Electrochemical device

An electrochemical and electrode technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of short circuit between electrodes, deterioration of uniformity, large leakage current between electrodes, etc., and achieve the effect of less leakage current and higher uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

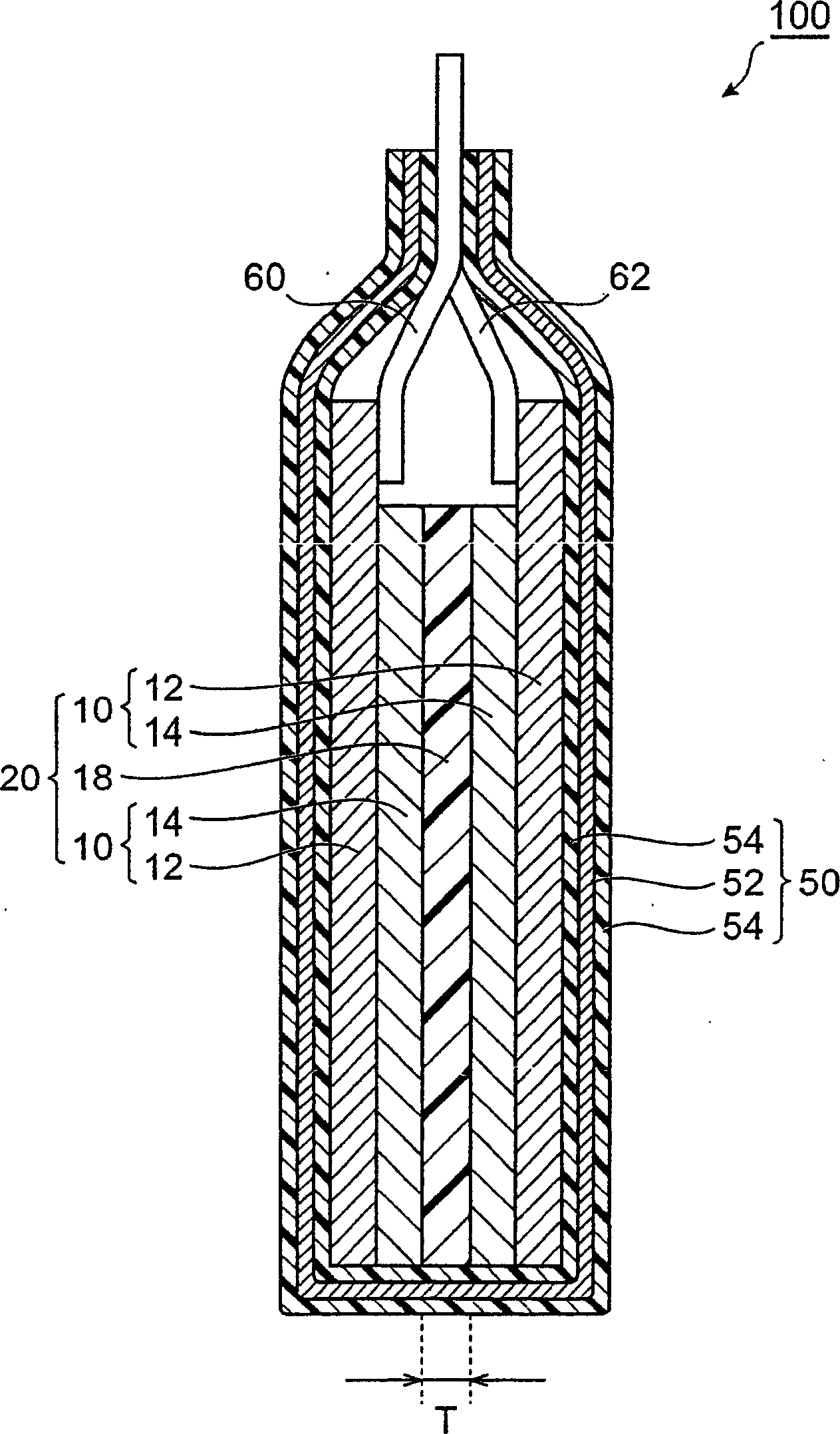

Image

Examples

Embodiment 1

[0045] The electric double layer capacitor of Example 1 was fabricated in the following manner.

