Fixed yeast bio- alcohol fermentation system

A technology for immobilizing yeast and bio-alcohol, applied in the system field of the field of bioengineering technology, can solve the problems of not fully utilizing the cell density of immobilized yeast particles, not reaching the fermentation speed of immobilized particles alcohol fermentation, and not recycling carbon dioxide. , to achieve the effect of less floor space, high utilization rate and fast fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

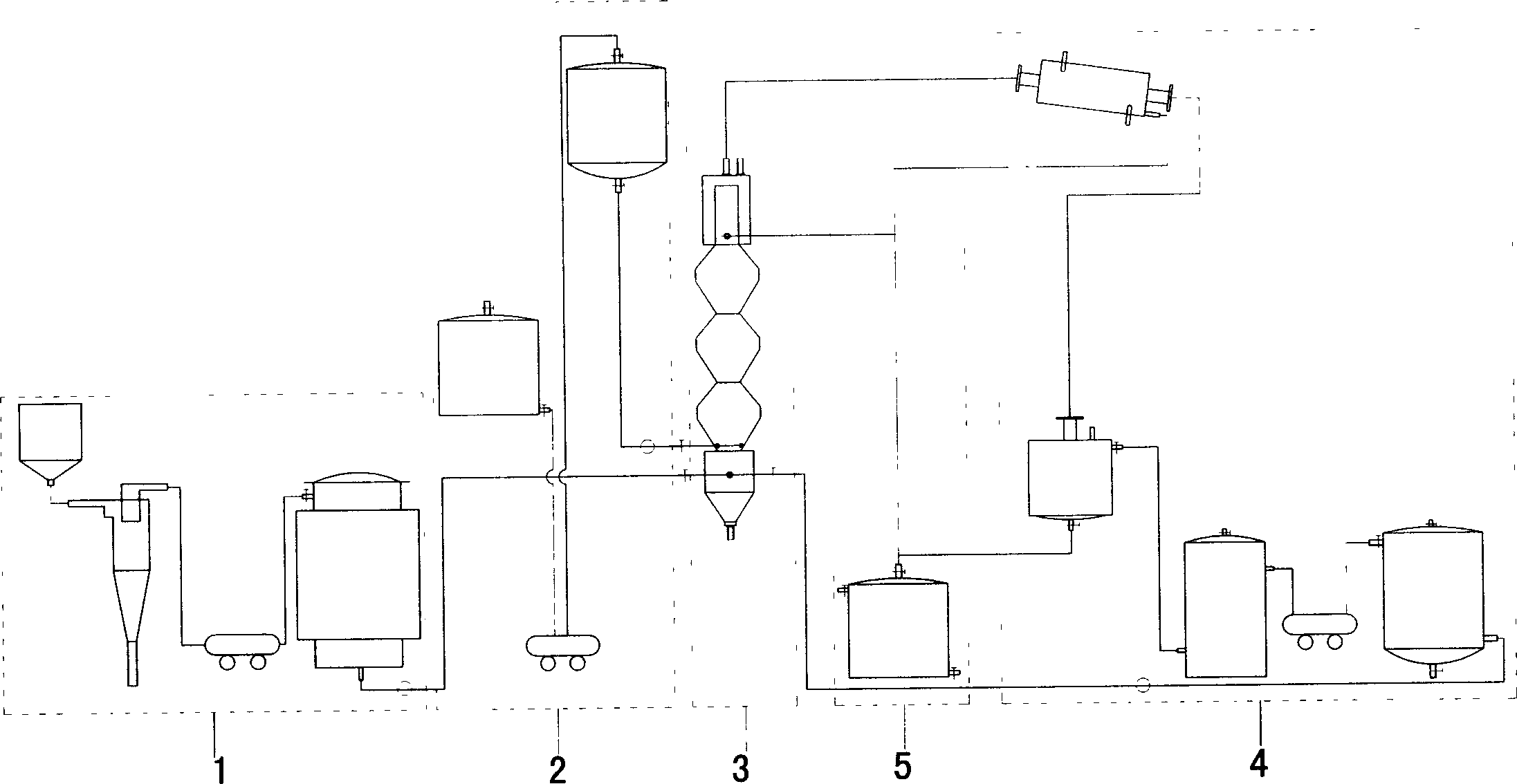

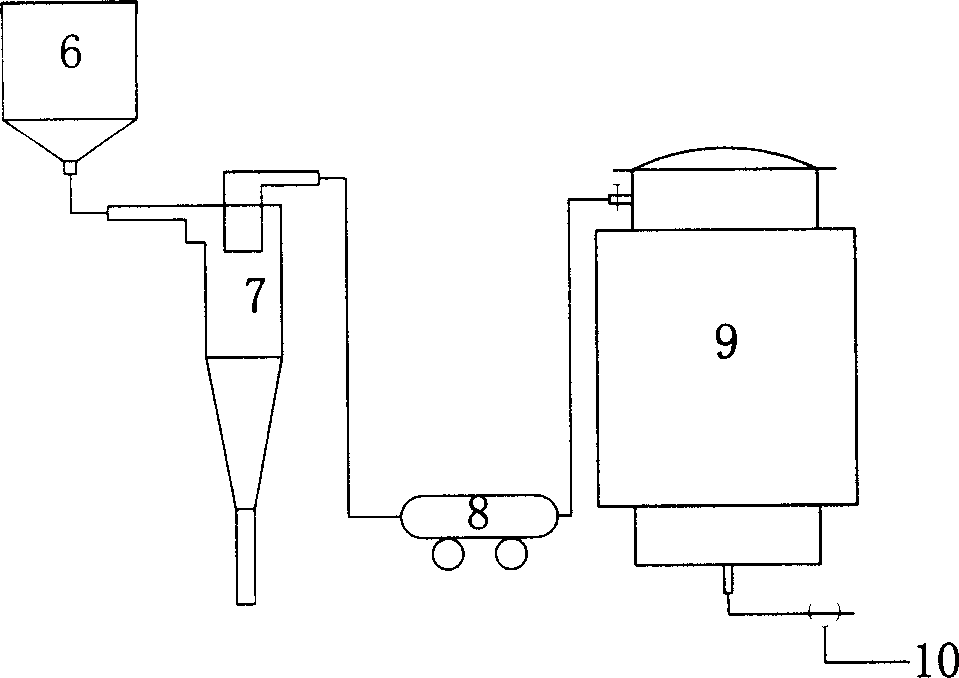

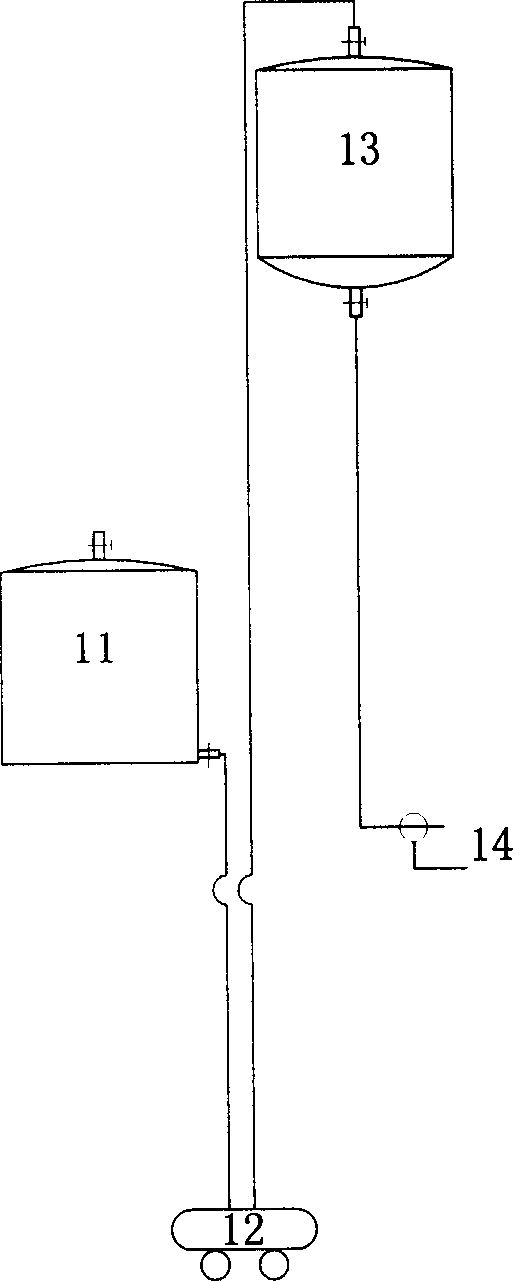

[0023] Such as figure 1As shown, the present invention includes: an air purification system 1, a fermentation liquid feeding system 2, an immobilized yeast fluidized bed fermentation reactor system 3, a carbon dioxide circulation system 4 and a fermentation mash collection system 5. The air purification system 1 is connected to the lower part of the immobilized yeast fluidized bed reactor system 3 with a rubber tube or a metal tube, and the sterile air obtained through the air purification system 1 is blown in from the bottom of the immobilized yeast fluidized bed fermentation reactor system 3 , to provide fluidization power for the multiplication process of immobilized yeast before fermentation, and at the same time provide an aerobic environment for the multiplication of yeast; the fermentation liquid feeding system 2 is connected to the immobilized yeast fluidized bed reactor system 3 through rubber tubes or metal tubes In the middle part, the prepared aseptic fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com