Infrared imaging sensor and its vacuum packing method

An image sensor and infrared technology, applied in radiation control devices and other directions, can solve problems such as affecting the sensitivity of infrared image sensors of sensors, complex manufacturing process, etc., and achieve the effects of improving sensitivity and service life, simplifying packaging steps, and increasing the amount of configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The infrared image sensor and its vacuum packaging method of the present invention can not only simplify the steps of the packaging process required for the infrared image sensor, but also properly install the getter in the infrared image sensor, so that the infrared image sensor can reach the required vacuum degree. Requirements, thereby improving its sensitivity and service life. The following will clearly illustrate the concept of the present invention with the drawings and detailed description.

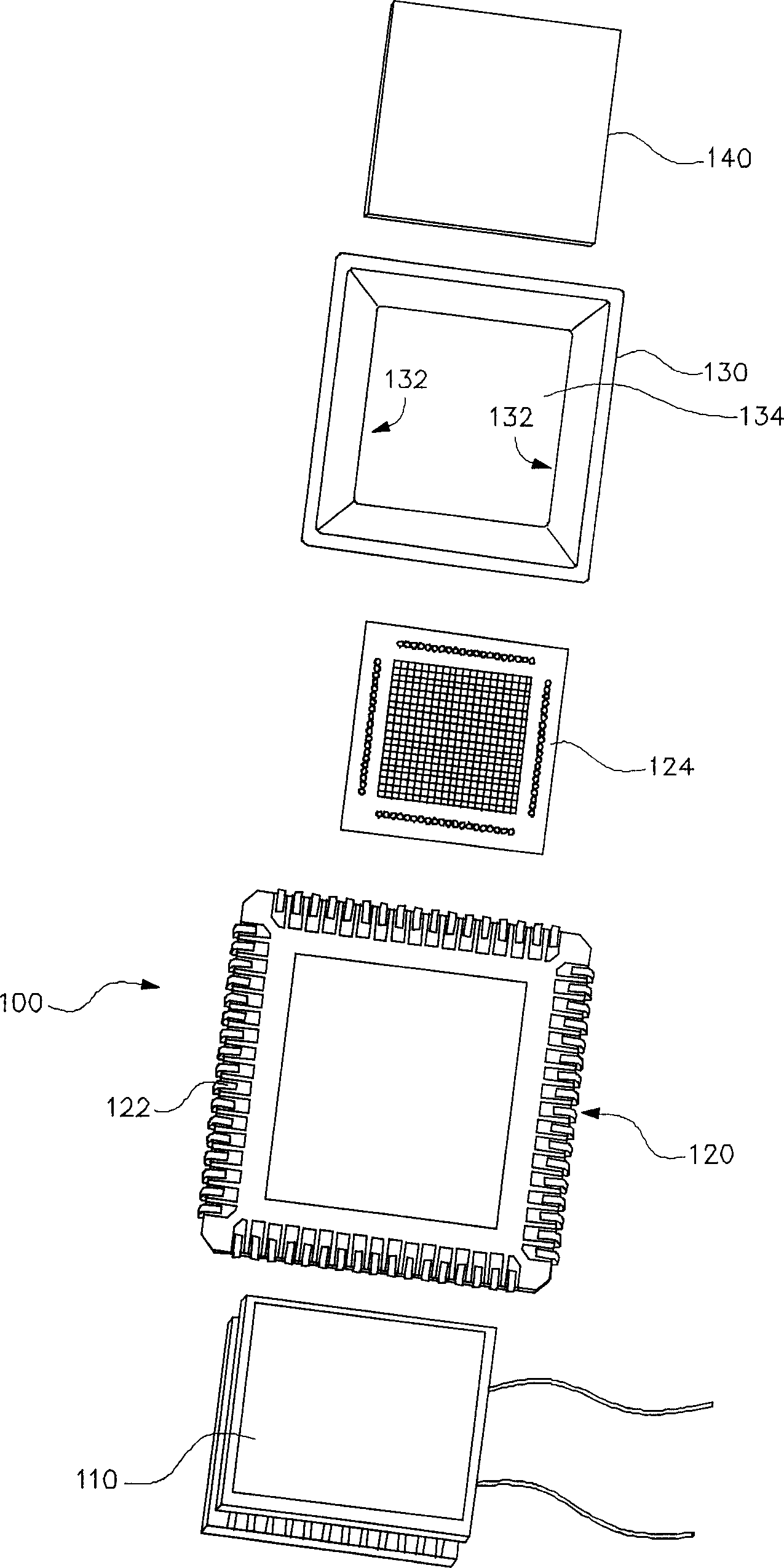

[0037] figure 1 It is a three-dimensional schematic diagram of parts of the infrared image sensor of the present invention. As shown in the figure, the infrared image sensor 100 of the present invention includes a filter 140 , an upper cover 130 , a base 120 and a thermoelectric temperature stabilizer 110 . The filter 140 is located above the upper cover 130 and is used to close the opening 134 of the upper cover 130 to maintain the vacuum of the infrared image sensor 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com