Composition comprising itraconazole for oral administration

A technology of itraconazole and a composition is applied in the field of an oral composition, which can solve the problems of itraconazole being difficult to disperse, the dissolution rate of itraconazole being low, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

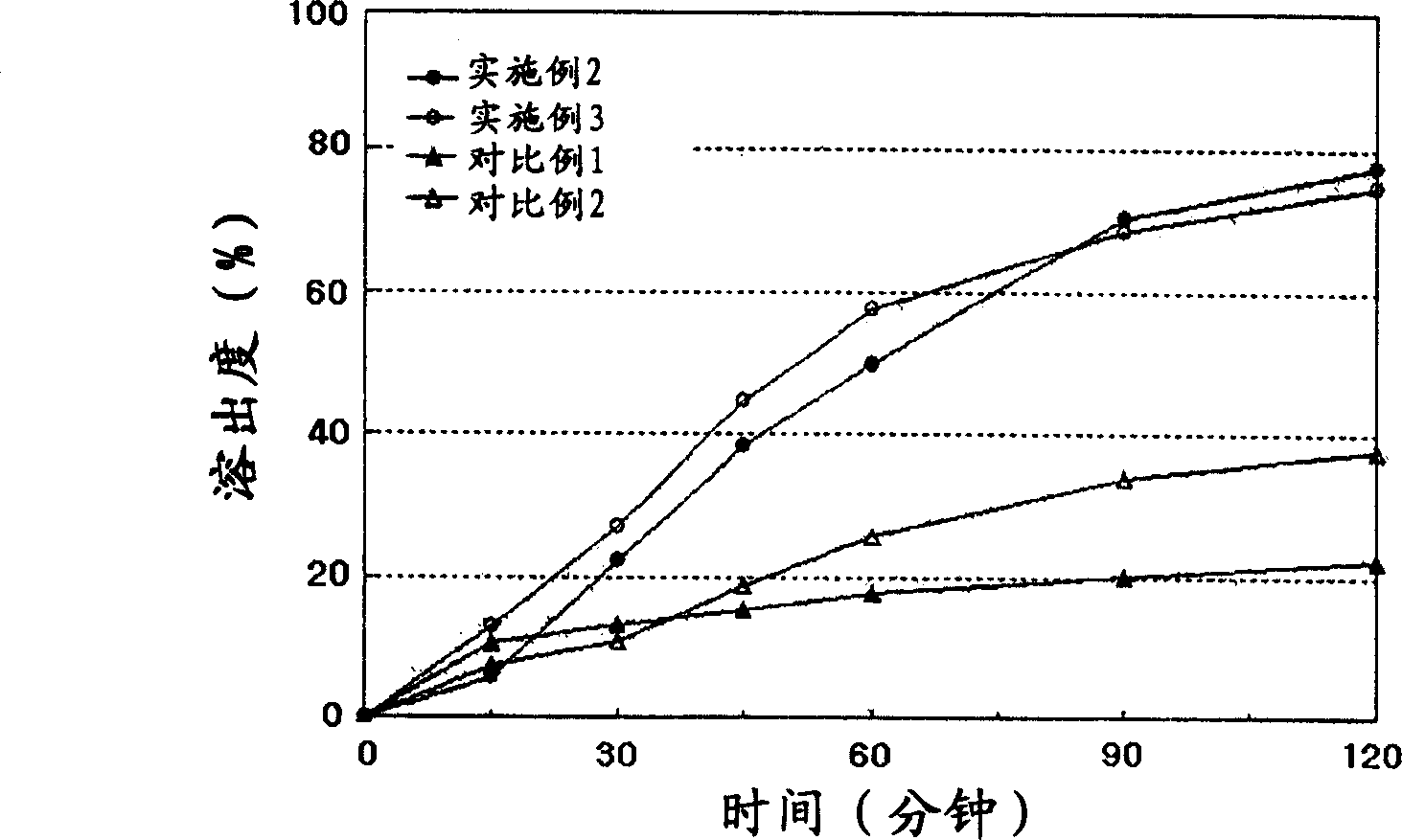

Examples

Embodiment 1

[0052] One hundred grams of the raw material itraconazole preparation (Sigma Chemical) was dissolved in 1,000 g of dichloromethane. Then, 22.2 g of citric acid as an absorption enhancer and 100 g of hydroxypropyl methylcellulose (Dow Chemical, weight average molecular weight of 10,000 to 1,500,000) were fully dissolved in 2,000 g of dichloromethane / ethanol (1:1, v / v) In mixed solvents. A spray dryer (B-191 mini spray dryer, Buchi Co., Switzerland) was used to spray the itraconazole solution and the mixture solution of hydroxypropyl methylcellulose and citric acid to form itraconazole dispersed in A solid dispersion in hydroxypropyl methylcellulose and citric acid to produce a white amorphous powder. The weight ratio of itraconazole: hydroxypropyl methylcellulose: citric acid is 45:45:10.

