Method for preventing metals from being damaged by high density plasma chemical vapor deposition

A chemical vapor deposition, chemical vapor deposition technology, applied in the direction of gaseous chemical plating, metal material coating process, electrical components, etc., can solve problems such as metal damage, to reduce damage, good protection, good sidewall coverage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

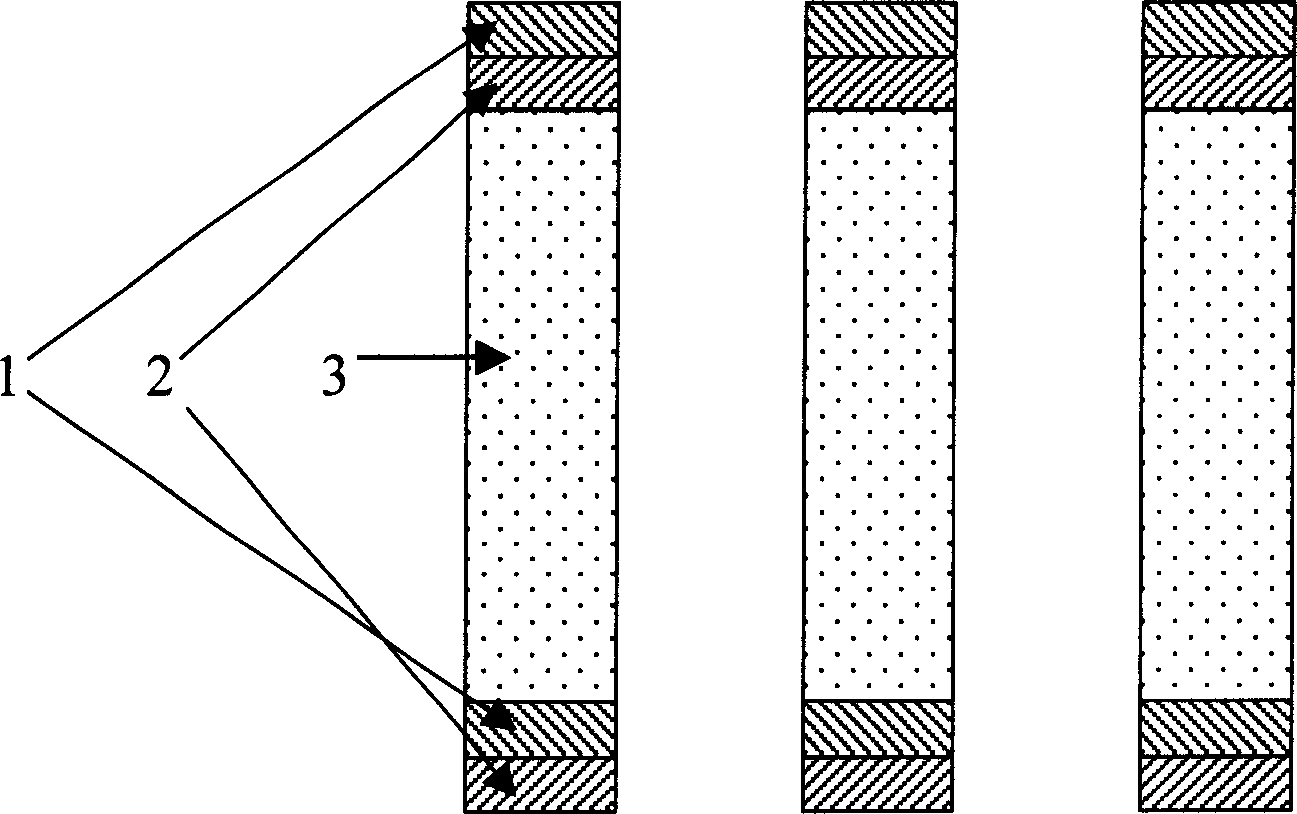

[0021] see figure 1 In the integrated circuit manufacturing process, metal etching needs to be completed. In this embodiment, the metal layer includes titanium nitride 1 , titanium 2 and aluminum-copper alloy / aluminum 3 .