[0046]

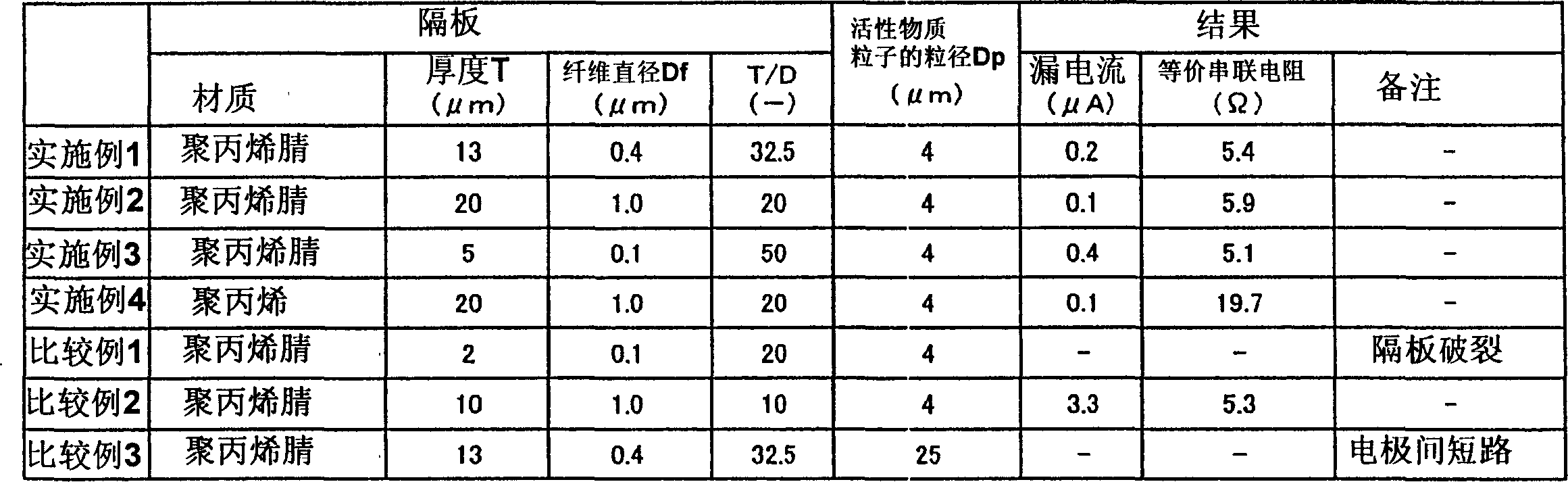

[0047] Activated carbon is used as an active material, carbon black is used as a conductive additive, and PVDF is used as a binder, and these materials are mixed so that the active material: conductive additive: binder = 87:3:10, and N is added to the resulting mixture. -Methylpyrrolidone, kneading, thereby preparing a paint. The average particle diameter Dp of the activated carbon was 4 μm.

[0048] After coating this paint on one surface of the etched aluminum foil by a doctor blade method, the aluminum foil was dried at 100° C. for 30 minutes in the air. The aluminum foil was calendered using a roll press, and then, centered on the coating film formation area, the aluminum foil was punched out with a hole of 7.8×7.8 mm having a tab portion to obtain an electrode for an electric double layer capacitor.

[0049]

[0050] A nonwoven fabric made of polyacrylonitrile wi...

Embodiment 2

[0054] In Example 2, an electric double layer capacitor was obtained in the same manner as in Example 1, except that a nonwoven fabric made of polyacrylonitrile having a thickness T of 20 μm and a fiber diameter D of 1 μm was used as the separator.

Embodiment 3

[0056] In Example 3, an electric double layer capacitor was obtained in the same manner as in Example 1, except that a nonwoven fabric made of polyacrylonitrile having a thickness T of 5 μm and a fiber diameter D of 0.1 μm was used as the separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com