Crude zinc smelting method and smelting furnace therefor

A smelting method and smelting furnace technology, which are applied in the field of smelting furnaces, can solve the problems of low utilization rate of heat energy, high production cost and large investment, and achieve the effects of improving utilization rate of heat energy, reducing production cost and high utilization rate of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

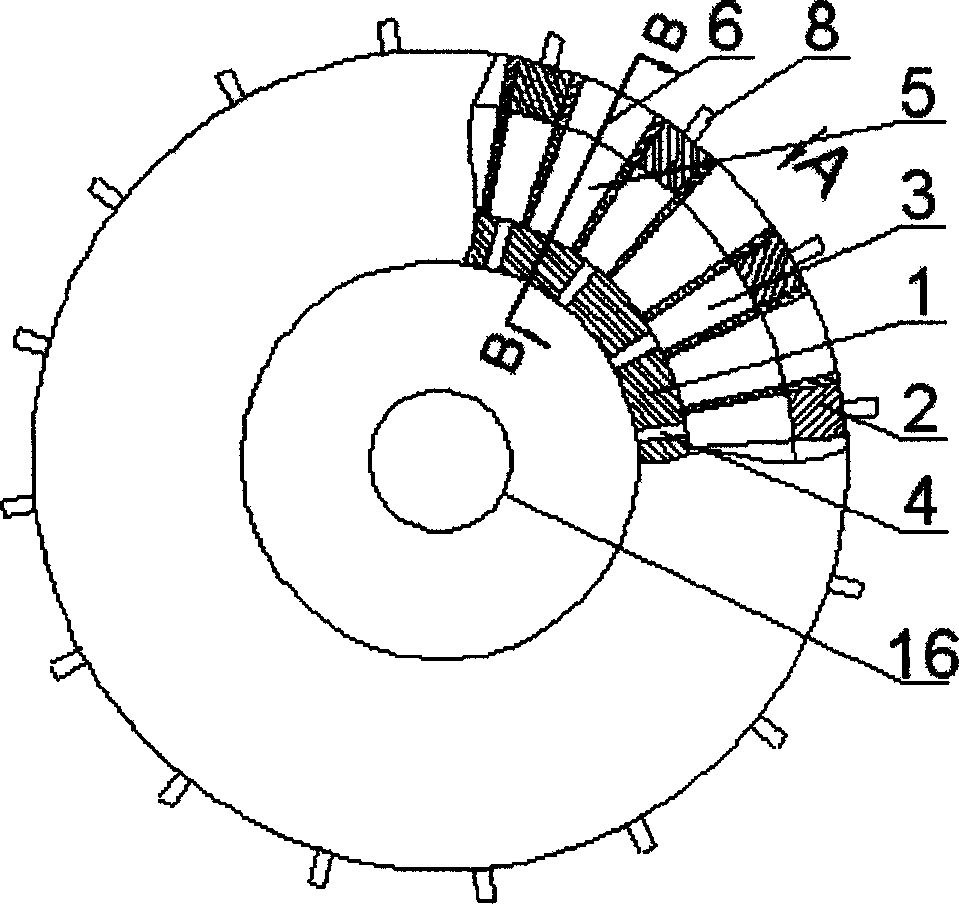

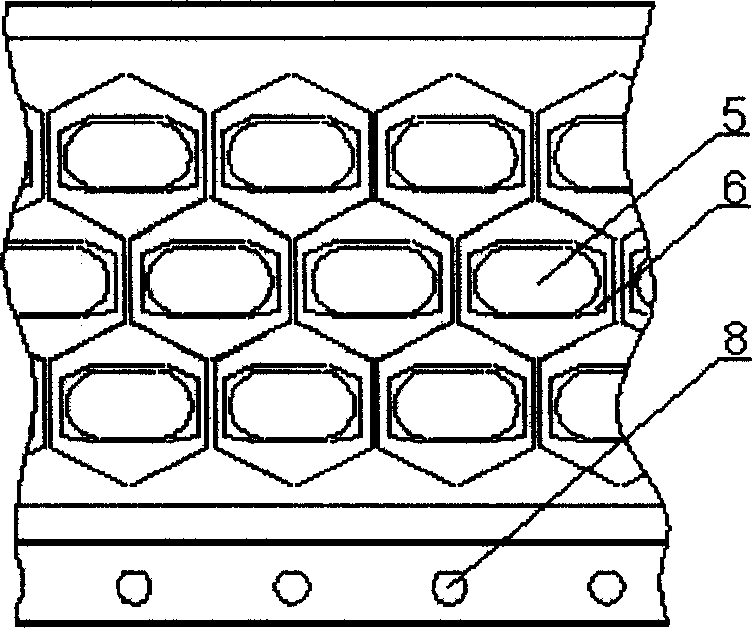

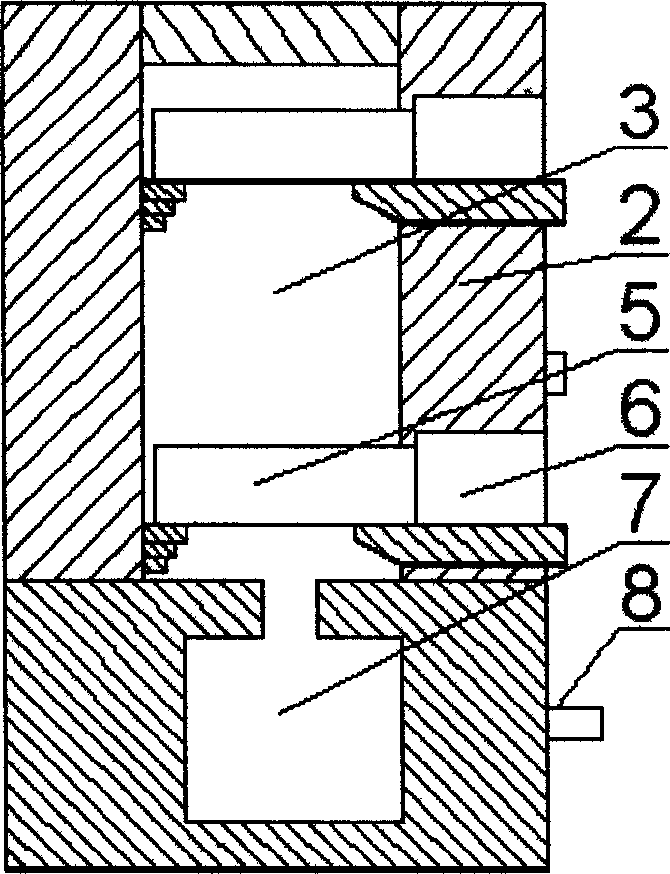

[0021] Embodiments of the invention. Crude zinc smelting method and its smelting furnace, first use refractory bricks to build a ring-shaped inner wall 1 and outer wall 2, the middle of the inner wall 1 and the outer wall 2 is a combustion chamber 3, and install a circle of gas and hot air nozzles on the inner wall 1 4. The gas and hot air nozzle 4 is connected to the gas generator 16. The gas generator can be installed in the middle of the inner wall 1, and a circle of smelting tanks 5 is installed in the combustion chamber 3. In order to facilitate installation, the smelting tanks 5 are one large and one small at both ends. The elliptical table shape, the small end of the radius is sealed, installed on the inner wall 1, the large end of the radius is connected to the condenser 6, and the smelting tank 5 is made of silicon carbide material, which can be recycled after damage. The smelting tank 5 is vertically distributed in three layers in the combustion chamber 3, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com