Manufacture method for semiconductor device having field oxide film

A device manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to obtain operational effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

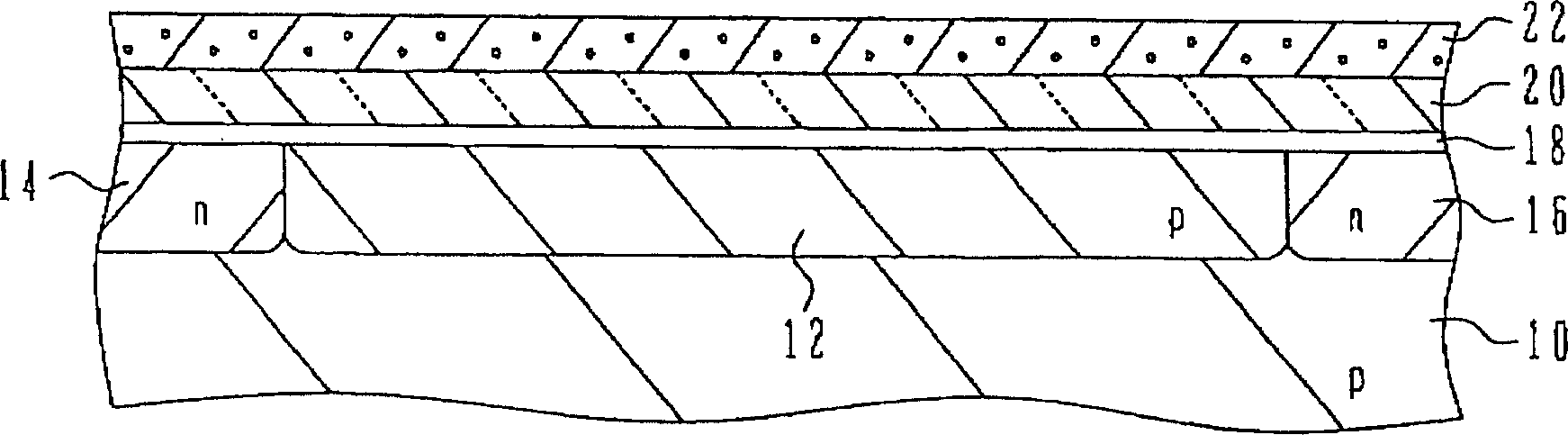

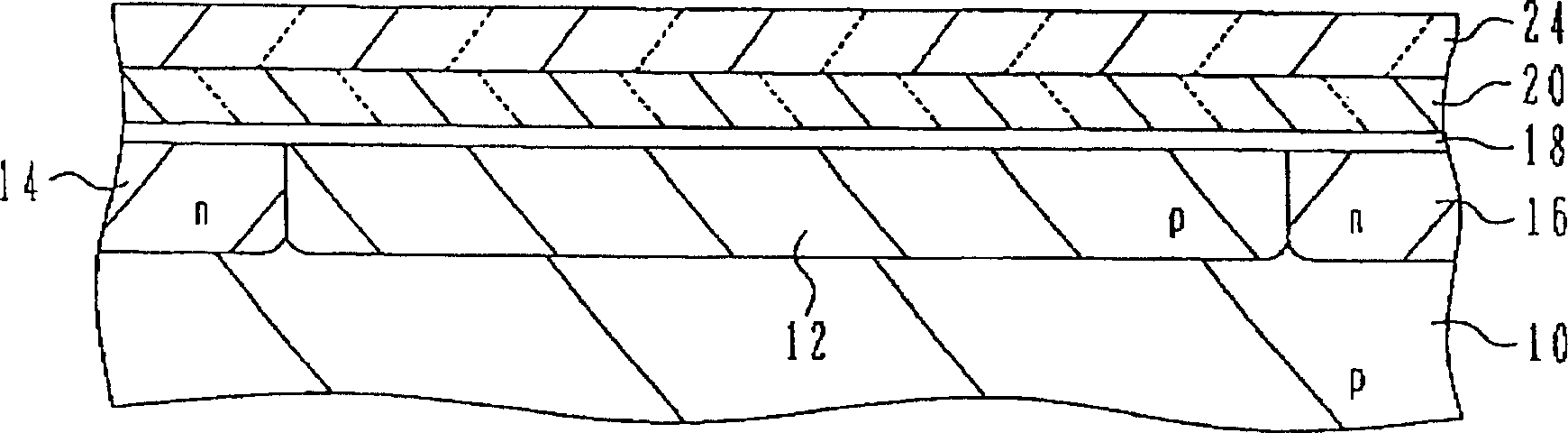

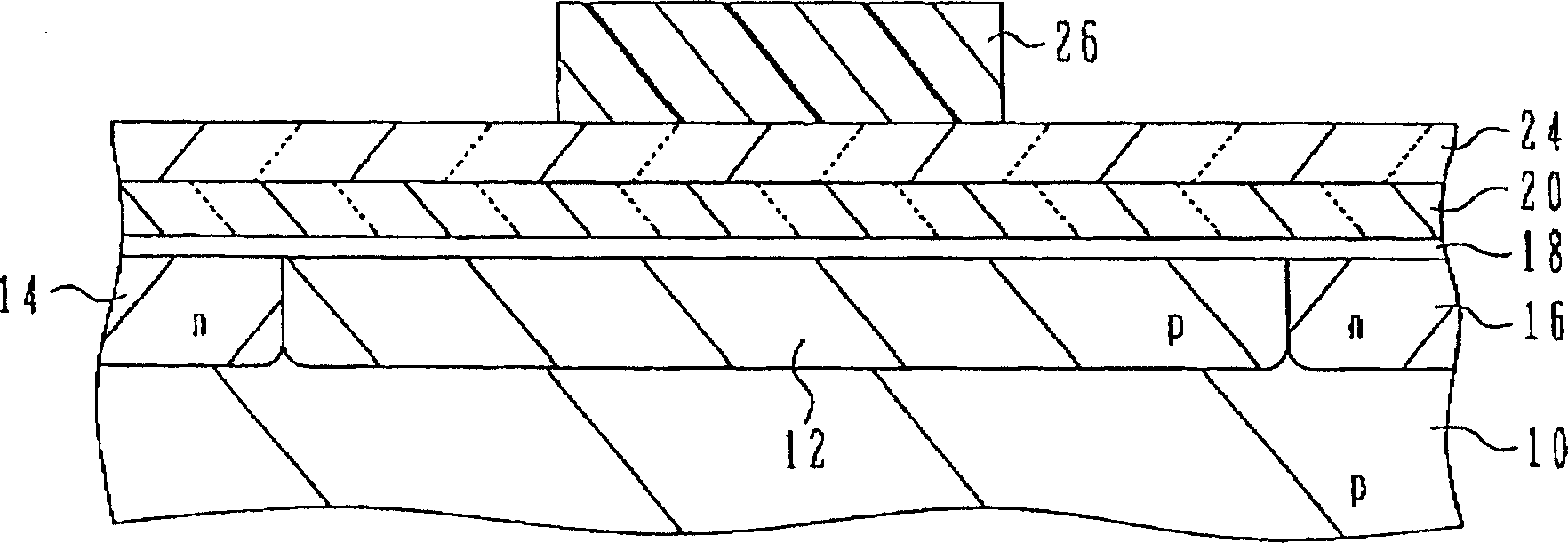

[0066] Figures 1A to 1J A method of manufacturing a metal oxide semiconductor (MOS) type integrated circuit (IC) using the field oxide film forming method according to the first embodiment of the present invention is shown. will be described in turn corresponding to Figures 1A to 1J craft.

[0067] exist Figure 1A In the process shown, p-type well region 12 and n-type well regions 14 and 16 are formed side by side on the main surface of p-type silicon substrate 10 by a known method. The n-type well regions 14 and 16 may be formed as one well region surrounding the p-type well region 12 . After well regions 12 to 16 are formed, silicon oxide film (stress relaxation pad oxide film) 18 is formed on the main surface of substrate 10 by thermal oxidation. The thickness of silicon oxide film 18 may be, for example, in the range from 30 nm to 40 nm. A silicon nitride film 20 is formed on the silicon oxide film 18 by CVD, and a polysilicon film 22 is formed on the silicon nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com