Large continuous planetary ball mill

A planetary ball mill, feeding and discharging technology, applied in the direction of grain processing, etc., can solve the problems of low work efficiency, high wear of hard alloy steel, etc., to achieve the effect of reduced wear, good grinding efficiency and energy saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

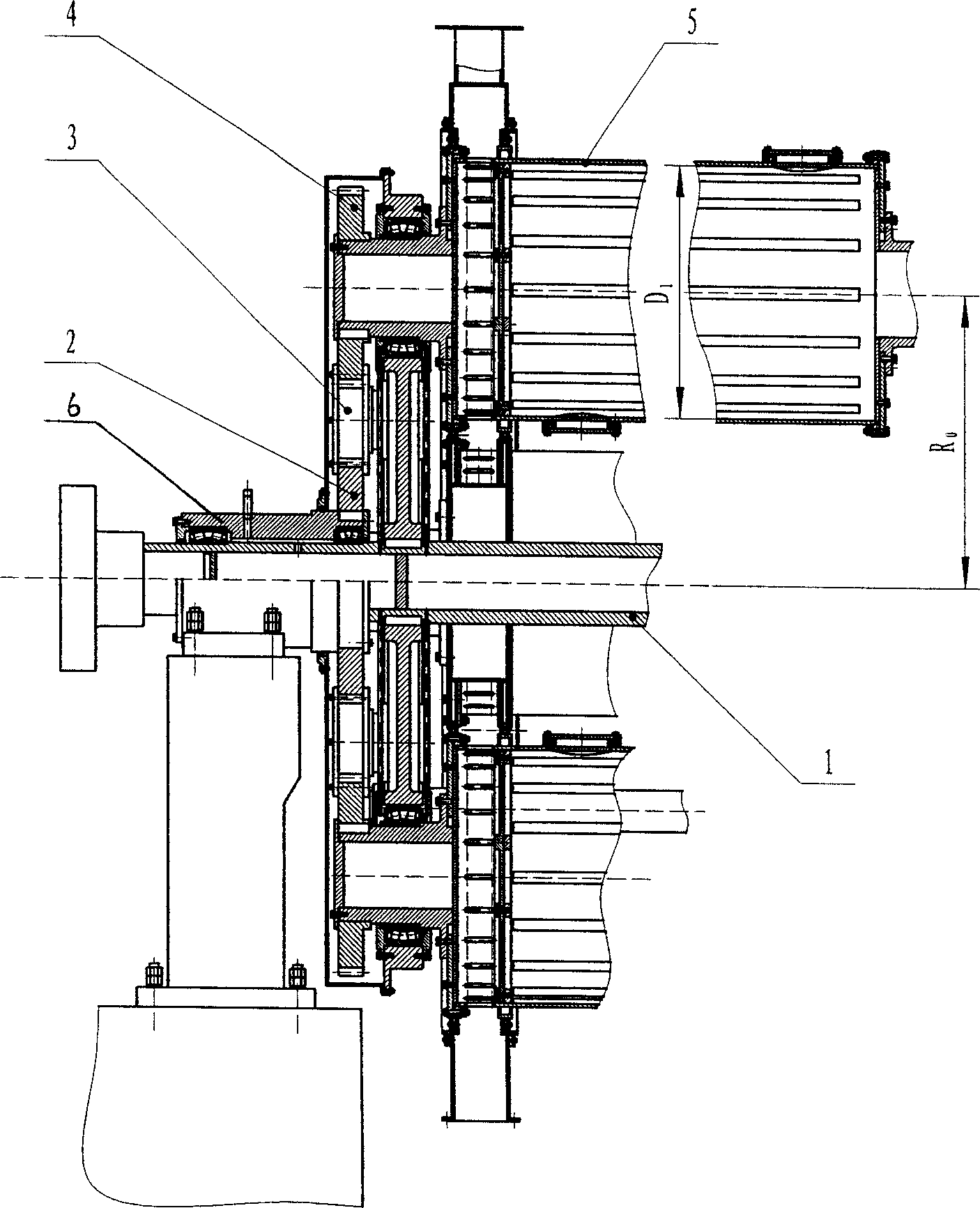

[0008] Such as figure 1 As shown, the present invention includes a main shaft 1 , a central gear 2 , an idler gear 3 , a grinding cylinder gear 4 and a grinding cylinder 5 . The central gear 2 is fixed on the bearing seat 6 of the main shaft 1 and arranged concentrically with the main shaft 1 , and the grinding cylinder gear 4 is concentrically connected to the end of the grinding cylinder 5 . The idler gear 3 meshes with the central gear 2 and the grinding barrel gear 4 respectively.

