Method and device for preparing methyl formate by methanol carbonylation

A technology of methanol carbonylation and methyl formate, which is applied in the direction of carbon monoxide or formate reaction preparation, organic chemistry, etc., can solve the problems of system and environmental pollution, high catalyst consumption, high production energy consumption, etc., to reduce consumption and save investment , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention adopts a reactive distillation process to prepare methyl formate through a methanol carbonylation method.

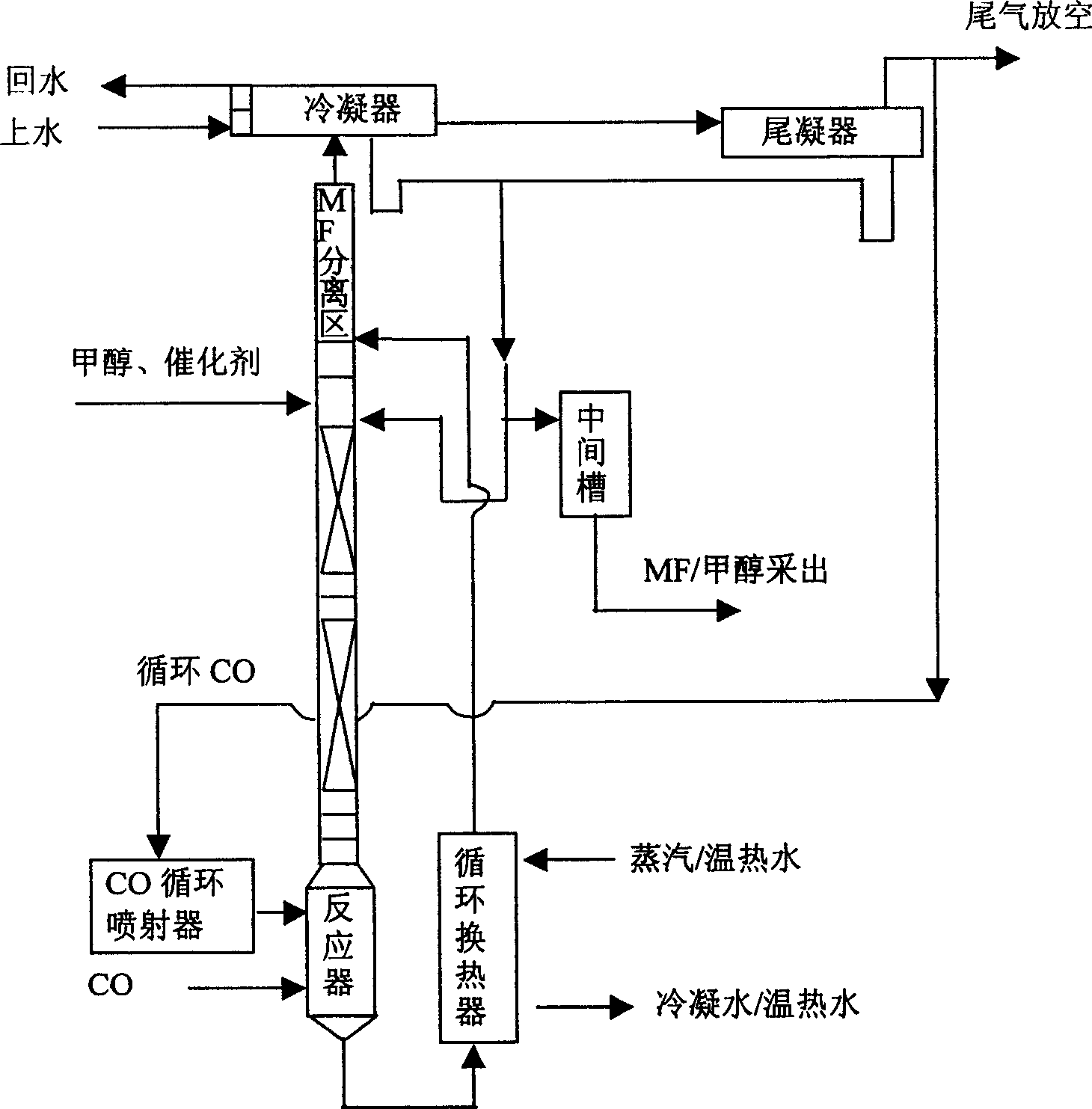

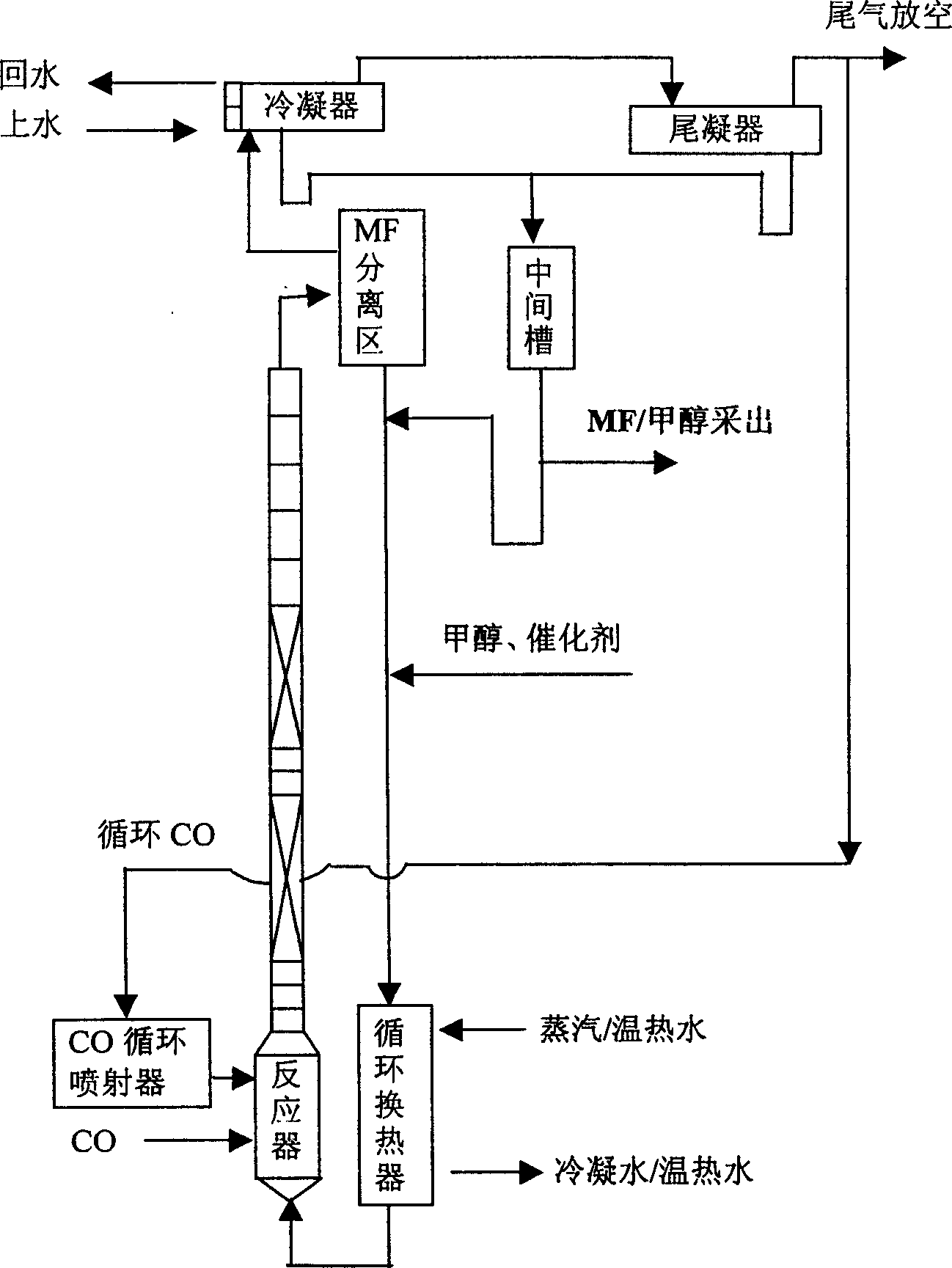

[0024] According to attached figure 1 , on the basis of the existing methyl formate reactor, the top of the reactor is provided with a MF separation zone with structured packing or trays, the top outlet of the MF separation zone is connected to the inlet of the condenser, and the gas phase outlet of the condenser is connected to the The gas phase inlet of the tail condenser is connected, and its liquid phase outlet is connected with the liquid phase outlet of the tail condenser, connected with the inlet of the middle tank, and connected with the reactor through a U-shaped tube; the other outlet of the tail condenser is connected with the tail gas venting control The system is connected and connected with the inlet of the CO circulation injector, the outlet of the CO circulation injector is connected with the inlet of the bottom of the reactor, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com