AC hot furnace device with plasma mine

A technology for plasma mines and submerged arc furnaces, which is applied in the field of smelting devices, can solve the problems of short service life of metal plasma guns, complicated equipment and large investment, and achieve the effects of saving electricity and increasing production, cheap equipment and less investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

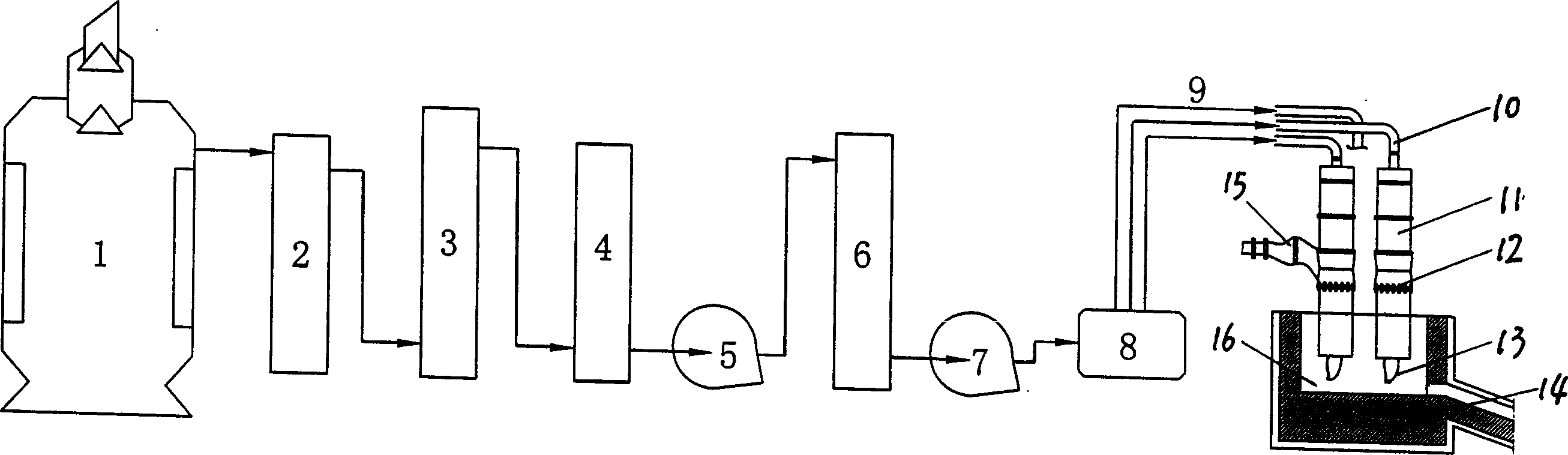

[0010] like figure 1 As shown, the AC plasma submerged arc furnace device is mainly composed of a submerged arc furnace and a carrier gas preparation device. The submerged arc furnace includes a self-baking electrode 11, a conductive copper tile 12, a short net 15, a hearth 16, and one end of the self-baking electrode 11. Located in the hearth 16, there are three self-baking electrodes 11, the self-baking electrodes 11 are connected with the short net 15 by the conductive copper tile 12, the short net 15 is connected with the AC power supply, and the AC power supply is a three-phase AC power supply. Each of the three self-baking electrodes 11 is buried with a seamless steel pipe. The lower end of the seamless steel pipe is located in the hearth. The diameter of the seamless steel pipe is φ8mm-φ20mm (the diameter is different depending on the capacity of the submerged arc furnace). The upper end is connected with one end of the air inlet pipe 10 by a flexible pipe; the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com