[0009] The central axis of the grinding cylinder 5 is parallel to the axis of the main shaft 1, and the distance between the two axes is R 0 , the effective inner diameter of the grinding cylinder D 1 with R 0 The ratio D 1 :R 0 =1:0.8~1.2. Gear teeth number z of grinding cylinder 5 1 and the number of teeth z of the sun gear 2 2 The ratio z 1 : z 2 =1:0.8~1.2.

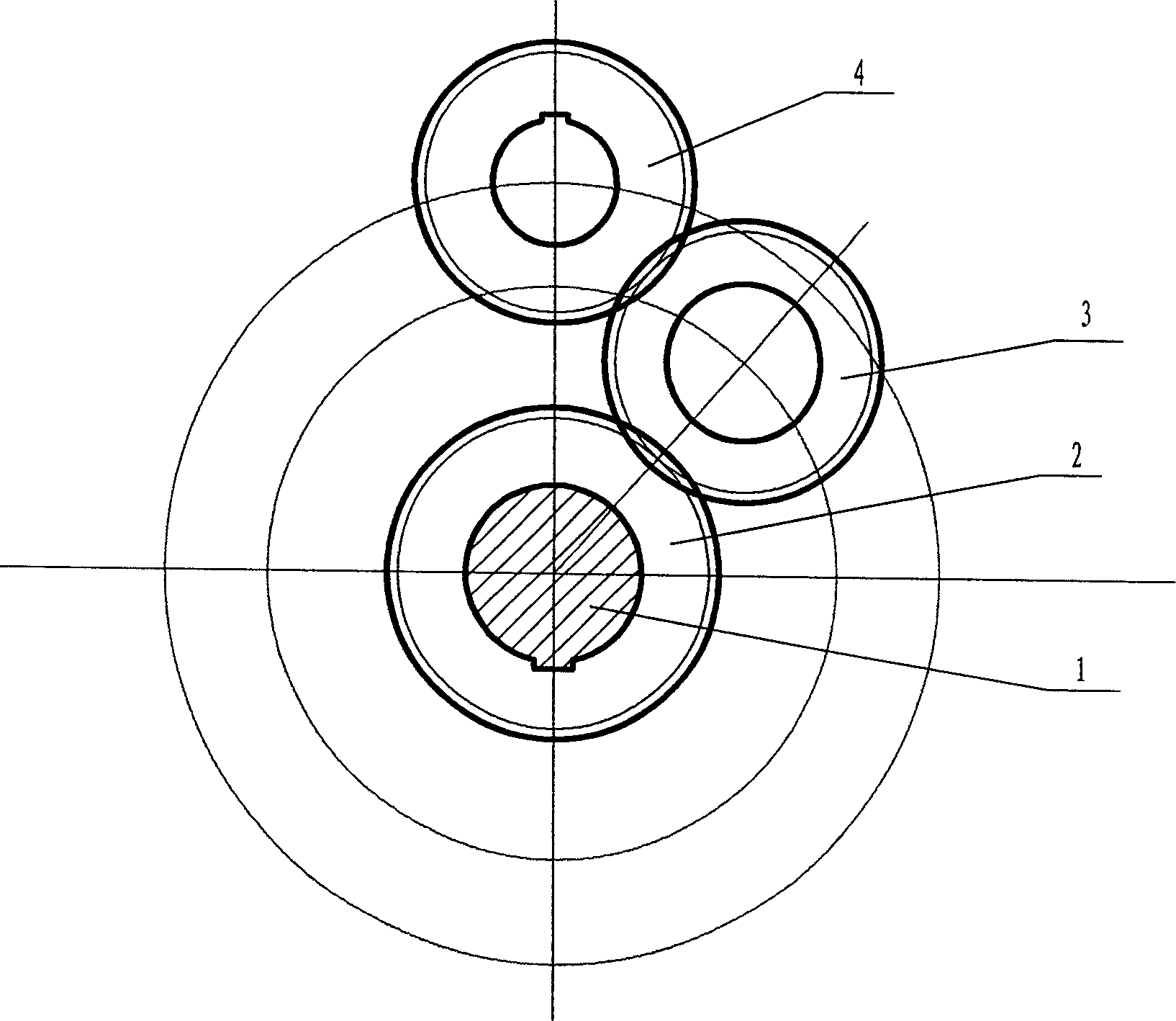

[0010] Such as figure 2 Shown is the positional relationship and meshing relationship among the central gear 2, the idle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com