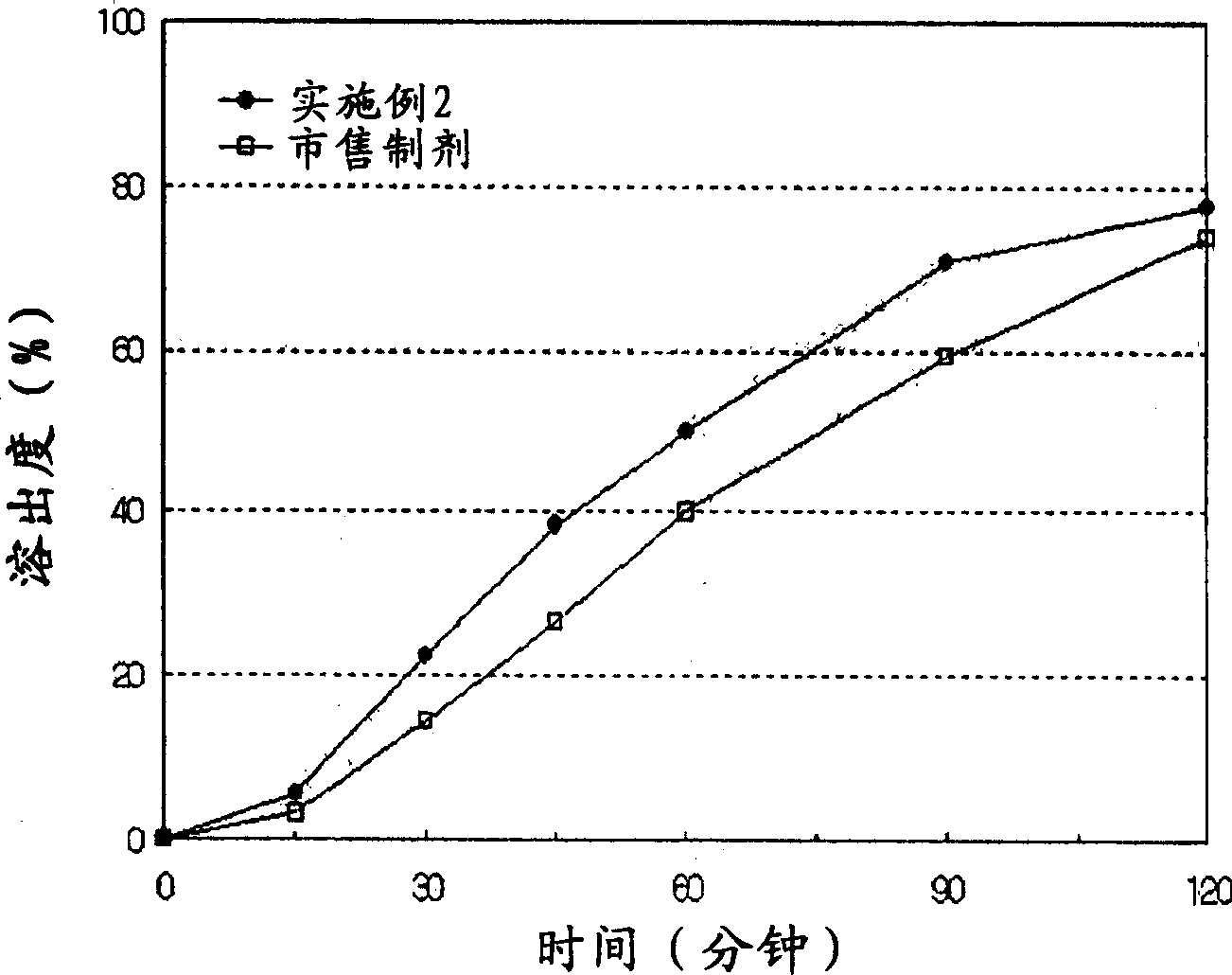

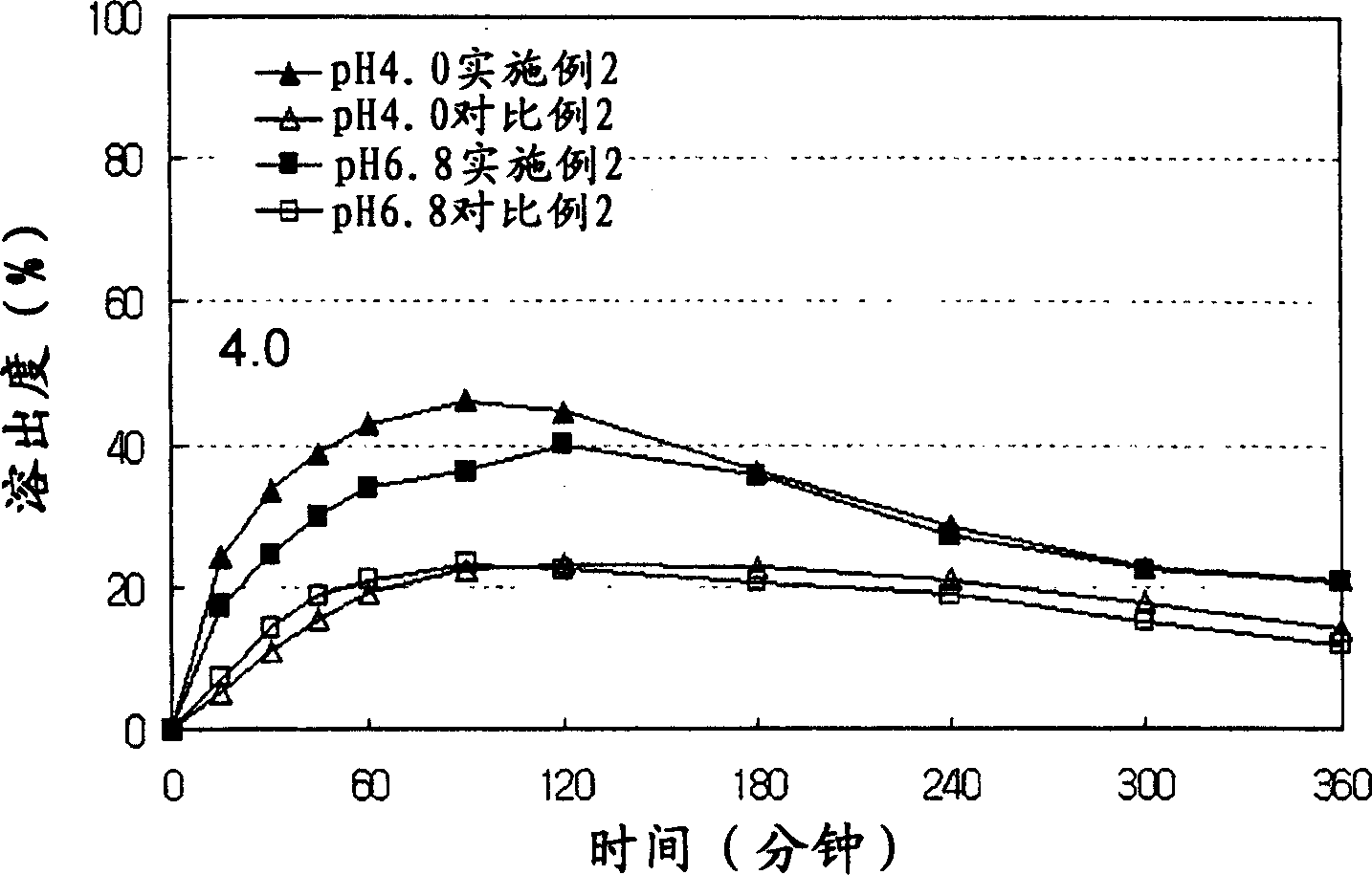

Embodiment 2

[0054] The itraconazole solid dispersion prepared in Example 1 and colloidal silica were sieved through a 30-mesh sieve and thoroughly mixed. Then, other components except magnesium stearate and talc in Table 1 below were added thereto, mixed, dried and granulated, and passed through a 25-mesh sieve to obtain uniform-sized granules. Subsequently, magnesium stearate and talc were added and mixed thoroughly to form the mixture into tablets. 120 g of Opadry AMB (Colorcon) was added to 546 g of pure water and mixed thoroughly to prepare a coating liquid. Using a tablet coating machine (SFC-30FN automatic coating machine, Sejong Pharmatech, South Korea), keeping the inlet temperature at 60~70℃ and the outlet temperature at 40~43℃, apply the coating solution to the prepared tablets In addition, each tablet is coated with 20mg of coating liquid.

[0055] Itraconazole solid dispersion

Embodiment 3

[0057] The itraconazole solid dispersion prepared in Example 1 and the components in Table 2 below were used to prepare tablets. The tablets were prepared and coated in the same way as in Example 2.

[0058] Itraconazole solid dispersion

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com