Treatment and special treater of waste water in making salt and nitro-group

A waste water treatment, waste water technology, applied in the direction of water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of complex process technology, large equipment investment, high separation cost, etc., to achieve simple process, Less investment in equipment, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of nitrate making (salt making) wastewater treatment method described in the present embodiment comprises the following steps:

[0020] 1. Heating

[0021] The wastewater is heated to 60°C and maintained at this temperature.

[0022] 2. Add salt

[0023] Adding NaCl to the wastewater makes the Na in the wastewater 2 SO 4 Just right at the saturation point.

[0024] 3. Thickening

[0025] Thickening treatment is carried out for the waste water treated in step 2, so that the Na 2 SO 4 Crystallized out.

[0026] 4. Separation

[0027] For the wastewater treated in step 3, use a centrifuge or other existing processes to separate Na 2 SO 4 Crystals and NaCl slurry.

Embodiment 2

[0029] A kind of nitrate making (salt making) wastewater treatment method described in the present embodiment comprises the following steps:

[0030] 1. Heating

[0031] The wastewater is heated to 100°C and maintained at this temperature.

[0032] 2. Add salt

[0033] Adding NaCl to the wastewater makes the Na in the wastewater 2 SO 4 Just right at the saturation point.

[0034] 3. Thickening

[0035] Adopt thickener or other existing thickening equipment to carry out thickening treatment for the waste water processed through step 2, make the Na in the waste water 2 SO 4 Crystallized out.

[0036] 4. Separation

[0037] For the wastewater treated in step 3, use a centrifuge or other existing processes to separate Na 2 SO 4 Crystals and NaCl slurry.

Embodiment 3

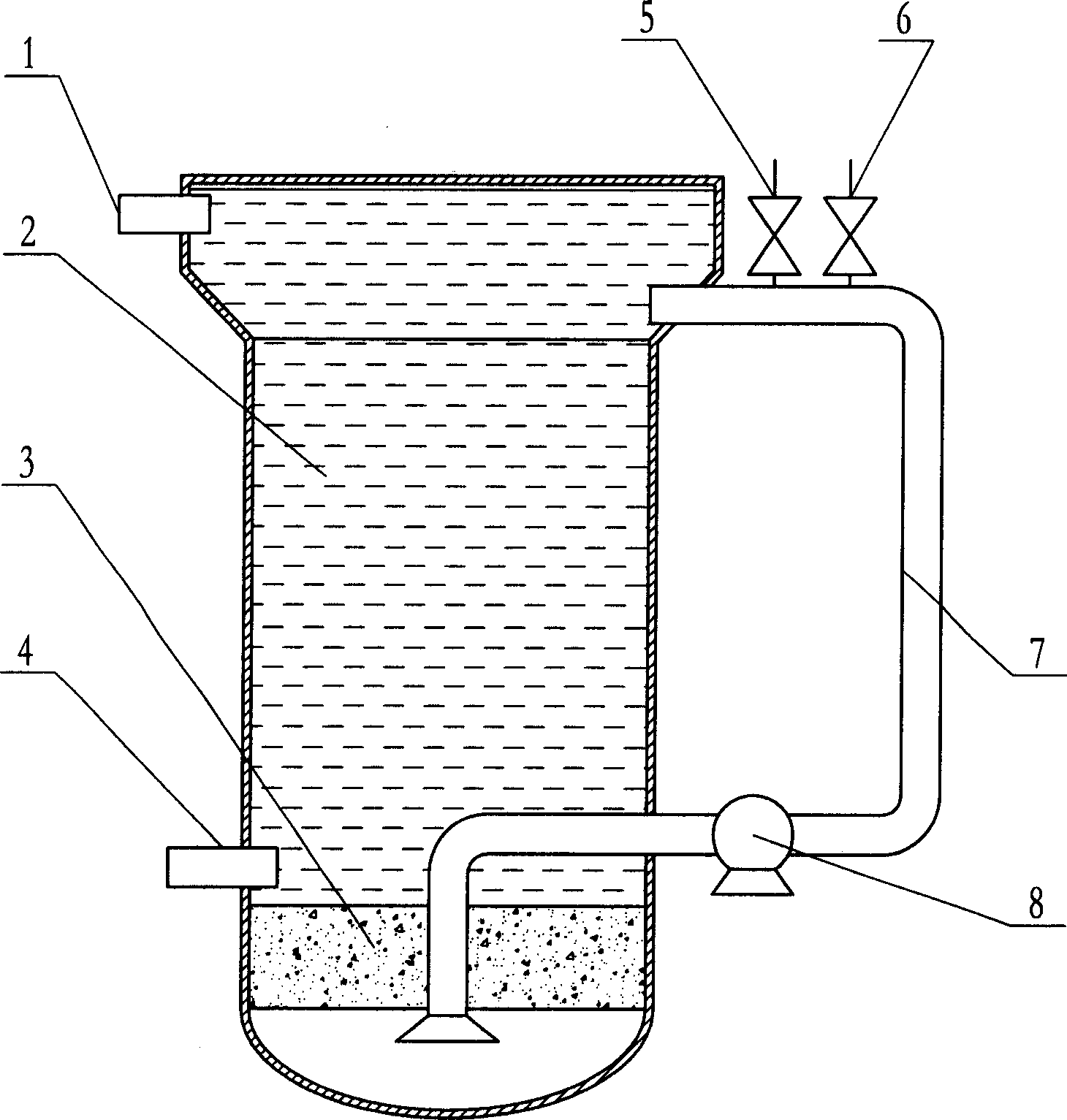

[0039] A special equipment for wastewater treatment of nitrate or salt production described in this embodiment includes a tank body 2, a circulation pipe 7, a circulation pump 8, a waste water inlet 5, a salt inlet 6, Na 2 SO 4 Slurry outlet 4, overflow port 1, suspended bed 3, etc., wherein the tank body 2 is a cylindrical container, the tank body 2 is provided with a heating device, the bottom of the tank body 2 is provided with a suspended bed 3, and one end of the circulation pipe 7 is located at The upper part of the tank body 2, the other end is arranged at the lower part of the tank body 2 and the suspension bed 3, and the circulating pump 8 is arranged in the circulating pipe 7 to transport the liquid in the upper part of the tank body 2 to the lower part of the tank body 2, and the circulating pipe 7 Also be provided with waste water inlet 5 and salt adding port 6, are respectively used for supplementing the waste water in the tank body 2 and adding salt to waste wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com