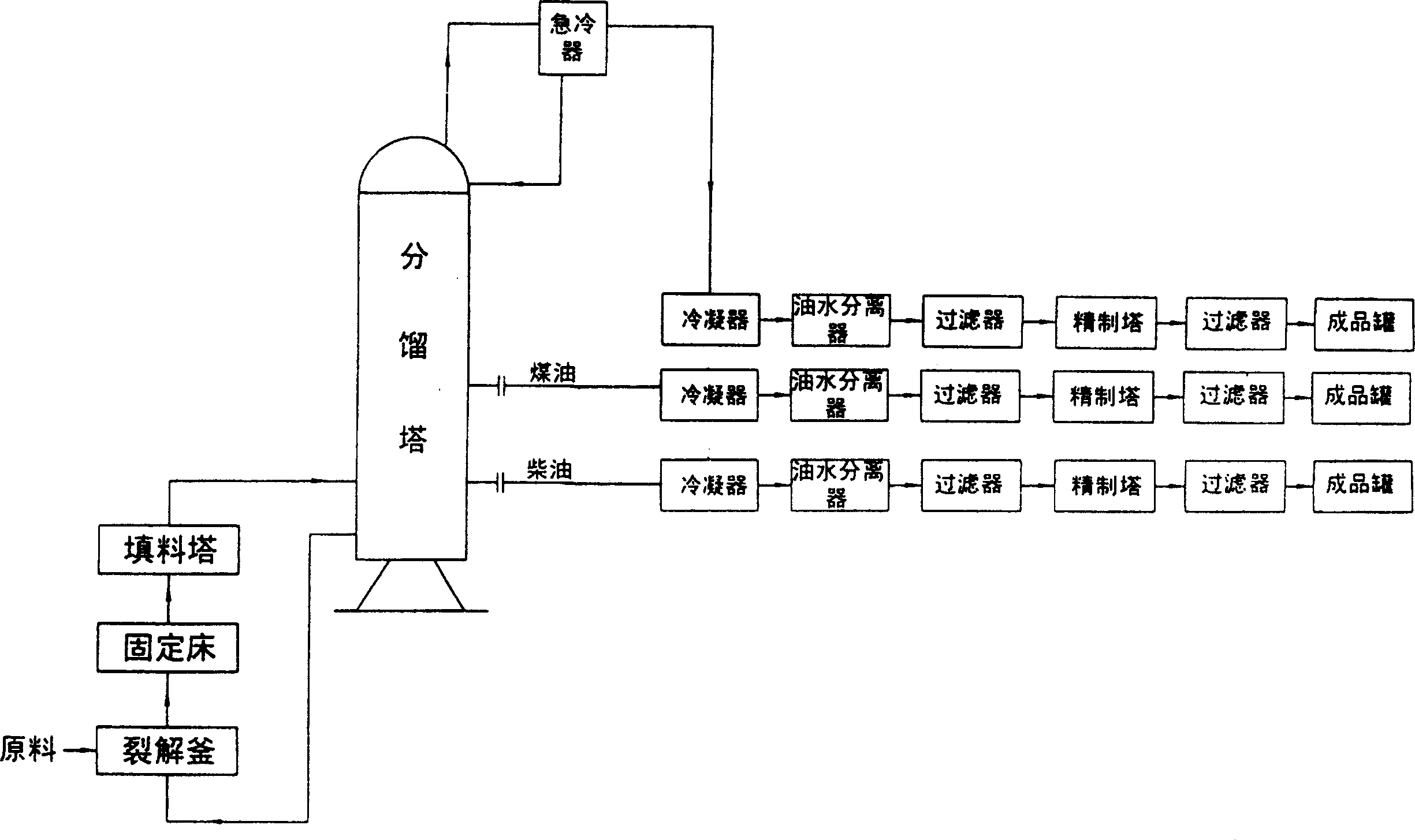

Method for reducing finished product mobile oil and refining gasoline and diesel from waste mobile oil and its apparatus thereof

A waste oil and diesel technology, applied in the petroleum industry, cracking, lubricating composition and other directions, can solve the problems affecting the popularization and application of technology, long production cycle, poor oil quality, etc., and achieve shortened production cycle, good oil quality, Low carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

