Method for preparing porous polymer piezo-electric electret thin film

A technology of porous polymers and piezoelectric electrets, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of not being able to form ideal porous Structure, limit the application of functional materials, piezoelectric activity reduction and other issues, to achieve the effect of novel concept, high thermal stability, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

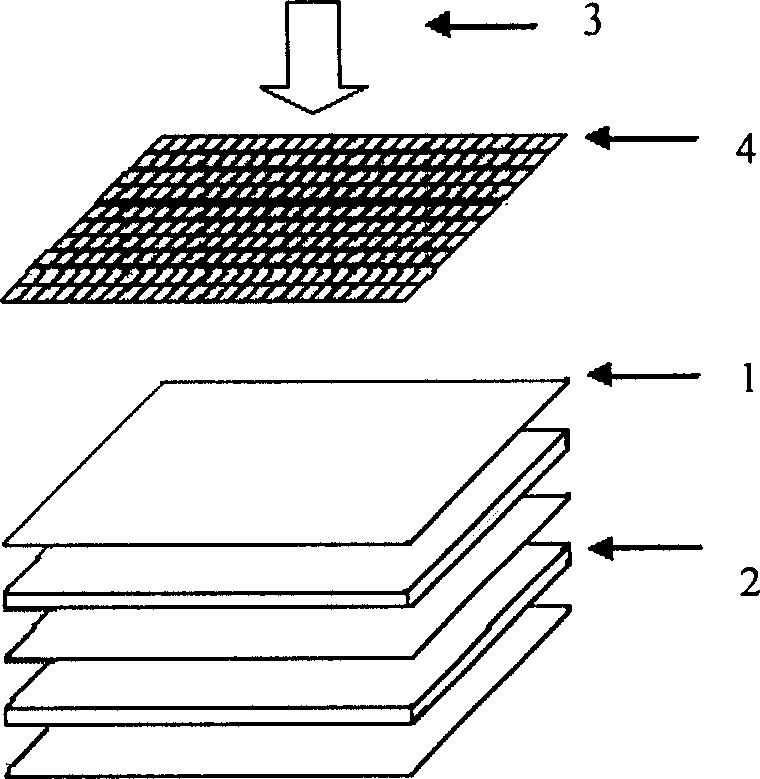

[0031] Embodiment 1, a metal grid is used, and the mesh is a 1mm×1mm square hole. Film 1 is made of FEP film (two layers) with a film thickness of 12.7 μm; film 2 is made of PTFE film (three layers) with a film thickness of 3 μm. The pressing temperature is 280°C; the pressing time is 15 minutes; and the pressing pressure is 4kPa. The corona electrode is needle-shaped; the corona voltage is 32kV; there is no grid control voltage; the charging temperature is 20°C; the charging time is 60s; the distance between the corona electrode and the sample is 7cm. Aluminum electrodes of 100 nm were vacuum-deposited on both sides of the porous membrane.

Embodiment 2

[0032] In embodiment 2, a metal grid is used, and the mesh is a square hole of 0.125mm×0.125mm. Film 1 is made of FEP film (one layer) with a film thickness of 12.7 μm; film 2 is made of PTFE film (two layers) with a film thickness of 3 μm. The pressing temperature is 280°C; the pressing time is 5 minutes; and the pressing pressure is 4kPa. The corona electrode is needle-shaped; the corona voltage is 64kV; there is no grid control voltage; the charging temperature is 25°C; the charging time is 40s; the distance between the corona electrode and the sample is 4cm. Aluminum electrodes of 100 nm were vacuum-evaporated on both sides of the porous membrane.

Embodiment 3

[0033] Embodiment 3, a metal grid is used, and the mesh is a square hole of 0.125mm×0.125mm. Film 1 is made of FEP film (one layer) with a film thickness of 12.7 μm; film 2 is made of PTFE film (two layers) with a film thickness of 3 μm. The pressing temperature is 280°C; the pressing time is 10 minutes; and the pressing pressure is 4kPa. The corona electrode is needle-shaped; the corona voltage is 5kV; there is no grid control voltage; the charging temperature is 20°C; the charging time is 10 minutes; the distance between the corona electrode and the sample is 10cm. Aluminum electrodes of 100 nm were vacuum-deposited on both sides of the porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com