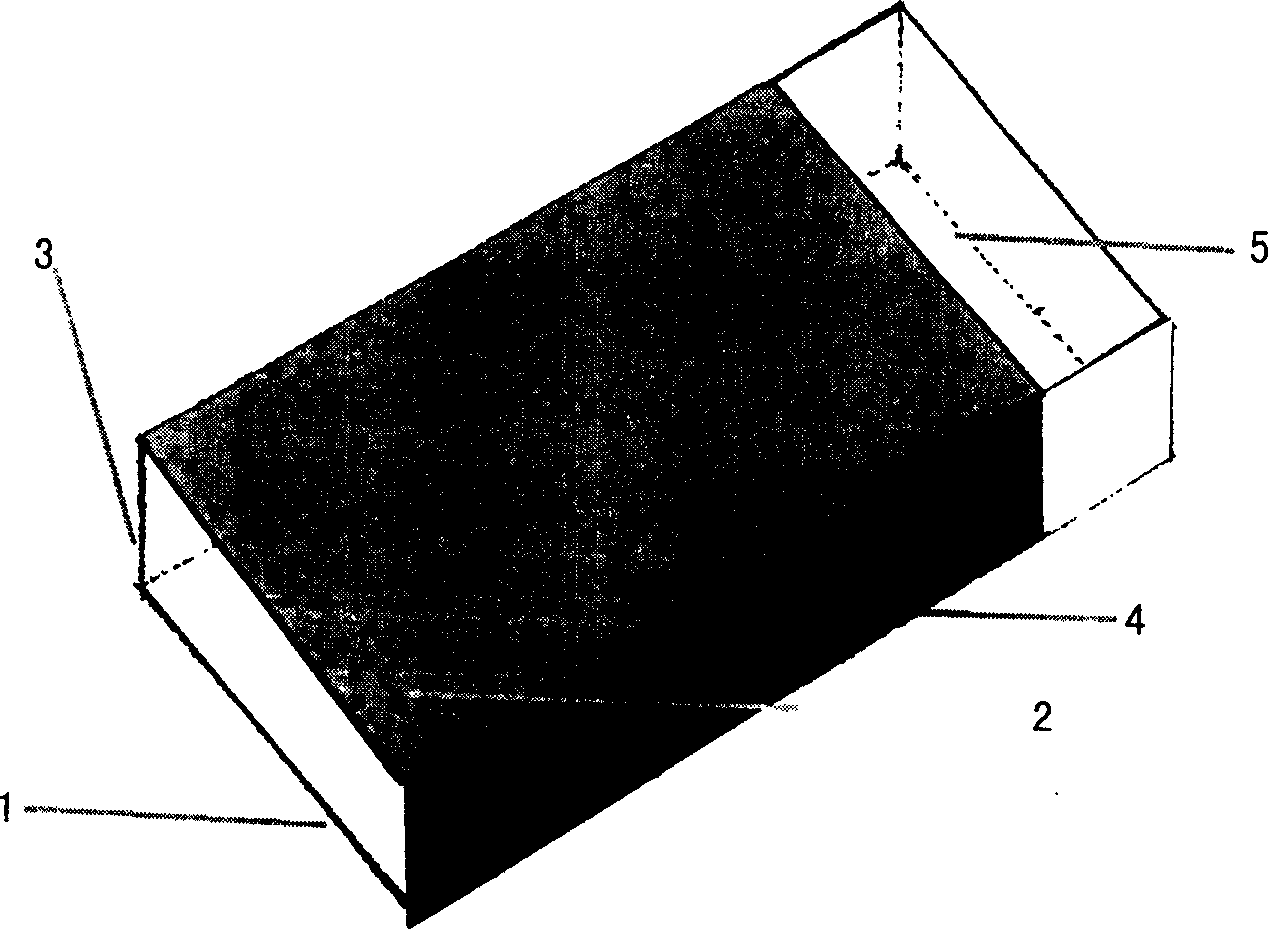

[0014] A. Process the photos, patterns and text submitted or selected by the user in the computer to create electronic files that can be printed. B. Print the electronic file with a laser printer on the cardboard for making personalized matchboxes, that is, on the pattern surface (1), pattern surface (2) and pattern surface (3) positions of the matchbox; the number of prints 100 copies; the printing resolution of the printing equipment is not less than 800×800dpi×8bit; the thickness of the selected cardboard is 240g / m 2 . C. Creasing stacked boxes, press and fold the cardboard with printed photos and texts with a creasing machine, fold it into a box shape according to the folding marks, and glue the folded cardboard into a box shape with double-sided tape or milky white adhesive material Glued into the outer box of a matchbox. D. Make inner box (5), make the inner box (5) of splendid attire matchstick by the specification size of outer box. G. brushing phosphorus slurry, br...

example 2

[0016] Preparation method is as example 1. Just use the digital printer to print artistic photos, famous quotes and pattern patterns respectively on the pattern surface (1), pattern surface (2) and pattern surface (3) positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com