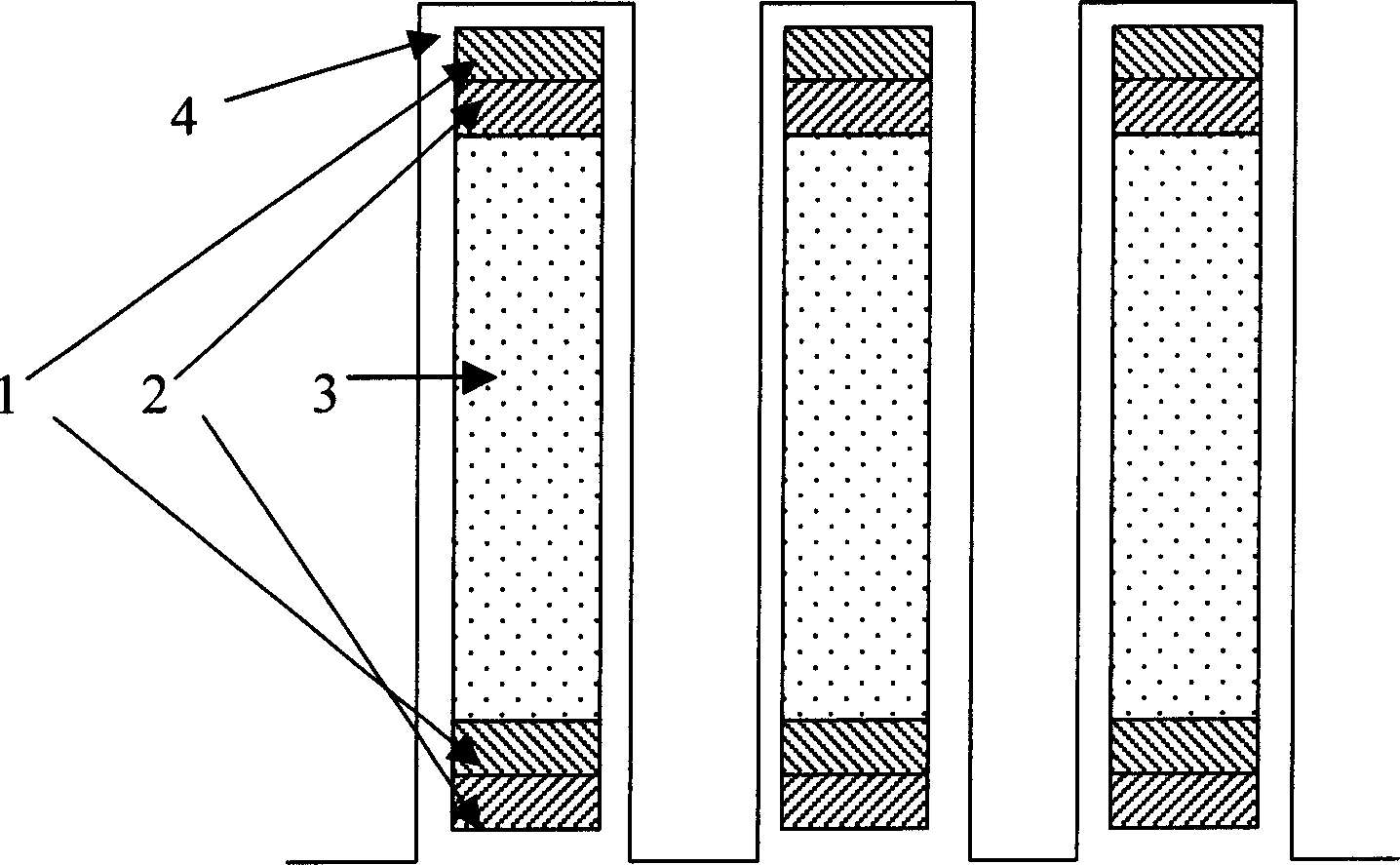

[0022] see figure 2 After the metal is etched, a layer of silicon dioxide is deposited on the etched surface by plasma-assisted chemical vapor deposition (PECVD). figure 1 The middle metal layer is used as the substrate for deposition. In this embodiment, plasma-assisted chemical vapor deposition (PECVD) is performed on the silicon wafer that has been etched by metal, such as deposited in the chamber of the Producer CVD of Applied Materials, and the formed silicon dioxide (SiO 2 ) layer thickness of 200A, 300A or 500A.

[0023] Among them, the precursor in plasma-assisted chemical vapor deposition (PECVD) is tetraethylorthosilicate (TEOS), and the reaction gas is oxygen (O 2 ), the temperature in the plasma-assisted chemical vapor deposition is 350° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com