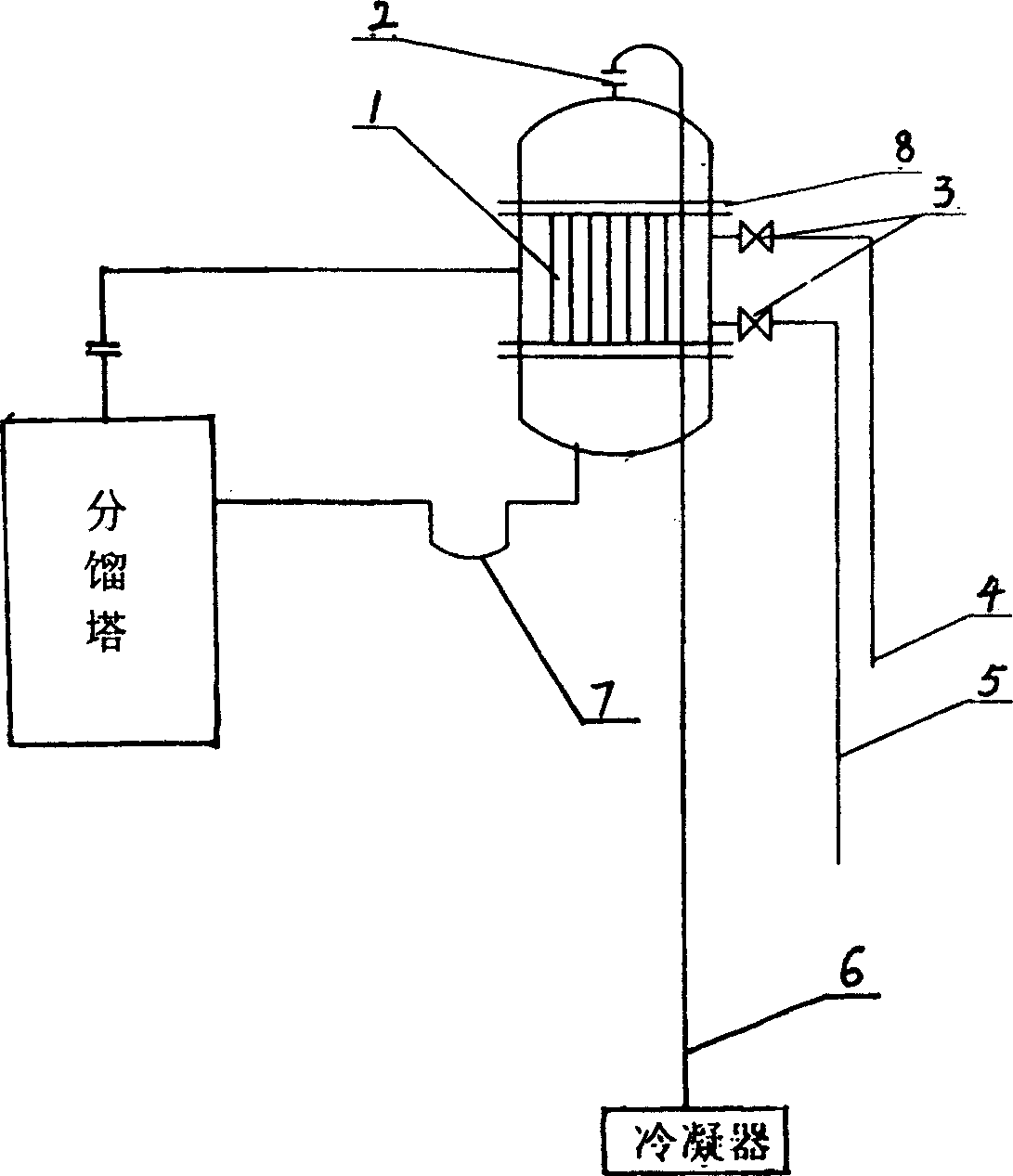

[0019] The waste engine oil enters the cracking tank, where catalytic cracking is carried out. The catalyst is made by adsorbing the active component zinc chloride on the granular aluminum oxide carrier by impregnation method. The temperature in the kettle was gradually increased from normal temperature to 460°C, and gas components were collected from 60°C. Add quartz stone and sand together with the raw materials in the cracking kettle, the quartz stone is 1% of the weight of the cracked raw material, and the sand is 0.2% of the weight of the cracked raw material. The gas fraction obtained by cracking enters the fixed bed, and the fixed bed is composed of coke layer, Pall ring, adsorbent layer and catalyst layer from the bottom up. The thickness of the coke layer is 20-50 cm. The adsorbent adopts stone bar adsorbent. , the thickness is 60-100 cm, the catalyst adopts 5A molecular sieve, and the thickness is 8-120 cm. The gas components obtained after passing through the fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com